Low-shrinkage phenolic moulding compound

A phenolic molding compound and low-shrinkage technology, which is applied in the field of thermosetting plastics, can solve the problems of low shrinkage characteristics and lack of reference, and achieve the effect of improving strength and shrinkage resistance and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

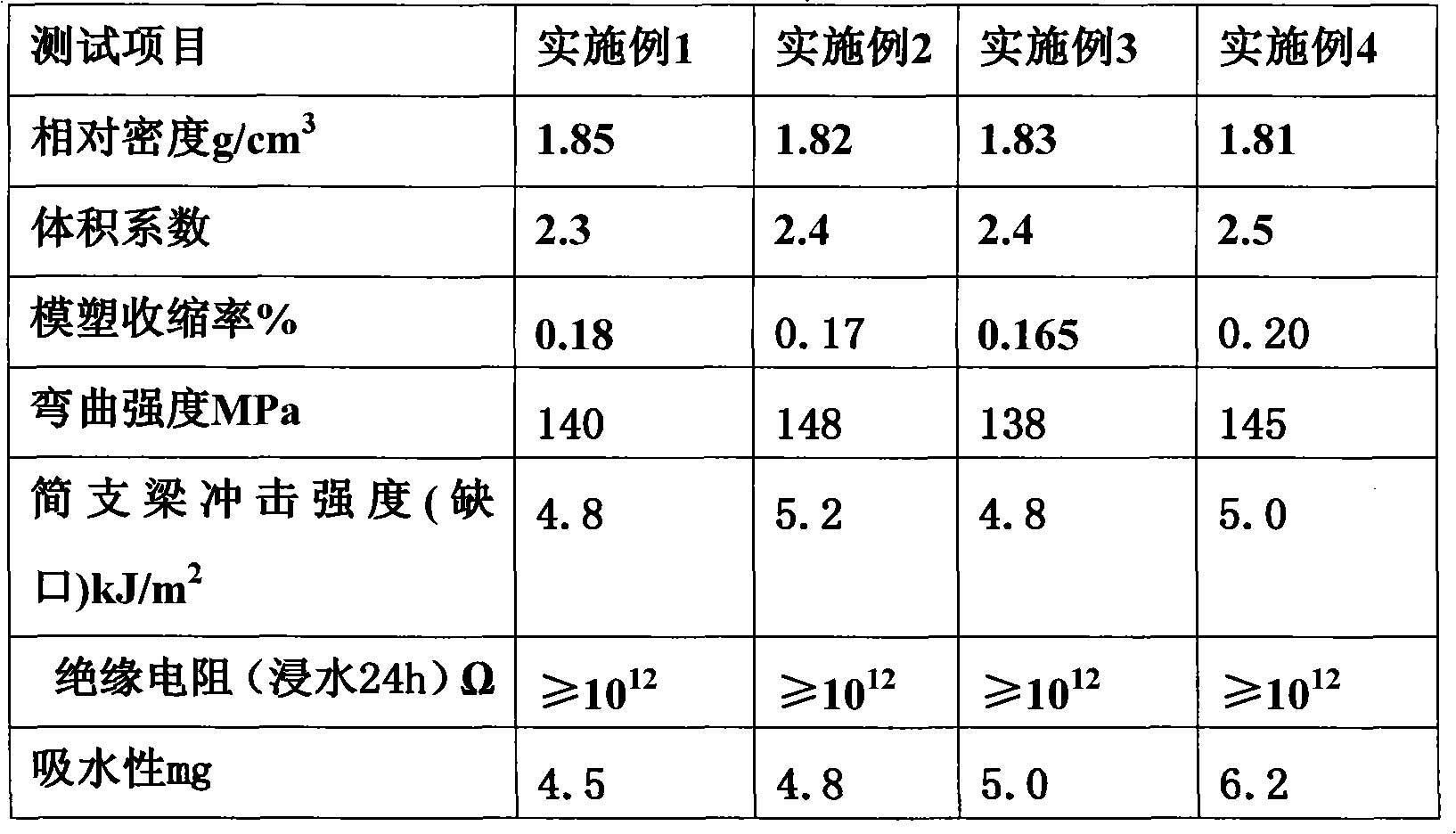

Examples

Embodiment 1

[0028] 28.0 parts of thermoplastic novolac resins;

[0029] 2.0 parts of epoxy resin;

[0030] 5.0 parts of hexamethylenetetramine;

[0031] Alkali-free chopped glass fiber (length 3mm, diameter 11-13μm) 35.0 parts;

[0032] Cotton fiber (length is 1mm) 5.0 parts;

[0033] 15.0 parts of nano calcium carbonate;

[0034] 1.0 parts of silane coupling agent;

[0035] Zinc stearate 1.0 parts;

[0036] 1.3 parts of stearic acid;

[0037] 1.5 parts of magnesium oxide;

[0038] 2.0 parts of polyvinyl acetate;

[0039] Ink 1.4 parts.

[0040] During implementation, the thermosetting novolak molding resin and epoxy resin produced by the acid method are first pulverized to obtain powdery resin, and the various raw materials weighed above are mixed in a kneader with the powdery resin according to the formula requirements (kneading) to obtain the kneaded material, then the kneaded material is masticated on two rollers, the temperature is 95 ℃, masticated for 6min, after being shee...

example 2

[0042] 20 parts of thermoplastic novolac resins;

[0043] 5.0 parts of liquid phenolic resin;

[0044] 4.0 parts of hexamethylenetetramine;

[0045] Alkali-free chopped glass fiber (length 2.5mm, diameter 11-13μm) 50.0 parts;

[0046] Cotton fiber (length 0.8mm) 1.0 parts;

[0047] 4.3 parts of nanoscale talcum powder;

[0048] 10.7 parts of nanometer mica powder;

[0049] 0.5 part of titanate coupling agent;

[0050] 1.2 parts of aluminum stearate;

[0051] 0.5 parts of ethylene bis stearic acid amide;

[0053] 0.1 parts of slaked lime;

[0054] 3.0 parts of methyl methacrylate;

[0055] Ink 0.5 parts.

[0056] All the other are the same as the description to embodiment 1.

example 3

[0058] 35.0 parts of thermoplastic novolac resins;

[0059] 4.0 parts of thermosetting phenolic resin;

[0060] 3.0 parts of melamine resin;

[0061] 3.0 parts of unsaturated polyester;

[0062] 8.0 parts of hexamethylenetetramine;

[0063] Alkali-free chopped glass fiber (length 3.5mm, diameter 11-13μm) 30.0 parts;

[0064] Cotton fiber (length 1.2mm) 3.0 parts;

[0065] 10.0 parts of nanoscale talcum powder;

[0066] 5.0 parts of nanometer mica powder;

[0067] 5.0 parts of nanometer calcium carbonate;

[0068] 5.0 parts of nanoscale barium sulfate;

[0069] 0.5 part of silane coupling agent;

[0070] 0.8 part of titanate coupling agent;

[0071] 1.0 parts of calcium stearate;

[0072] Zinc stearate 1.5 parts;

[0073] 1.5 parts of magnesium stearate;

[0074] 1.0 parts of magnesium oxide;

[0075] 1.0 parts of slaked lime;

[0076] 0.25 part of polymethyl methacrylate;

[0077] 0.25 parts of polystyrene;

[0078] Ink 2.0 parts.

[0079] All the other are the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com