Ammonia escape prevention device in desulfurization and denitrification of flue gas by using ammonia process

A technology for ammonia desulfurization and ammonia escape, which is applied in the field of ammonia escape prevention devices in flue gas ammonia desulfurization and denitrification, which can solve the problems of single adjustment method for ammonia escape and increased content of sulfur dioxide and nitrogen oxides, and achieve a simple and stable overall structure Good performance, easy operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

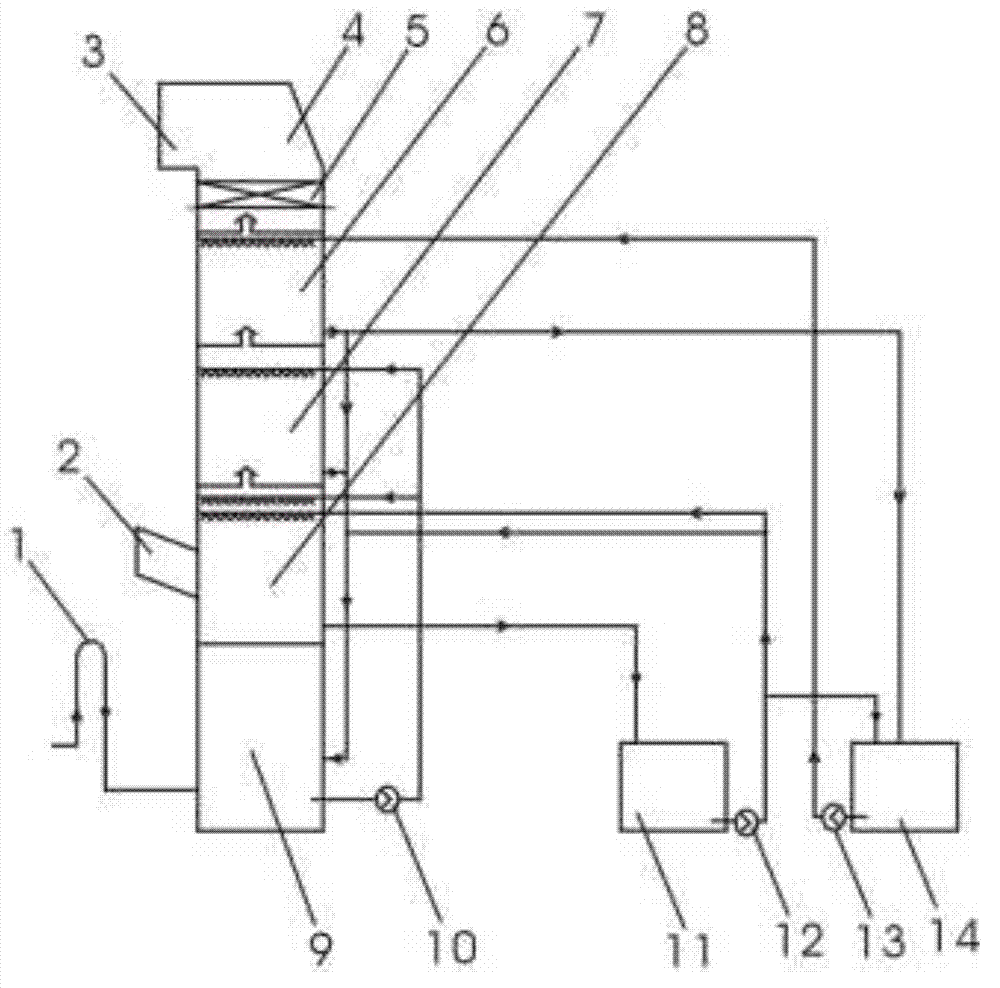

[0007] Now refer to the attached figure 1 , described as follows in conjunction with the embodiment: the device for preventing ammonia from escaping in the flue gas ammonia desulfurization and denitrification according to the present invention includes oxidizing air 1, original flue gas inlet 2, net flue gas outlet 3, desulfurization tower 4, demister 5 , ammonia washing section 6, absorption section 7, concentration section 8, oxidation section 9, primary circulation pump 10, circulation tank 11, secondary circulation pump 12, circulation ammonia washing pump 13 and circulation ammonia washing tank 14. The oxidizing air 1 is connected to the oxidation section 9 through pipelines, the oxidation section 9 is connected upward to the concentration section 8, the concentration section 8 is provided with a raw flue gas inlet 2, the concentration section 8 is connected upward to the absorption section 7, and the absorption section 7 is upwardly connected to the washing The ammonia s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com