High temperature resistant heat-conducting silica gel sheet and preparation method thereof

A heat-conducting silicone sheet, high-temperature-resistant technology, applied in the field of high-temperature-resistant heat-conducting silicone sheet, can solve the problems that the temperature resistance can only reach 200°C, and the long-term temperature resistance can only reach 160°C

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preparation of thermally conductive compound

[0031] Add the specified amount of vinyl-terminated polydimethylsiloxane and vinyl-terminated methylphenyl silicone oil into the planetary mixer, mix evenly, and then add heat-conducting powder, heat-resistant additives, coupling agents and other auxiliary materials in three times. The agent was stirred, and the temperature was raised to 150°C at the same time, and the temperature began to drop after stirring for 3 hours. Add hydrogen-containing silicone oil and inhibitor sequentially at room temperature. After stirring well, set aside.

[0032] take shape

[0033] Use a double-roll calender or a multi-roll calender to put the prepared rubber on the PET coated with a release agent, and at the same time, cover the upper layer with PET coated with a release agent, and calender to the required thickness. Or heated and vulcanized in an integrated heating tunnel.

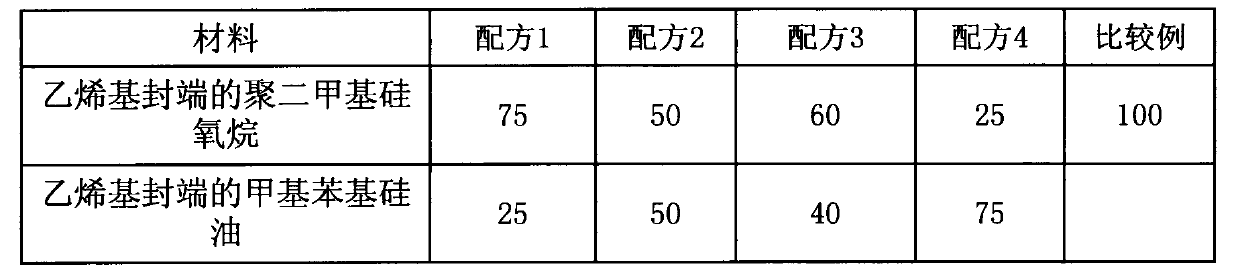

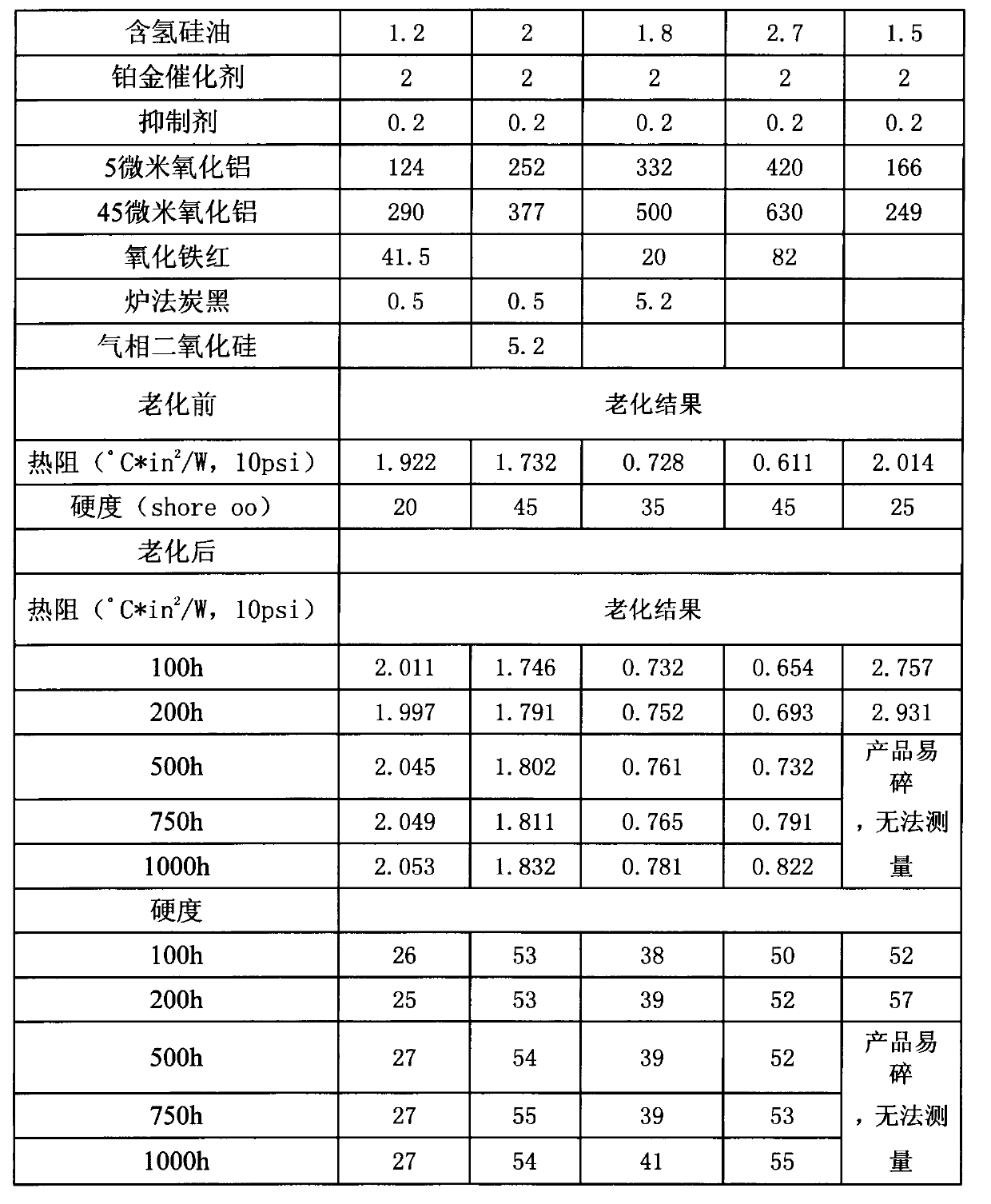

[0034] Different formulations were used to prepare high-temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com