Catalyst with dispersed single platinum atoms and preparation method of catalyst

A technology of atomic dispersion and catalyst, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low utilization rate of platinum, high cost of platinum and platinum preparation, and achieve higher utilization rate, lower preparation cost, and high oxygen reduction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the catalyst of platinum single atom dispersion provided by the invention, concrete steps are as follows:

[0034] Step 1. Add the carbon carrier and the platinum compound into the nitric acid solution, then stir and reflux for more than 4 hours in an oil bath above 40°C; the oil bath reflux temperature is preferably 40-100°C, more preferably 80°C; the reflux time is preferably 4~10h, more preferably 6h;

[0035] Step 2. Drying the refluxed liquid sample obtained in step 1 above 35° C. to obtain a solid powder; the drying temperature of the rotary evaporating is preferably 35-65° C., more preferably 60° C.;

[0036] Step 3. Mix the solid powder obtained in step 2 with a non-metallic heteroatom reagent, put it into an agate mortar and grind it for more than 0.1h, then put it into a tube furnace, and process it at 800°C for more than 0.5h to obtain platinum single Atomically dispersed catalyst; the grinding time of the reaction raw material is p...

Embodiment 1

[0039] Add 0.1g of Black Pearl 2000 (hereinafter referred to as BP2000) to 30mL of 6mol / LHNO 3 50mL round-bottomed flask, and then add 130μL of platinum containing 3.102mg·mL to the flask -1 H 2 PtCl solution, the flask was placed in an oil bath with an oil bath temperature of 80°C to reflux for 6h.

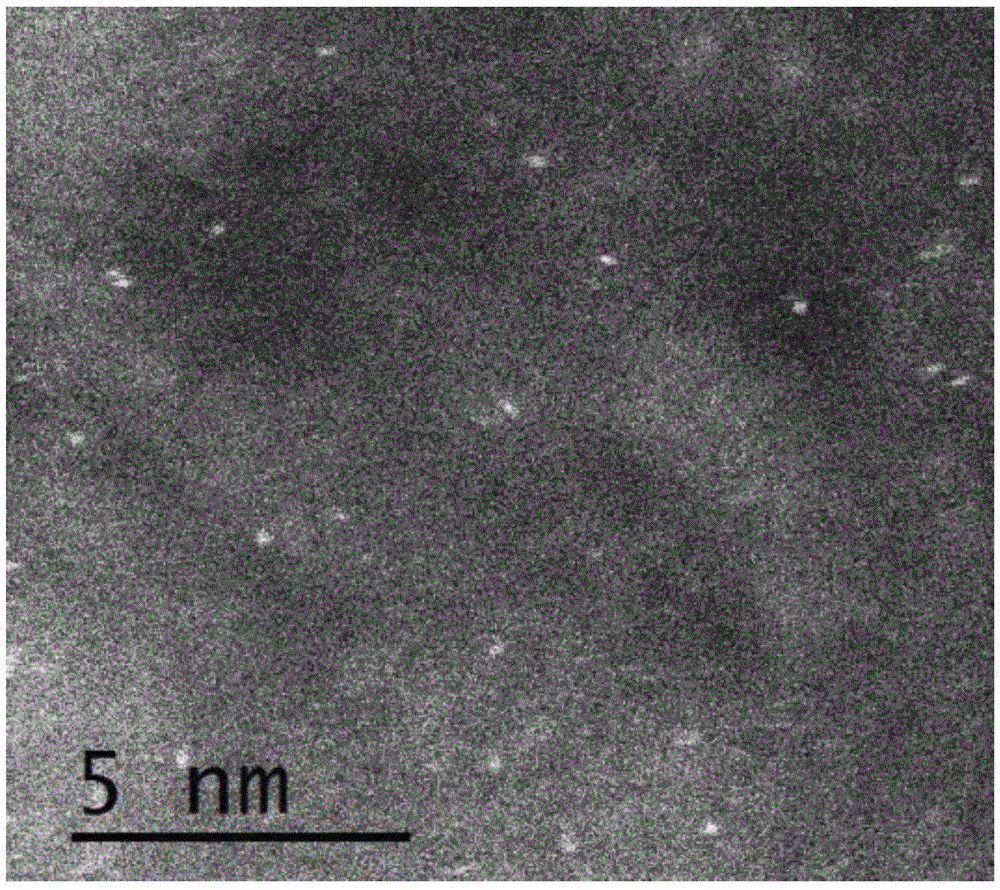

[0040] The refluxed suspension was transferred to a 200 mL Erlenmeyer flask, and dried at 60° C. by a rotary evaporator to obtain a platinum-doped carbon black powder. Then put the obtained carbon black powder and 1 g of melamine into an agate mortar and mix them, after grinding for 0.5 h, place the obtained uniformly mixed powder in a single-temperature zone slide rail furnace, and treat at 950° C. for 1 hour at high temperature to obtain Nitrogen-doped platinum single-atom dispersed catalyst powder, after the temperature drops to room temperature, is taken out and set aside. Through XPS test, the ratio of carbon, nitrogen and platinum atoms is 10:1:0.02. Such as figure 1 S...

Embodiment 11、0

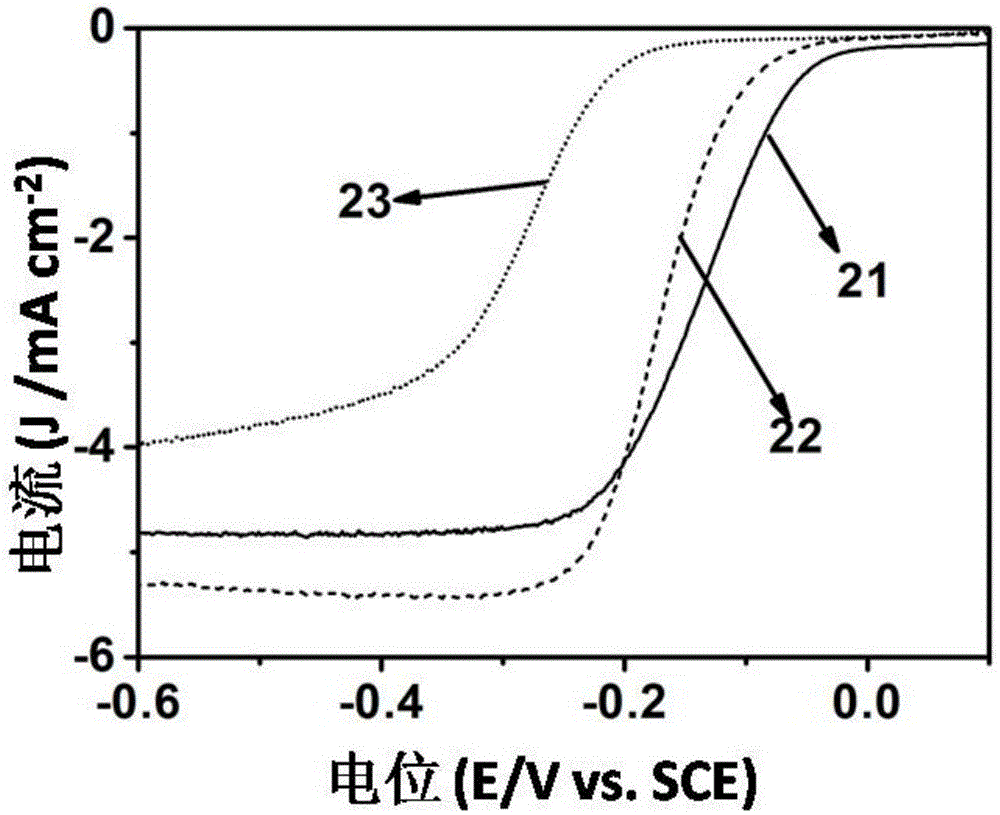

[0042] Test in the KOH electrolyte of embodiment 1.1,0.1mol / L:

[0043] 10 μL of the solution was drip-coated on the rotating disk electrode, and after drying at room temperature, a thin-film electrode was obtained; a three-electrode system with an SCE electrode as a reference electrode and a Pt sheet as a counter electrode, in a 0.1mol / In the KOH solution of L, a linear voltammetry test was carried out using a rotating disk electrode, and the scanning speed was 5mV / s. For the results, see figure 2 Curve 21 in . Depend on figure 2 It can be seen that the oxygen reduction onset potential of the catalyst prepared in Example 1 is 8mV, and its half-wave potential is -134mV. Compared with the commercial Pt / C catalyst with a platinum content of 20% in Example 1, the oxygen reduction onset potential and half-wave potential are more positive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com