Preparation and applications of supported palladium catalyst using MOFs derived carbon-based material as carrier

A technology of supported palladium and carbon-based materials, applied in the direction of carbon compound catalysts, catalysts, physical/chemical process catalysts, etc., can solve the problems of easy deactivation and difficult separation of noble metal catalysts, and achieve good cycle stability and high specific surface area , easy-to-implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Weigh 0.064g of palladium chloride and 0.384g of polyvinylpyrrolidone and dissolve them in a mixture of 600mL of methanol and 20mL of deionized water, reflux at 70°C for 5h to obtain Pd nanoparticles.

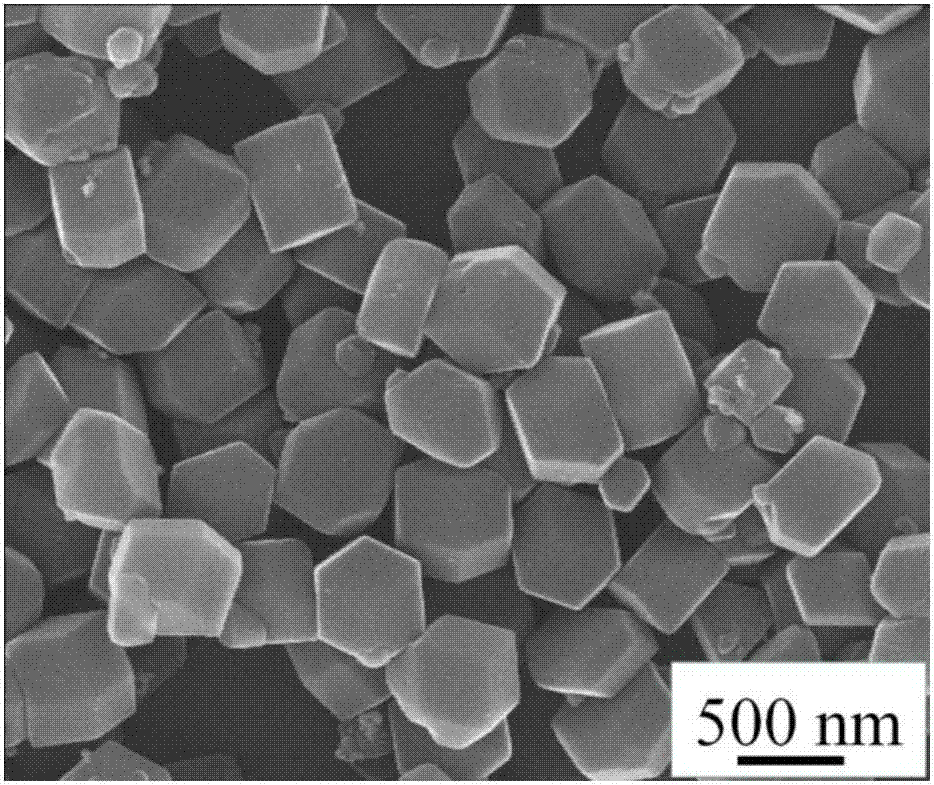

[0023] Step 2: Weigh 6.600g of 2-methylimidazole, 5.000g of cobalt nitrate hexahydrate and 4.000g of polyvinylpyrrolidone and dissolve them in 350mL of methanol solution, and add 150mL of the Pd nanoparticle solution prepared in step 1 into the above mixture , magnetically stirred for 2 hours, then left at room temperature for 24 hours, then centrifuged with methanol, activated, and vacuum-dried at 60°C for 8 hours to obtain Pd@ZIF-67.

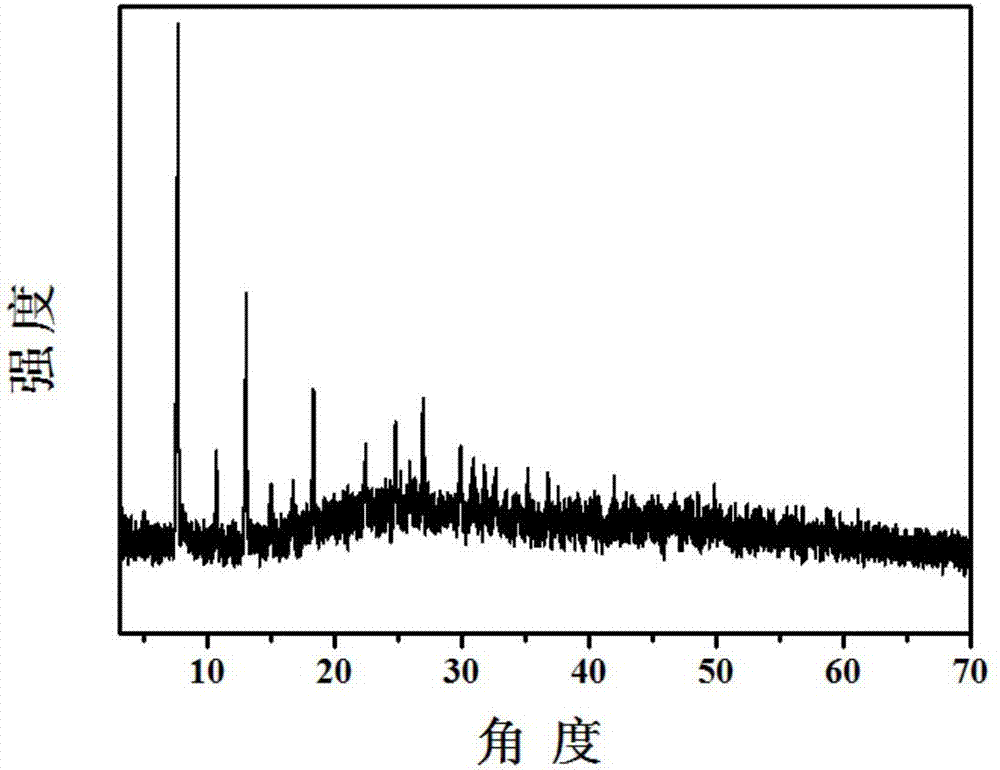

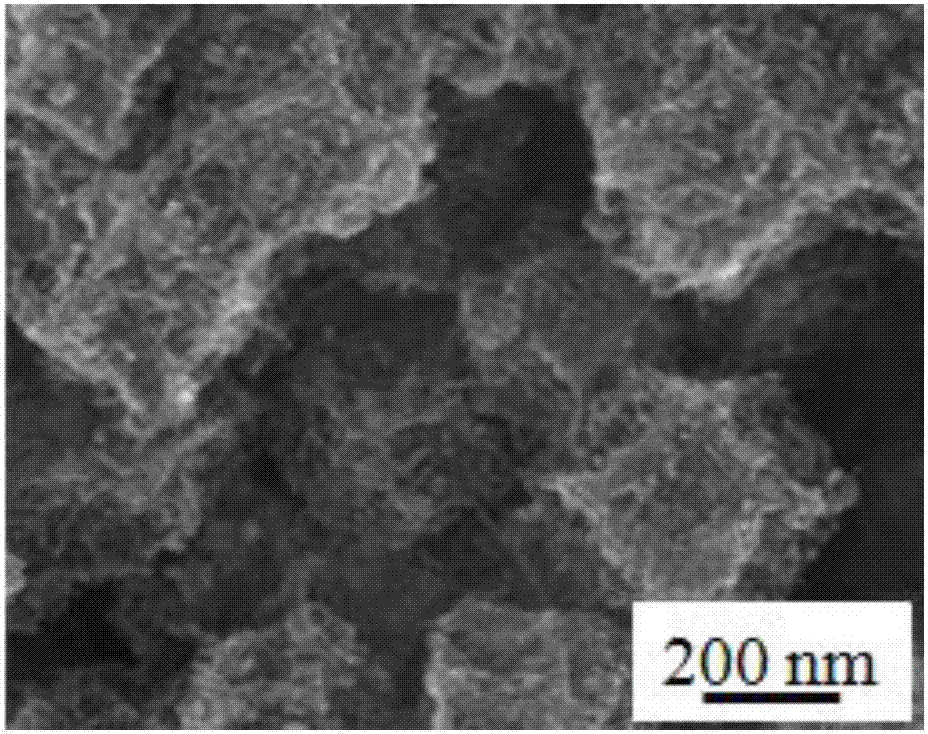

[0024] Step 3: Weigh 0.200 g of Pd@ZIF-67 prepared in Step 2, place it in a mortar and grind for 10 min, and under nitrogen protection, heat up to 800 °C for 3 h at a heating rate of 2 °C / min to prepare a nitrogen-doped The supported palladium metal nanoporous composite material (Pd@Co / CNT) wrapped by heterogeneous carbon nanotub...

Embodiment 2

[0026] Step 1: Weigh 0.064g of palladium chloride and 0.384g of polyvinylpyrrolidone and dissolve them in a mixture of 600mL of methanol and 20mL of deionized water, reflux at 70°C for 5h to obtain Pd nanoparticles.

[0027] Step 2: Weigh 6.600g of 2-methylimidazole, 5.000g of cobalt nitrate hexahydrate and 4.000g of polyvinylpyrrolidone and dissolve them in 250mL of methanol solution, and add 250mL of the Pd nanoparticle solution prepared in step 1 to the above mixture , magnetically stirred for 2 hours, then left at room temperature for 24 hours, then centrifuged with methanol, activated, and vacuum-dried at 60°C for 8 hours to obtain Pd@ZIF-67.

[0028] Step 3: Weigh 0.200 g of Pd@ZIF-67 prepared in Step 2, place it in a mortar and grind it for 10 min, and under the condition of nitrogen protection, heat up to 900 °C for 2 h at a heating rate of 2 °C / min to prepare a nitrogen-doped The supported palladium metal nanoporous composite material (Pd@Co / CNT) wrapped by heterogene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com