Supported palladium catalyst and preparation method thereof

A technology of catalyst and metal palladium, which is applied in the field of supported metal palladium catalyst and its preparation, can solve the problems of large pressure drop in the system of industrial production equipment, poor catalyst activity selectivity, short catalyst renewal period, etc., and achieve bed pressure drop reduction Small size, high mechanical strength, and enhanced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

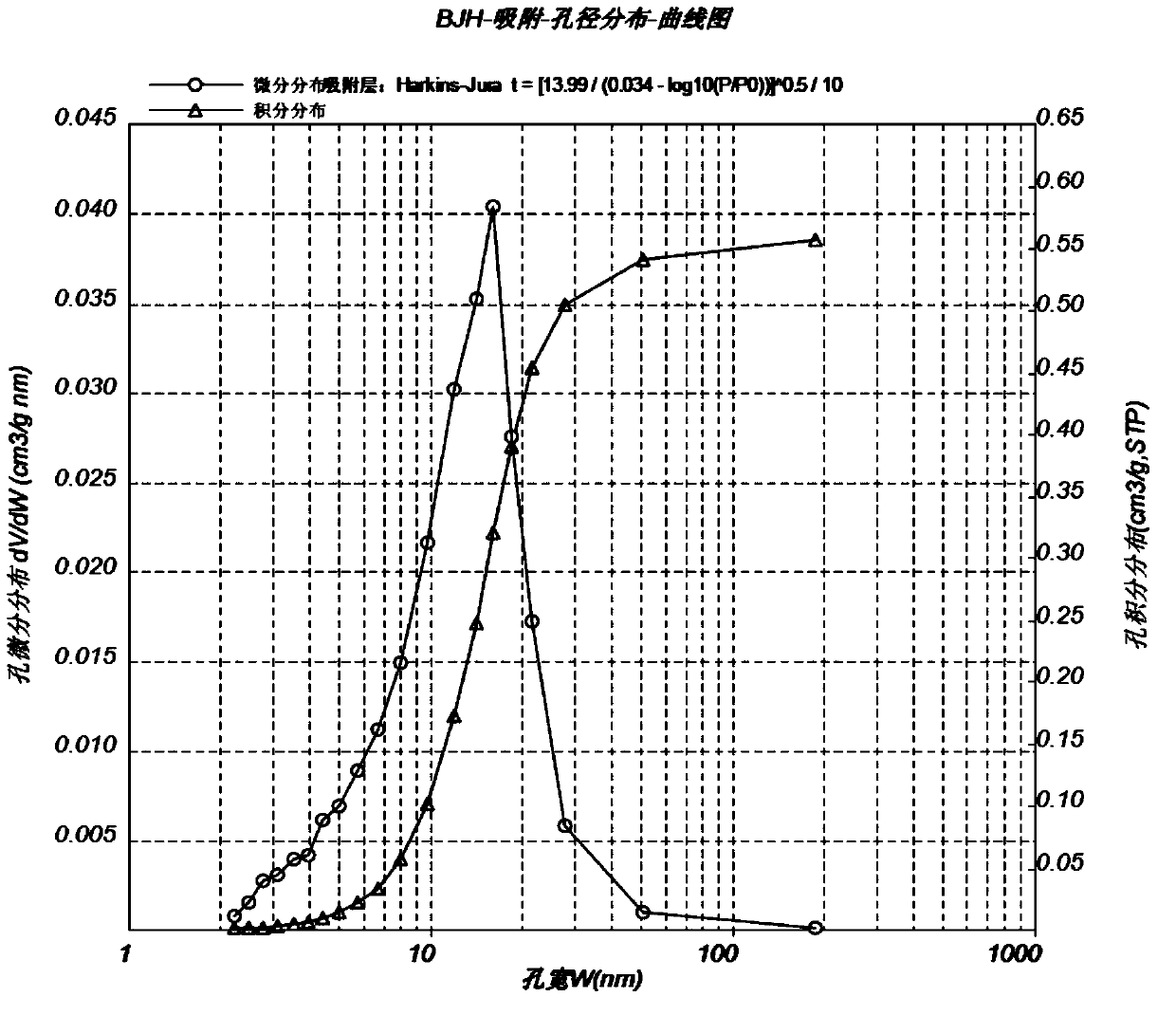

[0039] The raw material of the catalyst carrier is alumina (Shandong Aluminum Plant of Aluminum Corporation of China), with a specific surface area of 50-500m 2 / g, the pore volume is 0.8-1.2ml / g, Na 2 O≤0.1%, Fe 2 o 3 ≤0.02%. Using this as raw material, add pore-forming agent ammonium carbonate and polyvinyl alcohol and knead, extrude into a clover shape under the pressure of 16MPa, and carry out temperature programming at a uniform speed (1-2°C / min), 80-120 ℃ drying for 8 hours, 500-600 ℃ baking 6 hours, become γ-alumina.

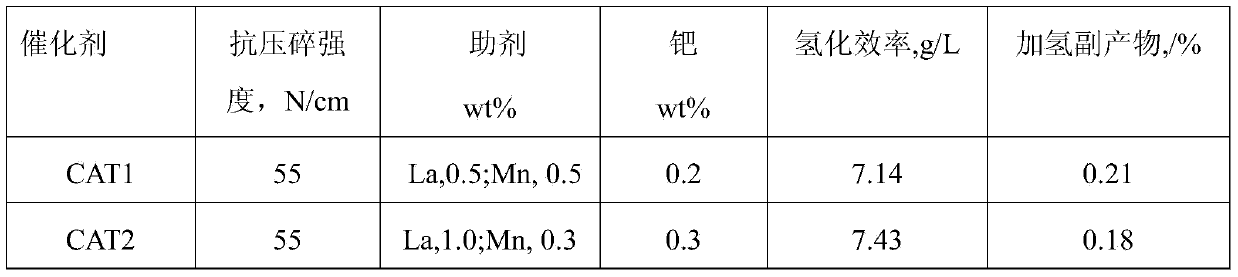

[0040] Weigh 50g Φ2.5×5-8mm clover-shaped alumina and add 0.58g La(NO 3 ) 3 La(NO 3 ) 3 After soaking in the solution for 10 minutes, vacuum-dry at 80°C for 2h, and then calcined at 900°C for 5h. Get 7ml of palladium-containing solution again, add 1.0g50wt% Mn(NO 3 ) 2 The aqueous solution was heated to 90°C, and the clover-shaped alumina treated with lanthanum was poured into it, vacuum-reduced and impregnated for 10 minutes, then the catalys...

Embodiment 2

[0041] Example 2 Prepare Pd / Al with a palladium loading of 0.3wt% in the same manner as in Example 1, a manganese loading of 0.3wt%, and a lanthanum loading of 1.0wt%. 2 o 3 Catalyst, the catalyst number is CAT-2.

Embodiment 3

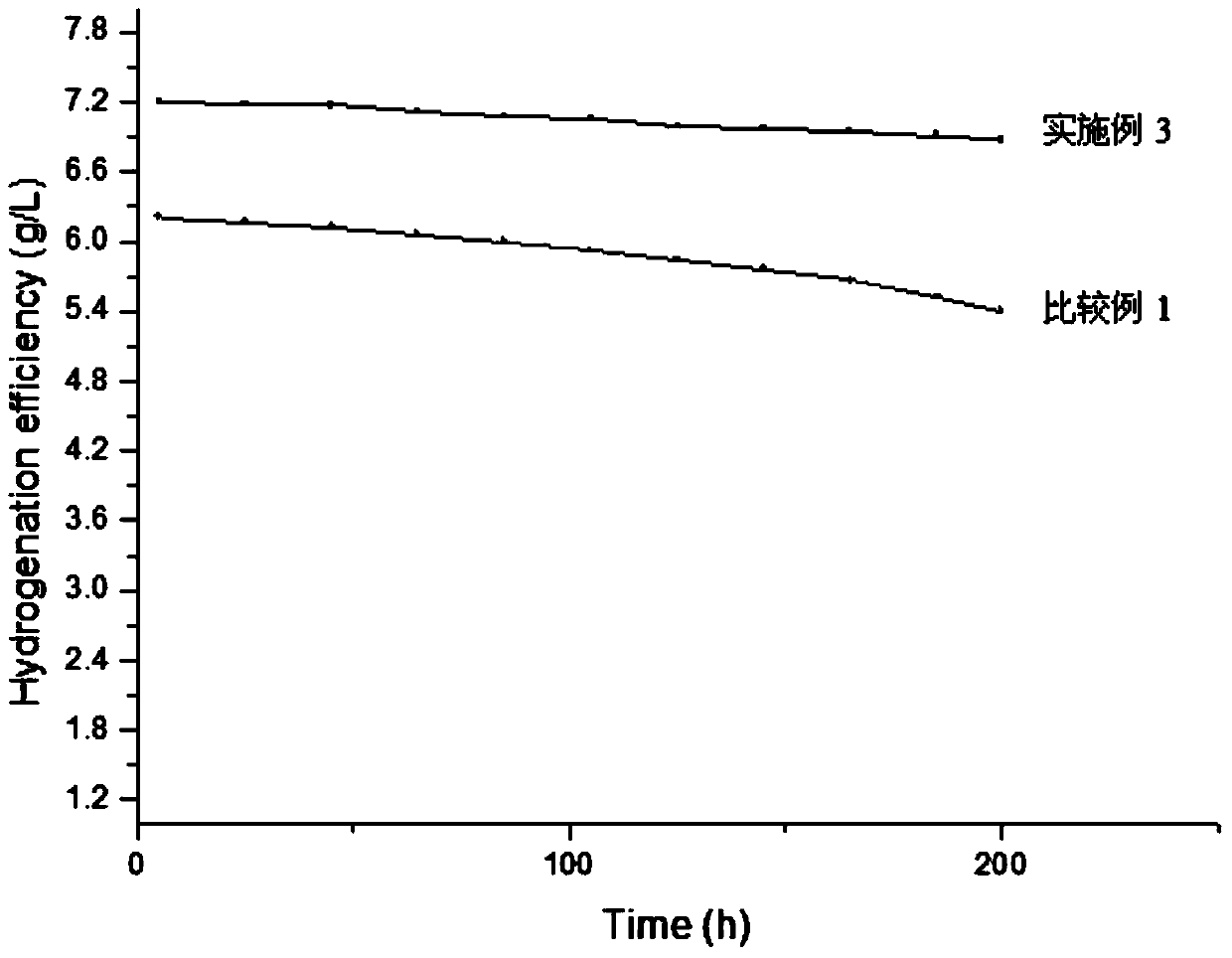

[0042] Example 3 In the same way as in Example 1, the palladium loading was 0.5wt%, the manganese loading was 0.2wt%, and the lanthanum loading was 1.5wt% Pd / Al 2 o 3 Catalyst, the catalyst number is CAT-3. This catalyst is used in the catalytic hydrogenation of anthraquinone to produce hydrogen peroxide. The catalytic activity changes with time. See the appendix. figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com