Method for preparing small-size nickel-cobalt lithium manganate precursor

A technology for nickel-cobalt lithium manganate and nickel-cobalt lithium manganate, which is applied in the field of preparation of small-sized nickel-cobalt lithium manganate precursors, can solve the problem of harsh requirements on raw materials and equipment, difficult to control product morphology, and unsuitable for industrialized production, etc. problems, to achieve the effect of convenient equipment requirements, regular morphology and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

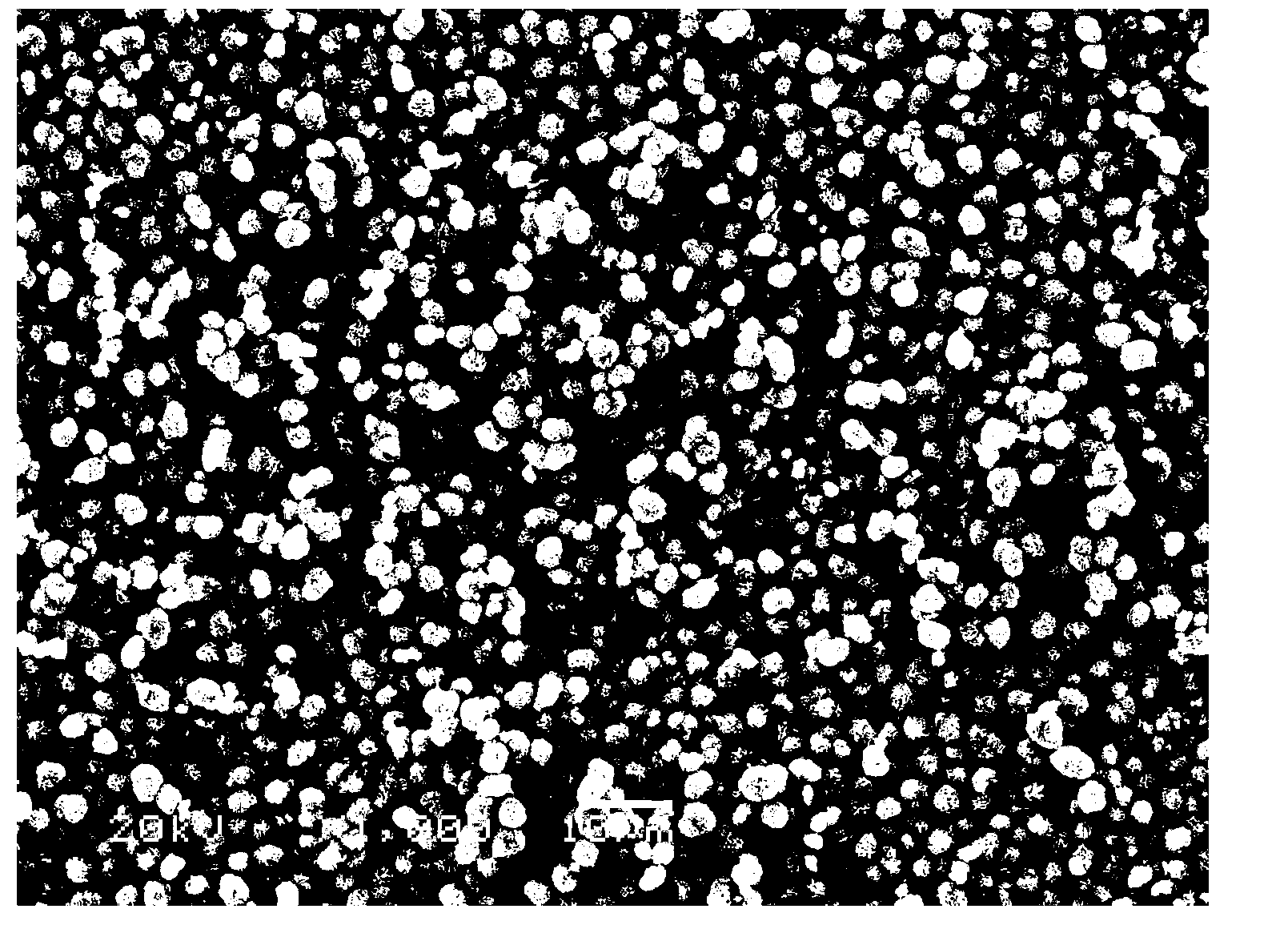

[0030] A kind of preparation method of precursor of nickel cobalt lithium manganese oxide of small particle size comprises the following steps:

[0031] (1) Use the soluble salts of nickel, cobalt, and manganese nickel sulfate, cobalt sulfate, and manganese sulfate as raw materials, prepare the solution according to the molar ratio of nickel, cobalt, and manganese in the nickel-cobalt lithium manganate to be provided, and control The total concentration of nickel-cobalt-manganese in the mixed solution of prepared nickel-cobalt-manganese salt is at 2mol / L;

[0032] Precipitant adopts sodium hydroxide aqueous solution, and its molar concentration is 8mol / L, and in the sodium hydroxide aqueous solution, will add according to every liter of sodium hydroxide aqueous solution, add the polyethylene glycol of 8g as dispersant; Adopt ammonia water as complexing agent, control The ammonia concentration in it is 10mol / L.

[0033] Among them, nickel sulfate, cobalt sulfate, and manganese...

Embodiment 2

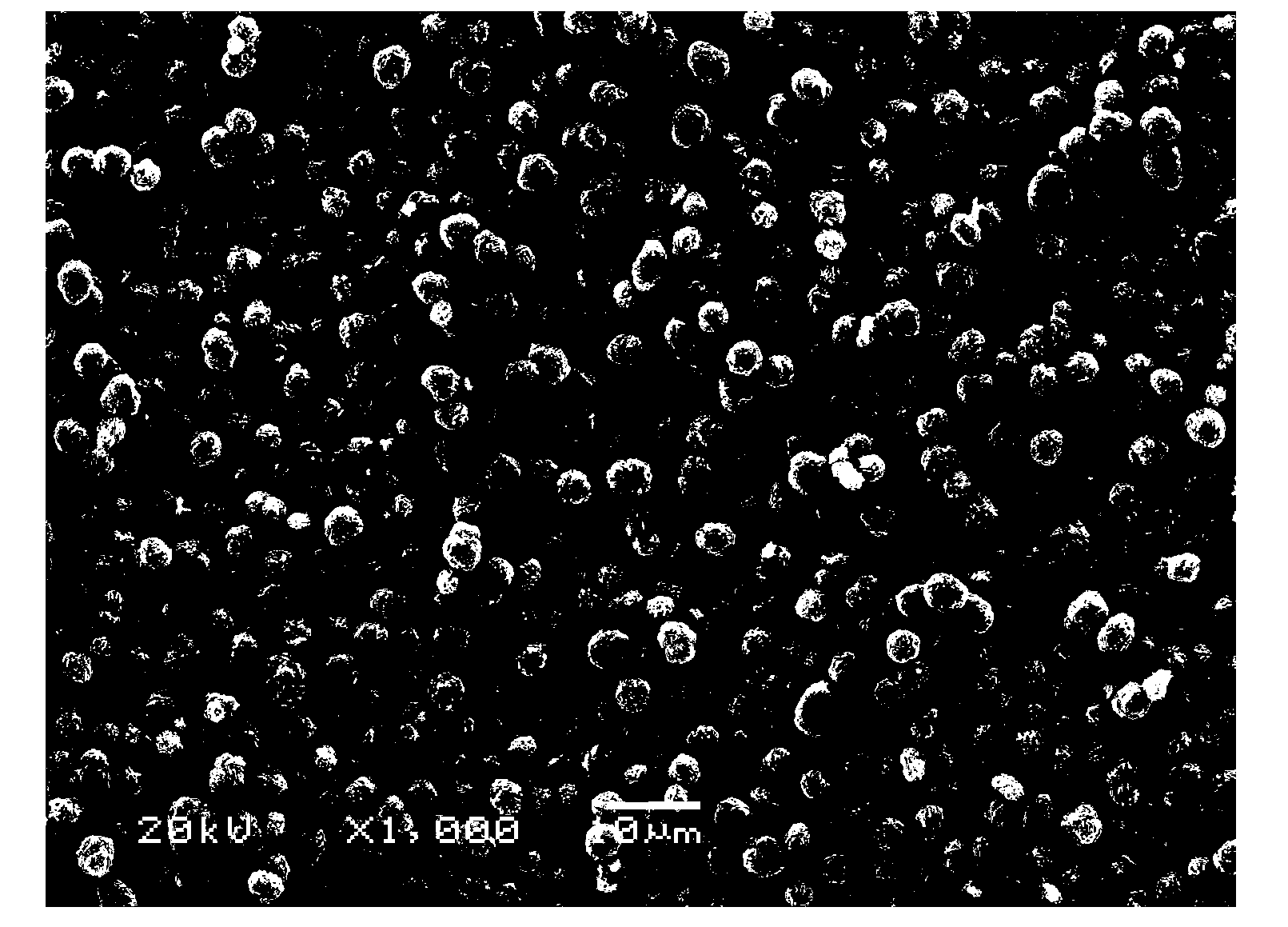

[0041] According to the Ni:Co:Mn molar ratio of 1:1:1, prepare a mixed aqueous solution of nickel chloride, cobalt chloride, and manganese chloride with a concentration of 2.0mol / L, and add lemon that accounts for 0.5% of the total moles of nickel, cobalt, and manganese. trisodium acid. The prepared solution goes through the steps of precision filtration, demagnetization, and nitrogen gas to discharge dissolved oxygen, and is stored at 40-50°C for use.

[0042] Prepare 8mol / L sodium hydroxide aqueous solution, and add 8g polyvinyl alcohol according to the volume of every liter sodium hydroxide aqueous solution. The prepared solution is used after precision filtration, demagnetization, and nitrogen gas discharge to discharge dissolved oxygen.

[0043] Prepare 10mol / L ammonia solution.

[0044] Add 30L of bottom water to the 100L reactor, the ammonia concentration in the bottom water is 0.5mol / L, adjust the pH of the bottom water to 11.5 with aqueous sodium hydroxide solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com