Soft magnetic composite powder and magnetic powder core preparation method thereof

A soft magnetic composite and composite powder technology, applied in the direction of magnetic materials, magnetic objects, metal processing equipment, etc., can solve the problems of high magnetic loss of iron-silicon powder cores, large-scale promotion restrictions, and high material costs, and achieve high cost performance and good performance. Comprehensive magnetic properties, improved bulk density and flowability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

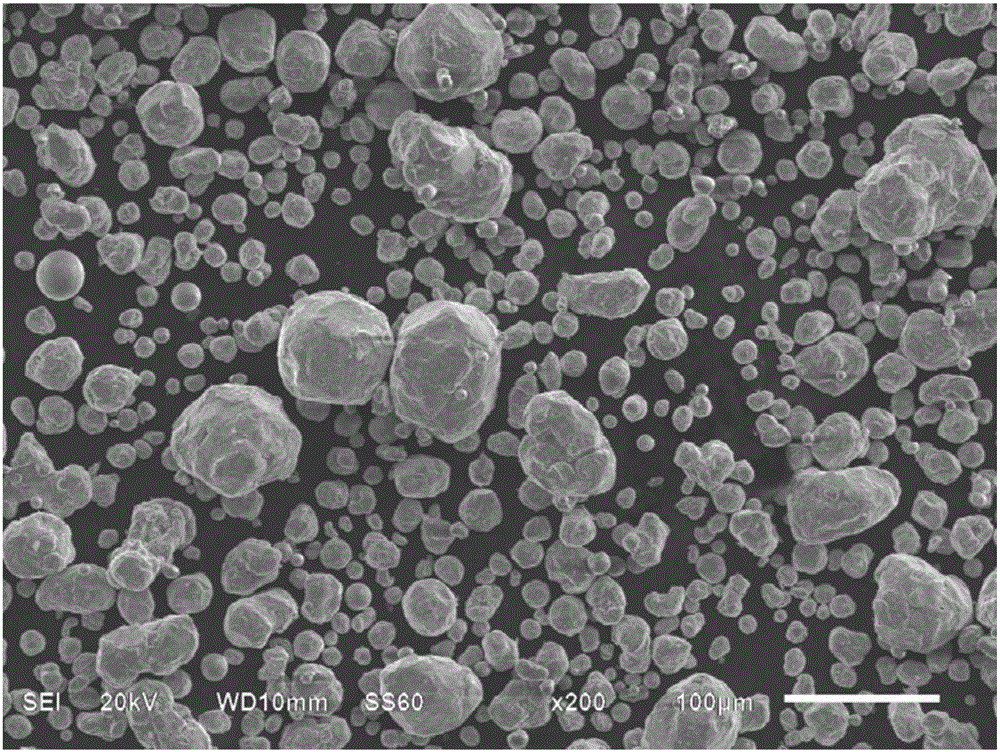

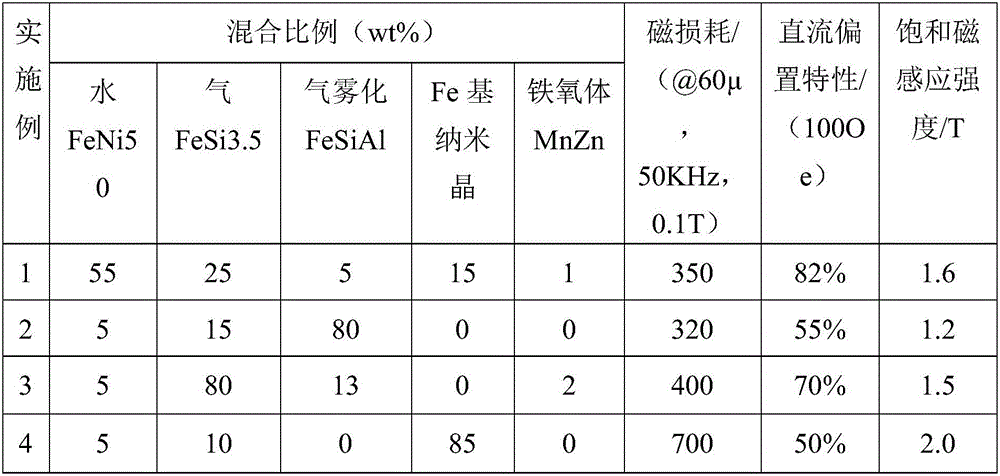

[0038] A kind of low-cost, low-loss FeNi50 soft magnetic composite powder and its magnetic powder core preparation method, the method is carried out according to the following steps:

[0039] First, according to the magnetic characteristics, the saturation magnetic induction of the material is required to be 1.6T, the DC bias characteristic is 82% (100Oe), and the magnetic loss is 3 . Through the linear calculation and composition optimization of the magnetic properties of different soft magnetic materials, it is necessary to select water atomized FeNi50, FeSi3.5 and FeSi9.5Al5.5, rapid quenching Fe-based nanocrystalline powder and MnZn ferrite as raw materials. The mass ratio is 55%:25%:4%:15%:1%. Among them, FeNi50 powder is preferably -100 / 150 mesh, FeSi9.5Al5.5 powder particle size is 200 / 325 mesh, FeSi3.5 and Fe-based amorphous powder particle size is -200 / 325 mesh and -500 mesh, MnZn ferrite Particle size 2 As an insulating agent, the mass proportions are respectively 0...

Embodiment 2

[0042] A kind of high DC bias characteristic FeSiAl soft magnetic composite powder and its magnetic powder core preparation method, the method is carried out according to the following steps:

[0043] First of all, according to the magnetic characteristics, the saturation magnetic induction of the material is required to be 1.2T, the DC bias characteristic is 55% (100Oe), and the magnetic loss is 3 . Through the linear calculation and composition optimization of the magnetic properties of different soft magnetic materials, it is necessary to select water atomized FeNi50, gas atomized FeSi3.5 and crushed FeSi9.5Al5.5 powders as raw materials, and the mass ratio of the above powders is 5%:15% :80%. Among them, the preferred FeNi50 and FeSi3.5 powders are -325 mesh and -500 mesh, and the crushing FeSiAl powder is -150 mesh. Shaping treatment is carried out for FeSiAl and water atomized FeNi50 powders by the crushing method, the feeding rate of the jet mill is 100Kg / h, and the tr...

Embodiment 3

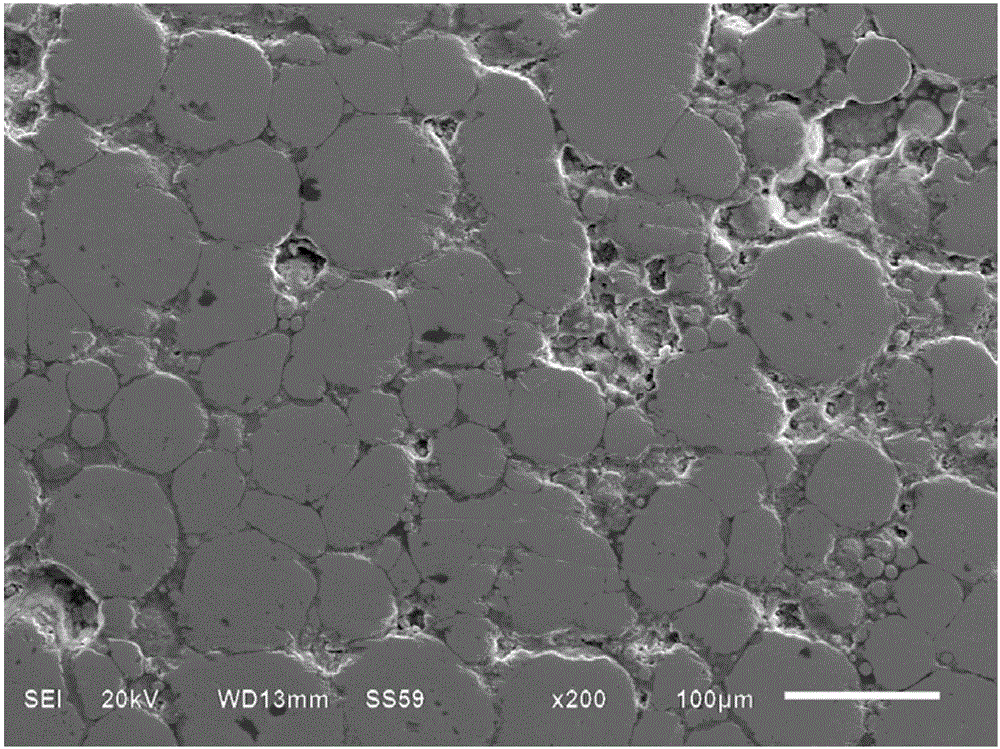

[0045] A kind of low-loss FeSi6.5 soft magnetic composite powder and its magnetic powder core preparation method, the method is carried out according to the following steps:

[0046] First, according to the magnetic characteristics, the saturation magnetic induction of the material is required to be 1.5T, the DC bias characteristic is 70% (100Oe), and the magnetic loss is 3 According to the performance requirements of different soft magnetic materials, through the linear calculation and composition optimization of the magnetic properties of different soft magnetic materials, it is necessary to select water atomized FeNi50, gas atomized FeSi6.5 and crushing method FeSi9.5Al5.5 and MnZn ferrite powder as raw materials, the above powder The mass ratio is 5%:80%:13%:2%. Among them, the preferred FeNi50 and FeSi6.5 powders are -325 mesh and -200 mesh, the crushing method FeSiAl powder is -150 mesh, and the particle size of MnZn ferrite powder is 2 As an insulating agent, add mass pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com