Method for preparing gold nanoparticles by annealing of gold film

A nanoparticle and gold preparation technology, applied in nanotechnology, metal material coating process, ion implantation plating, etc. Irregular appearance and other problems, to achieve the effect of no coating on the surface, regular appearance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Depositing Gold Nanofilms by Magnetron Sputtering

[0028] Cleaning glass substrate materials

[0029] The glass substrate material 1 is first cleaned with a detergent, and then ultrasonically cleaned with acetone, isopropanol, and alcohol for 30 minutes, 15 minutes, and 10 minutes in sequence. Blow dry with nitrogen after cleaning.

example 2

[0031] Depositing Gold Nanofilms by Vacuum Evaporation

[0032] Put the cleaned base material 1 on the sample platform of the vacuum evaporation chamber, take 0.0455g of gold wire with a purity of 99.99% and put it into the molybdenum boat as the evaporation source, and make the distance between the evaporation source and the sample platform Keep it around 56 cm. After the evaporation source and sample are placed, the cavity vacuum of the vacuum evaporation chamber is evacuated to 5×10 by mechanical pump and molecular pump. -4 Turn on the evaporation current and control the evaporation speed so that the complete evaporation time is 5 minutes. After evaporating, wait for cooling for about 10 minutes, open the cavity, and take out the sample. At this time, a layer of gold nano film 2 is uniformly deposited on the surface of the base material 1 .

Embodiment 3

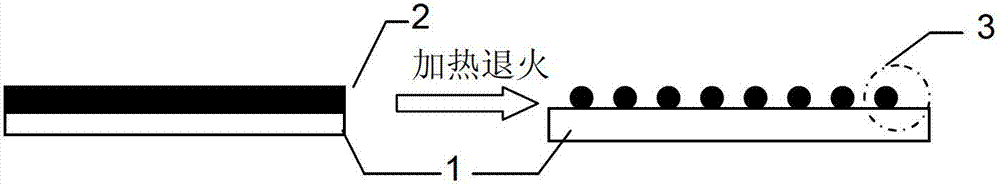

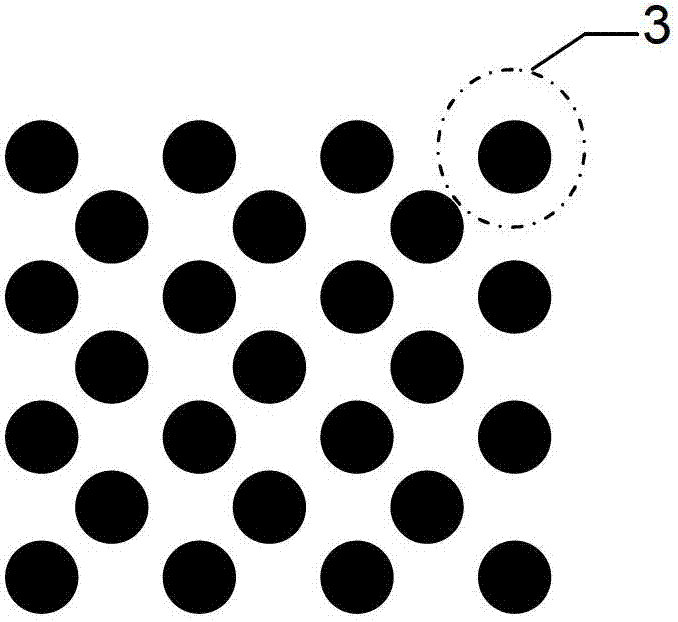

[0034] Preparation of gold nanoparticles by annealing method

[0035] After depositing a layer of gold nano film 2 on the base material 1 by magnetron sputtering and vacuum evaporation, before putting it into the annealing furnace, use a nitrogen gun to purge the sample several times to ensure that no dust is deposited on the sample base . Put it into the annealing furnace, and pump the vacuum of the annealing furnace to 1×10 -2 Then flow nitrogen gas to maintain normal pressure. The temperature in the furnace was evenly heated to 450 oC within 15 minutes by means of gradual heating, and maintained for 1 hour. After heating, continue to flow nitrogen and cool to room temperature. After the cooling is completed, the annealing furnace is opened to take out the sample. At this point, a layer of gold nanoparticles 3 is prepared on the base material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com