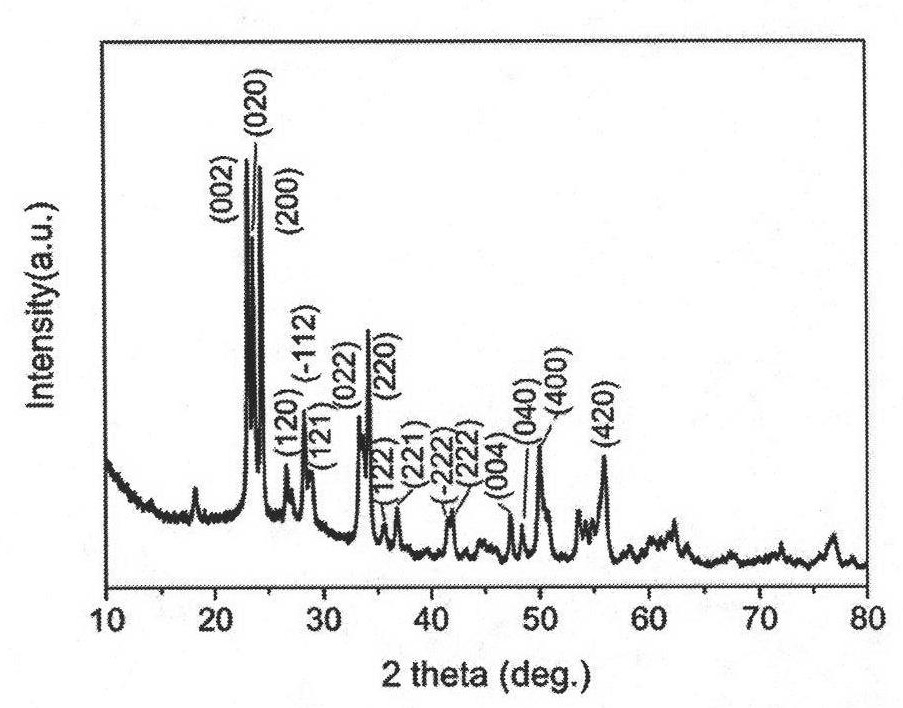

Method for preparing tungstic oxide nano-sheets

A technology of nanosheets and tungsten oxide, which is applied in nanostructure manufacturing, tungsten oxide/tungsten hydroxide, nanotechnology, etc., can solve few problems, achieve uniform particle size, low cost, and easy-to-operate process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

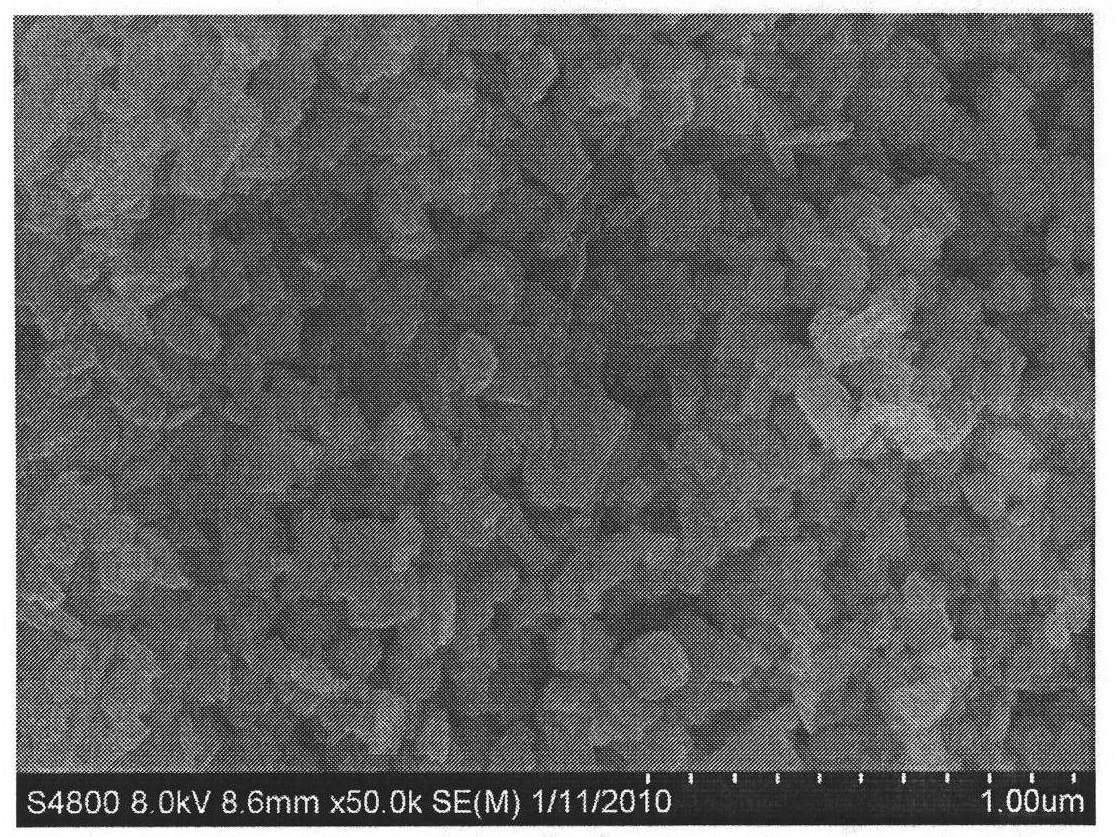

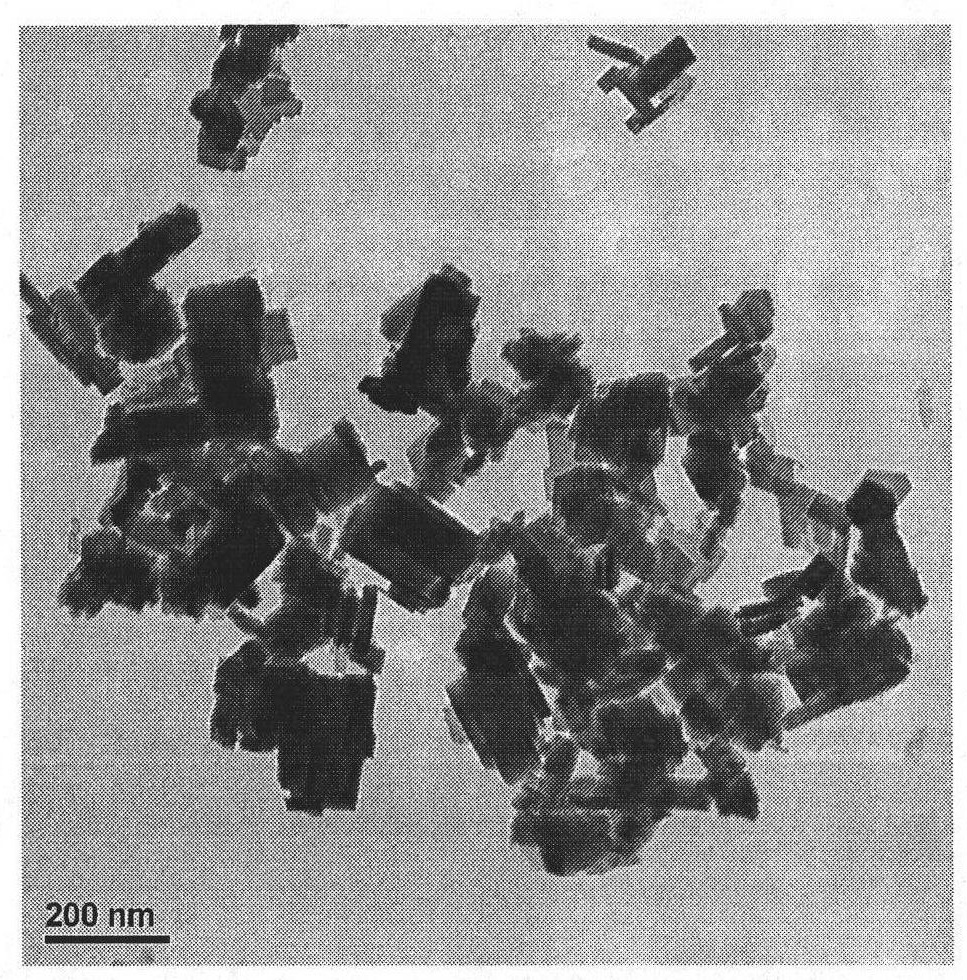

Embodiment 1

[0029] Slowly add 13g of tungsten powder into the mixed solution of 80ml of hydrogen peroxide and 8ml of deionized water, stir continuously in an ice-water bath until the tungsten powder is completely dissolved, and obtain a bright yellow peroxypolytungstic acid solution after filtration; The solution was refluxed at 55°C for 6 hours to form a yellow sol; age the yellow sol at room temperature to obtain a yellow solid as a precursor; take 0.8g of the precursor and add 54ml of deionized water to dissolve and prepare a solution, and then add 5mol / l dropwise Hydrochloric acid solution to adjust the pH value to about 2, then add 1 g of polyethylene glycol with a molecular weight of 2000 and mix evenly to obtain a precursor solution; move the obtained precursor solution into a reaction kettle, react at 180°C for 20 hours, and cool naturally to room temperature. The obtained product was vacuum filtered, washed three times with ethanol and distilled water, and then dried in an oven at...

Embodiment 2

[0031] Slowly add 13g of tungsten powder into the mixed solution of 80ml of hydrogen peroxide and 8ml of deionized water, stir continuously in an ice-water bath until the tungsten powder is completely dissolved, and obtain a bright yellow peroxypolytungstic acid solution after filtration; The solution was refluxed at 50°C for 10 hours to form a yellow sol; age the yellow sol at room temperature to obtain a yellow solid as a precursor; take 0.8g of the precursor and add 54ml of deionized water to dissolve and prepare a solution, and then add 1mol / l dropwise The hydrochloric acid solution adjusted the pH value to about 1.5, then added 1 g of polyethylene glycol with a molecular weight of 20,000 and mixed evenly to obtain a precursor solution; moved the obtained precursor solution into a reaction kettle, reacted at 150°C for 24 hours, and cooled naturally to room temperature. The obtained product was vacuum filtered, washed with ethanol and distilled water for 5 times, and then dr...

Embodiment 3

[0033] Slowly add 13g of tungsten powder into the mixed solution of 80ml of hydrogen peroxide and 8ml of deionized water, stir continuously in an ice-water bath until the tungsten powder is completely dissolved, and obtain a bright yellow peroxypolytungstic acid solution after filtration; The solution was refluxed at 60°C for 5 hours to form a yellow sol; age the yellow sol at room temperature to obtain a yellow solid as a precursor; take 0.8g of the precursor and add 54ml of deionized water to dissolve and prepare a solution, and then add 3mol / l dropwise Hydrochloric acid solution to adjust the pH value to about 1.7, then add 1 g of polyethylene glycol with a molecular weight of 5000 and mix evenly to obtain a precursor solution; move the obtained precursor solution into a reaction kettle, react at 160°C for 22 hours, and cool naturally to room temperature. The obtained product was vacuum filtered, washed with ethanol and distilled water 4 times, and dried in an oven at 100°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com