Preparation method for positive electrode active material, and positive electrode active material

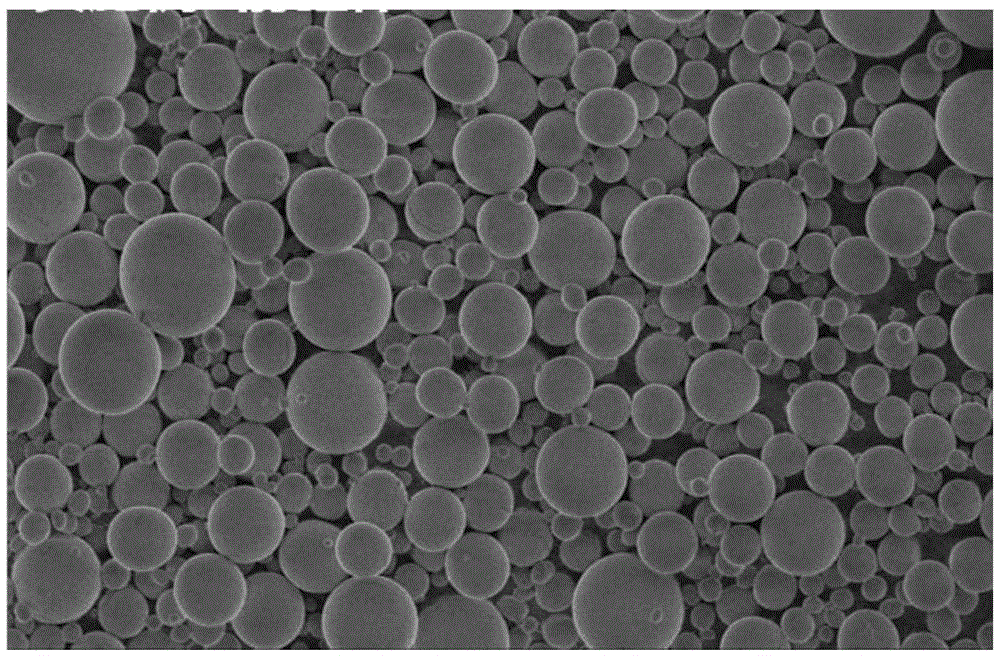

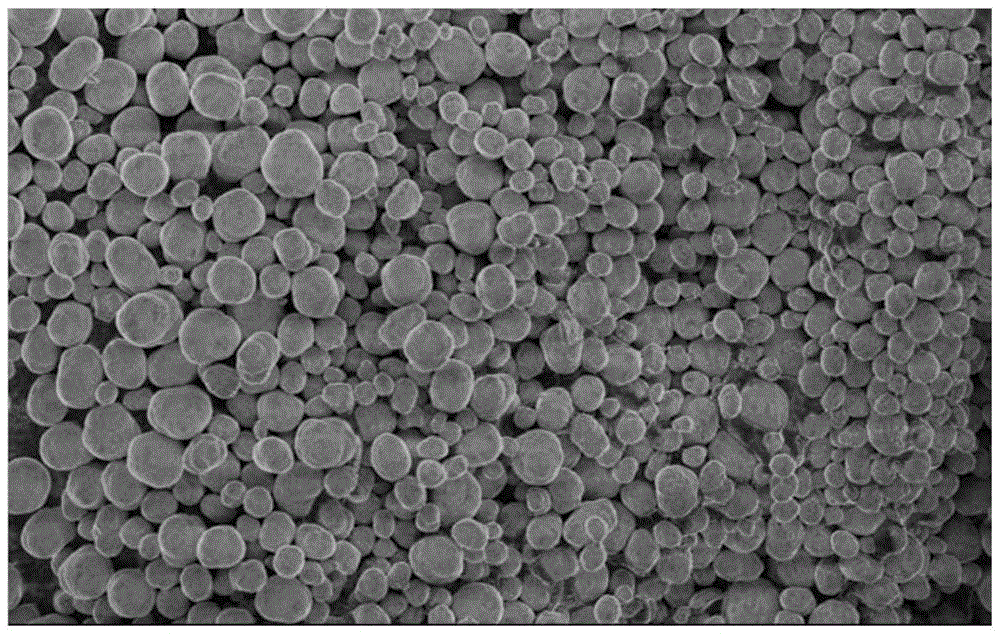

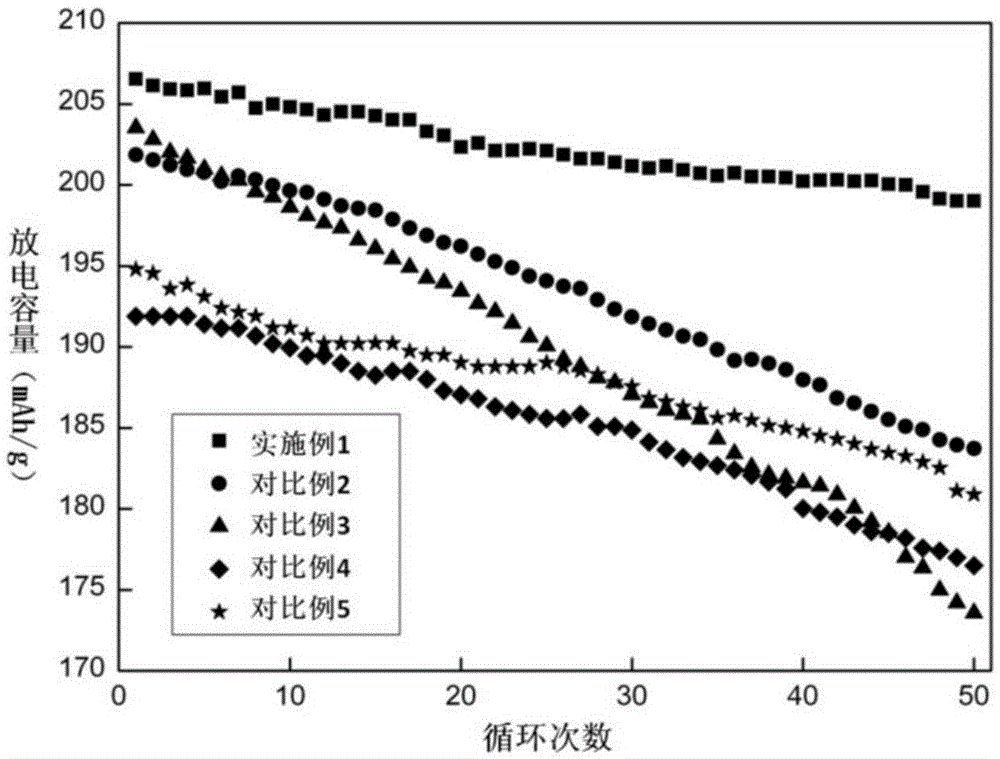

A cathode active material and seed crystal technology, which is applied to the preparation of cathode active materials and the field of cathode active materials, can solve the problems of easily irregular morphology, difficult uniform distribution of metal elements, poor crystallization performance of quaternary precursors, etc. Stable, high sphericity, regular shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of composite graphite provided by the invention comprises the steps:

[0028] S1. Mix the reaction seed crystal and complexing agent solution to form a reaction solution; the reaction seed crystal is one or more hydroxides of nickel, cobalt, manganese or aluminum; the D50 of the reaction seed crystal is ≤ 2 -6μm;

[0029] S2. Under stirring and ultrasonic conditions, adding a metal salt solution and a precipitating agent solution to the reaction solution, adjusting the pH to 9-13 for reaction; then washing and drying to obtain a precursor;

[0030] The metal salt solution is a solution containing nickel salt, cobalt salt, manganese salt and aluminum salt;

[0031] S3. Mix the precursor with the lithium source, then keep the temperature at 500-950° C. for 2-24 hours, and obtain the positive electrode active material after cooling.

[0032] The above-mentioned reaction seed crystal is used as the inner core, and various metals are precipitated and...

Embodiment 1

[0059] This example is used to illustrate the preparation method of the cathode active material disclosed in the present invention.

[0060] (1) prepare salt solution, be 81.5:10:5:3.5 ratio by the mol ratio of metal element nickel, cobalt, manganese, aluminum, nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate are dissolved in pure water, be mixed with A metal salt solution with a total metal content of 2mol / L;

[0061] (2) Take a certain amount of sodium hydroxide and be dissolved in pure water, be mixed with the precipitant alkali solution that concentration is 4mol / L, stand-by; Preparation concentration is the complexing agent ammonia solution of 5.0mol / L, stand-by;

[0062](3) Open the co-precipitation reactor, adjust the reaction temperature to be 60°C, and the stirring speed to be 600r / min, and add a certain amount of D50 to the reactor to be 3.5 μm quaternary precursor reaction crystal (quaternary precursor of nickel, cobalt, manganese and aluminum)...

Embodiment 2

[0069] This example is used to illustrate the preparation method of the cathode active material disclosed in the present invention.

[0070] (1) To prepare salt solution, the molar ratio of metal elements nickel, cobalt, manganese and aluminum is 80:10:5:5, and nickel sulfate, cobalt sulfate, manganese sulfate and aluminum sulfate are dissolved in pure water to prepare A metal salt solution with a total metal content of 2mol / L;

[0071] (2) Take a certain amount of sodium hydroxide and be dissolved in pure water, be mixed with the precipitant alkali solution that concentration is 4mol / L, stand-by; Preparation concentration is the complexing agent ammonia solution of 5.0mol / L, stand-by;

[0072] (3) Open the reaction kettle, adjust the reaction temperature to be 60°C, and the stirring speed is 600r / min, and add a certain amount of D50 to the reaction kettle, which is a quaternary precursor reaction seed crystal of 5 μm (quaternary hydroxide of nickel, cobalt, manganese and alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com