Method for preparing lithium ionic cell cathode material spinelle lithium titanate

A lithium-ion battery, lithium halite titanate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of complex process, high cost, high temperature, high energy consumption, etc., and achieve cheap and easy raw materials, high yield High and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

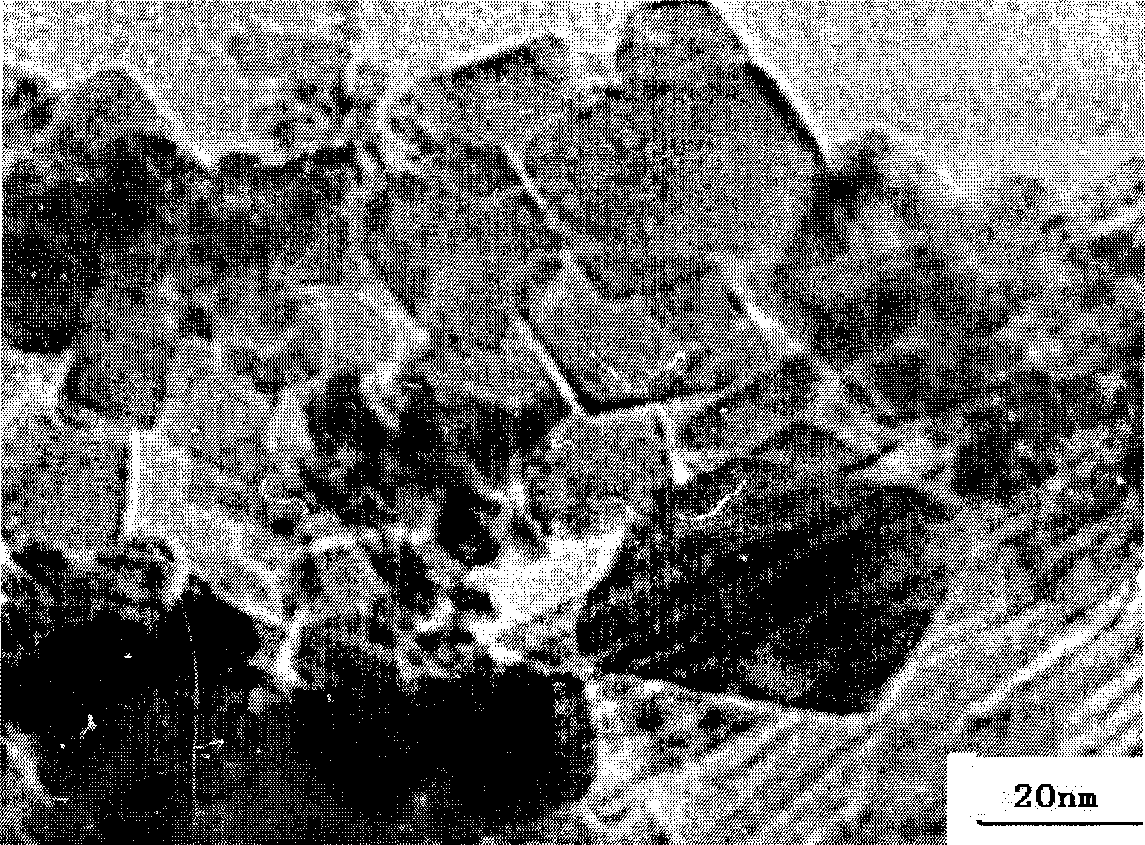

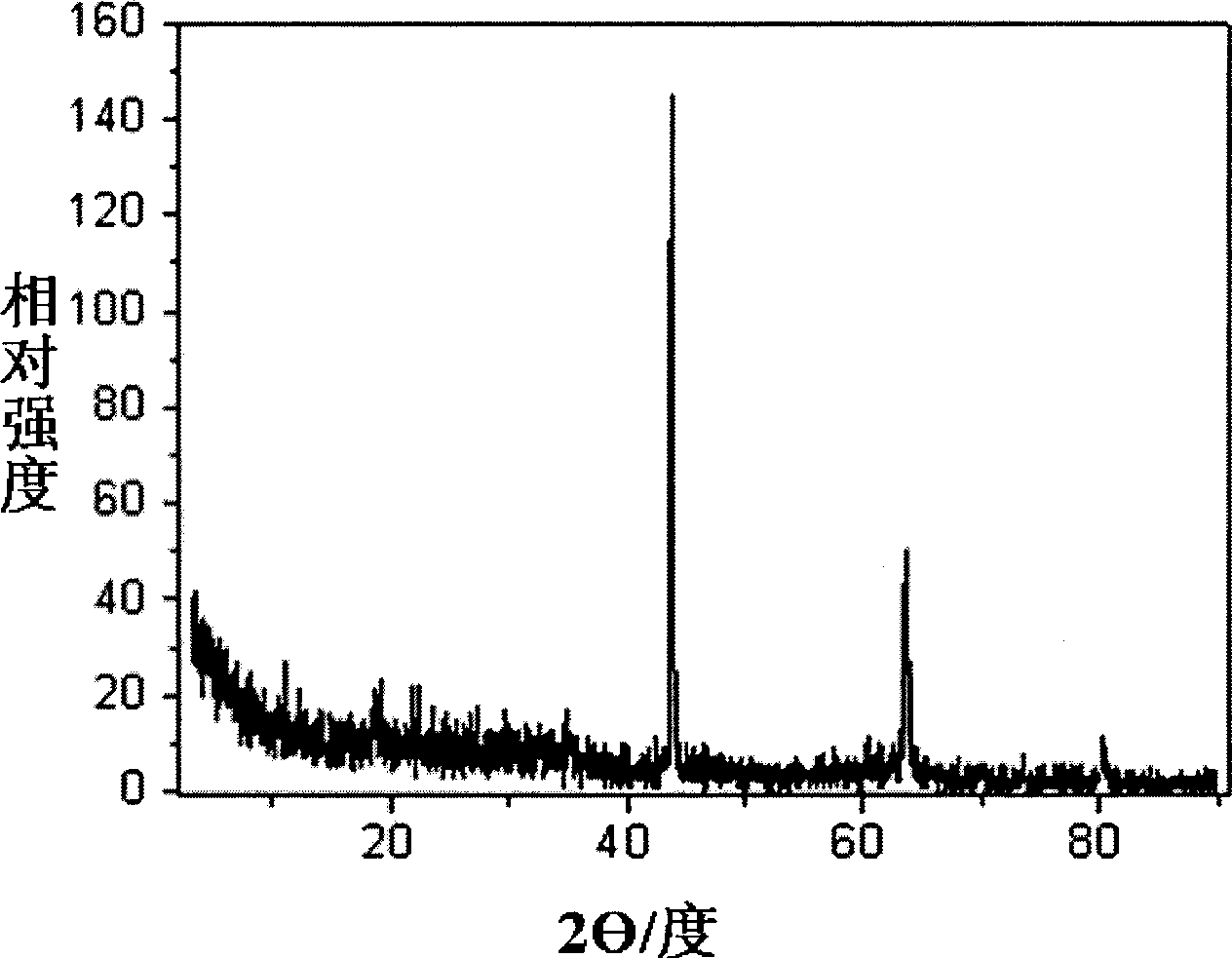

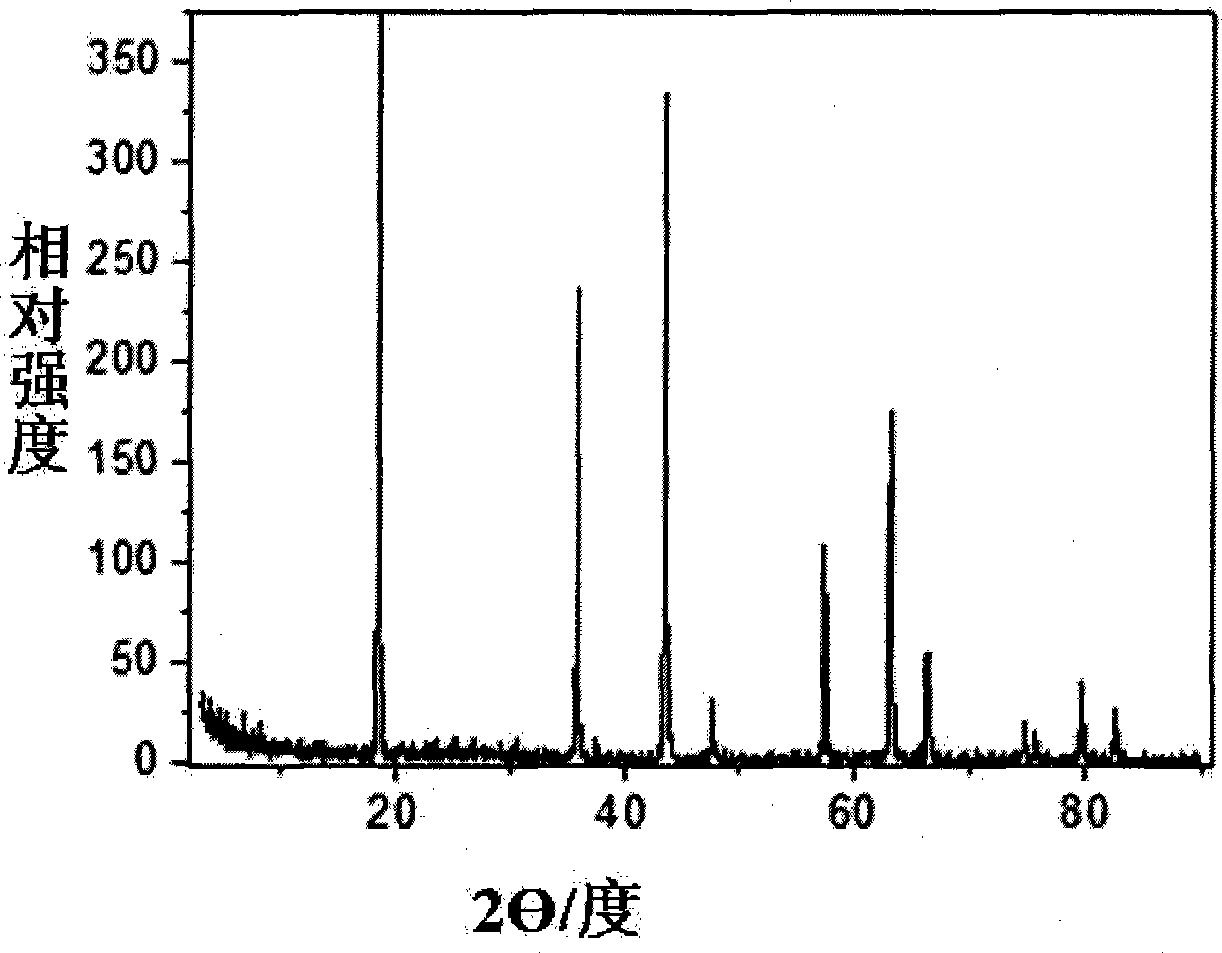

[0030] Weigh 5g of TiO 2 The powder was gradually added to 300ml of LiOH aqueous solution with a concentration of 10mol / L under the condition of uniform stirring, and after being uniformly dispersed, the temperature was gradually raised to 150°C, and the reaction was carried out at constant temperature for 24 hours under constant stirring. Then stop heating, and cool down to room temperature naturally. The sample was taken out, filtered, repeatedly washed with water until pH = 7.5, and dried to obtain lithium titanyl oxide precursor powder. The prepared precursor powder was calcined at 700 °C for 6 h to obtain the product Li 4 Ti 5 o 12 .

Embodiment 2

[0032] Weigh 5g of metatitanic acid powder, gradually add 300ml of LiOH aqueous solution with a concentration of 10mol / L under the condition of uniform stirring, gradually raise the temperature to 120°C after uniform stirring, and react at constant temperature for 12h under the condition of constant stirring. Then stop heating, and cool down to room temperature naturally. The sample was taken out, filtered, repeatedly washed with water until pH = 7.5, and dried to obtain lithium titanyl oxide precursor powder. The prepared precursor powder was calcined at 700 °C for 6 h to obtain the product Li 4 Ti 5 o 12 .

Embodiment 3

[0034] Weigh 10g of metatitanic acid powder, gradually add 300ml of LiOH aqueous solution with a concentration of 5mol / L under the condition of uniform stirring, gradually raise the temperature to 80°C after uniform dispersion, and react at constant temperature for 24 hours under constant stirring. Then stop heating, and cool down to room temperature naturally. The sample was taken out, filtered, repeatedly washed with water until pH = 7.5, and dried to obtain lithium titanyl oxide precursor powder. The prepared precursor powder was calcined at 700 °C for 3 h to obtain the product Li 4 Ti 5 o 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com