Spherical cerium dioxide

A ceria, spherical technology, applied in the field of micro-nano material synthesis, can solve the problems of long reaction time, high temperature specific surface drop, poor crystallinity, etc. Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

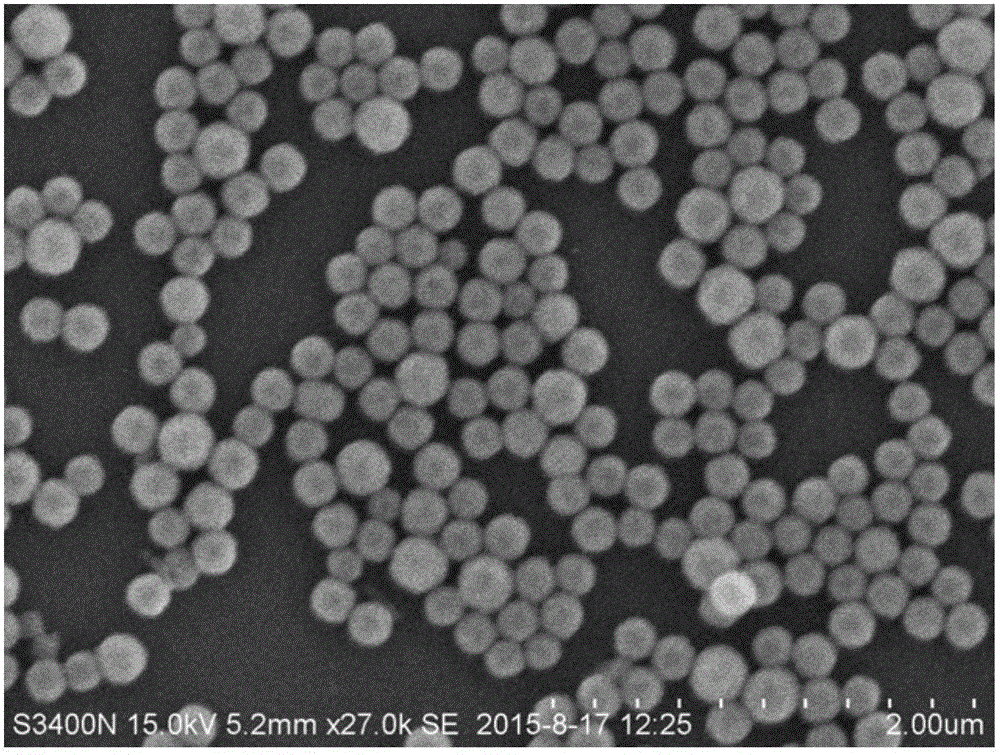

Embodiment 1

[0043] A kind of spherical cerium oxide is prepared, which has the following steps:

[0044] (1) Weigh CeCl 3 ·7H 2 O was dissolved in deionized water and ethylene glycol, stirred until it was completely dissolved, then polyvinylpyrrolidone (PVP, molecular weight M=58000) was added, and stirred for about 1 hour to obtain a transparent and clear solution, which was obtained by adding glacial acetic acid and stirred for about 0.5 hours to obtain clear transparent liquid;

[0045] (2) Transfer the transparent and clear mixed solution into a 100ml polytetrafluoroethylene lining, put it into a stainless steel reaction kettle, and react at 180°C for 1h;

[0046] (3) After the reactor was cooled to room temperature, the product was centrifuged at a speed of 10000r / min for 5min to obtain a precipitate, which was washed alternately with deionized water and ethanol for 3 times, and then dried at 80°C for 12h to obtain ceria.

[0047] Test preparation:

[0048] (1) BET specific surfa...

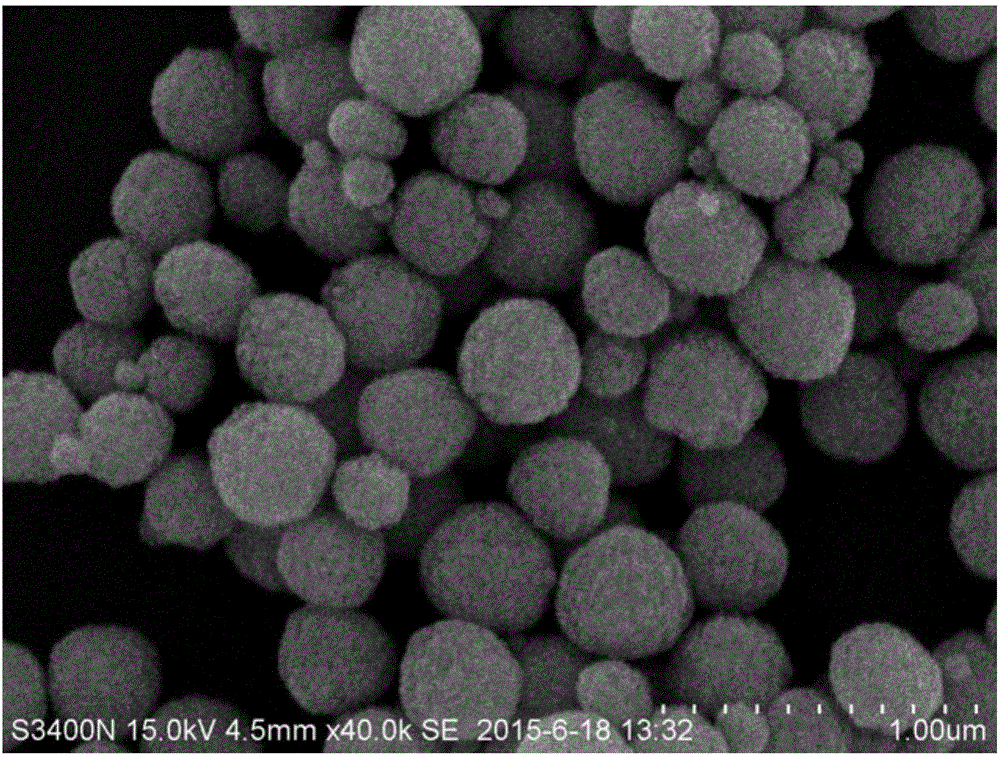

Embodiment 2

[0060] A kind of spherical cerium oxide is prepared, which has the following steps:

[0061] (1) Weigh CeCl 3 ·7H 2 Dissolve O in deionized water, stir until completely dissolved, then add polyvinylpyrrolidone (PVP, molecular weight M = 58000), stir for about 1 hour to obtain a transparent and clear solution, add glacial acetic acid, and finally add urea, stir for about 0.5 hours to obtain clarification transparent liquid;

[0062] (2) Transfer the transparent and clear mixed solution into a 100ml polytetrafluoroethylene lining, put it into a stainless steel reaction kettle, and react at 180°C for 1h;

[0063] (3) After the reactor was cooled to room temperature, the product was centrifuged at a speed of 10000r / min for 5min to obtain a precipitate, which was washed alternately with deionized water and ethanol for 3 times, and then dried at 80°C for 12h to obtain ceria.

[0064] Test preparation:

[0065] (1) BET specific surface area test: Dry the cerium oxide prepared in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com