Preparation method of tri-phosphor double-peak blue fluorescent powders for lamp

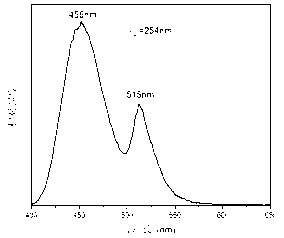

A technology of blue phosphor and three primary colors is applied in the field of preparation of bimodal blue phosphor to achieve the effects of good thermal stability, uniform powder particles and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

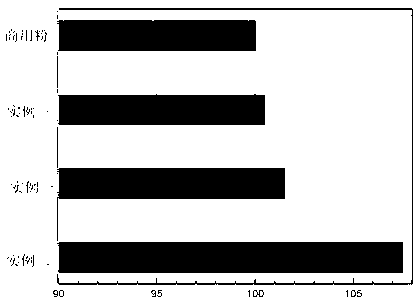

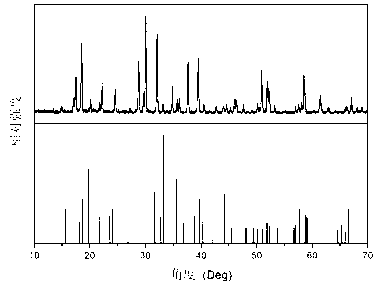

Examples

Embodiment 1

[0024] According to Ba 1-x MgAl 10 o 17 :(Eu 2+ , Mn 2+ ) Stoichiometric ratio Weigh 3.735g α-Al raw materials respectively 2 o 3 , 0.275gMgO, 0.855gBaCO 3 , 0.12gEu 2 o 3 , 0.015gMnCO 3 , 0.025gCaF 2 , 0.300gBaF 2 (All the above raw materials are analytically pure), put all the raw materials into a ball mill and add an appropriate amount of alcohol to ball mill for 1 hour; put the mixed raw materials into a corundum crucible under H 2 / N 2 (5 / 95%) atmosphere at 1350-1500°C for 4 hours, cooled to room temperature to obtain the final calcined product; the final calcined product was ground, washed, filtered, dried and sieved to obtain BAM blue phosphor. After calcining at 550° C. and 600° C. for half an hour in an air atmosphere, heat-treated BAM blue phosphor powder was obtained.

Embodiment 2

[0026] According to Ba 1-x MgAl 10 o 17 :(Eu 2+ , Mn 2+ ) stoichiometric ratio weighed 3.735gα-Al respectively 2 o 3 , 0.275gMgO, 0.855gBaCO 3 , 0.12gEu 2 o 3 , 0.015gMnCO 3 , 0.05gCaF 2 , 0.300gBaF 2 (All the above raw materials are analytically pure), put all the raw materials into a ball mill and add an appropriate amount of alcohol to ball mill for 1 hour; put the mixed raw materials into a corundum crucible for H 2 / N 2(5 / 95%) atmosphere at 1350-1500°C for 4 hours, cooled to room temperature to obtain the final calcined product; the final calcined product was ground, washed, filtered, dried, and sieved to obtain BAM blue phosphor. After calcining at 550° C. and 600° C. for half an hour in an air atmosphere, heat-treated BAM blue phosphor powder was obtained.

Embodiment 3

[0028] According to Ba 1-x MgAl 10 o 17 :(Eu 2+ , Mn 2+ ) stoichiometric ratio weighed 3.735gα-Al respectively 2 o 3 , 0.275gMgO, 0.855gBaCO 3 , 0.12gEu 2 o 3 , 0.015gMnCO 3 , 0.025gCaF 2 , 0.200gBaF 2 (All the above raw materials are analytically pure), put all the raw materials into a ball mill and add an appropriate amount of alcohol to ball mill for 1 hour; put the mixed raw materials into a corundum crucible for H 2 / N 2 (5 / 95%) atmosphere at 1350-1500°C for 4 hours, cooled to room temperature to obtain the final calcined product; the final calcined product was ground, washed, filtered, dried and sieved to obtain BAM blue phosphor. After calcining at 550° C. and 600° C. for half an hour in an air atmosphere, heat-treated BAM blue phosphor powder was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com