Method for preparing active material calcium zincate of cathode of battery by utilizing airflow mill

A battery negative electrode and active material technology, applied to battery electrodes, nickel storage batteries, alkaline storage batteries, etc., can solve the problems of low charge and discharge performance and cycle performance, long production time, low stability, etc., to avoid gas swelling , large production capacity and uniform fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

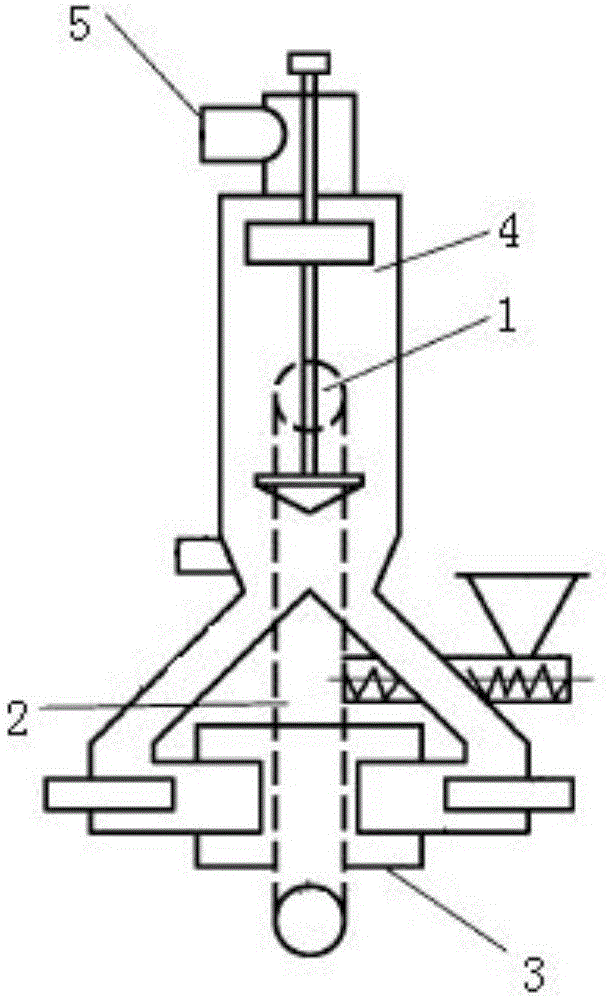

[0036] The method for preparing the battery negative electrode active material calcium zincate by jet mill of the present embodiment comprises the following steps:

[0037] Step 1: After mixing and stirring zinc oxide, calcium hydroxide and deionized water in a weight ratio of 4:4:1, the particle diameters of the zinc oxide and calcium hydroxide are both 50-150 mesh, and put them into the jet mill Material inlet 1, the pressure of the material inlet 1 is 0.4-0.8MPa, and then enters the crushing chamber 3 through the riser 2, the pressure of the crushing chamber 3 is 0.002-0.01MPa, and the crushed material is obtained;

[0038] Step 2: Enter the pulverized material obtained in Step 1 into the classification chamber 4 for classification, and the speed of the classification is 3000-6000 rpm to obtain the classified particles;

[0039] Step 3: The classified particles obtained in step 2 are returned to the crushing chamber (3) with a particle size of ≤1000 mesh for re-grinding; th...

Embodiment 2

[0041] The method for preparing the battery negative electrode active material calcium zincate by jet mill of the present embodiment comprises the following steps:

[0042] Step 1: After mixing and stirring zinc oxide, calcium hydroxide and deionized water in a weight ratio of 6:6:1, the particle diameters of the zinc oxide and calcium hydroxide are both 50-150 mesh, and put them into the jet mill Material inlet 1, the pressure of the material inlet 1 is 0.4-0.8MPa, and then enters the crushing chamber 3 through the riser 2, the pressure of the crushing chamber 3 is 0.002-0.01MPa, and the crushed material is obtained;

[0043] Step 2: Enter the pulverized material obtained in Step 1 into the classification chamber 4 for classification, and the speed of the classification is 3000-6000 rpm to obtain the classified particles;

[0044] Step 3: The classified particles obtained in step 2 are returned to the crushing chamber (3) with a particle size of ≤1000 mesh for re-grinding; th...

Embodiment 3

[0046] The method for preparing the battery negative electrode active material calcium zincate by jet mill of the present embodiment comprises the following steps:

[0047] Step 1: After mixing and stirring zinc oxide, calcium hydroxide and deionized water in a weight ratio of 5:5:1, the particle diameters of the zinc oxide and calcium hydroxide are both 50-150 mesh, and put them into the jet mill Material inlet 1, the pressure of the material inlet 1 is 0.4-0.8MPa, and then enters the crushing chamber 3 through the riser 2, the pressure of the crushing chamber 3 is 0.002-0.01MPa, and the crushed material is obtained;

[0048] Step 2: Enter the pulverized material obtained in Step 1 into the classification chamber 4 for classification, and the speed of the classification is 3000-6000 rpm to obtain the classified particles;

[0049] Step 3: The classified particles obtained in step 2 are returned to the crushing chamber (3) with a particle size of ≤1000 mesh for re-grinding; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com