Method for preparing polycrystalline silicon particles from silicon wastes

A polysilicon and silicon waste technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of high possibility of pollution, waste of resources, and shortened life of equipment, so as to ensure the quality and efficiency of sintering and facilitate storage and transportation, to ensure the full effect of sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

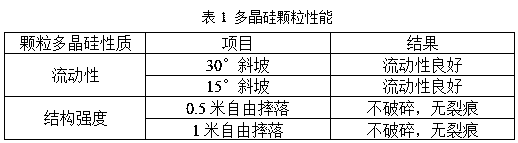

Examples

Embodiment 1

[0047] A method for preparing polysilicon particles from silicon waste, comprising the steps of:

[0048] A. cleaning the collected silicon waste;

[0049] B. Stir the cleaned silicon waste in a mixer until it is evenly mixed to obtain a blend;

[0050] C. placing the mixed material treated in step B in a granulator, and granulating to obtain material granules; then, drying, controlling the moisture content to <0.01%, to obtain dry material granules;

[0051] D. Place the dried material particles obtained in step C in a microwave sintering furnace, and sinter under the protection of a gas atmosphere to obtain the primary product of polysilicon particles;

[0052] F. The primary product of polysilicon particles obtained in step D is cooled to below 80° C. in a protective atmosphere with a temperature lower than 100° C., and the finished polysilicon particles are obtained.

Embodiment 2

[0054] A method for preparing polysilicon particles from silicon waste, comprising the steps of:

[0055] A. Clean the collected reduction furnace silicon powder, fluidized bed silicon powder and cutting silicon powder to remove the pollutants attached to the surface of the silicon waste; wherein, the cleaning includes the first cleaning and the second cleaning, the first cleaning is acid cleaning; the second Cleaning is ultrapure water cleaning first, and then ultrasonic cleaning;

[0056] B. Stir the cleaned silicon waste in a mixer until it is evenly mixed to obtain a blend;

[0057] C. Put the mixed material processed in step B in an extrusion granulator, and granulate under the conditions of temperature 50°C and pressure 9.8 tons to obtain material granules with a particle size of 300 μm to 30 mm; then, hot air drying, controlled Moisture content < 0.01%, to obtain dry material particles;

[0058] D. Put the dry material particles obtained in step C in a microwave s...

Embodiment 3

[0063] A method for preparing polysilicon particles from silicon waste, comprising the steps of:

[0064] A. Collect silicon powder from reduction furnace and fluidized bed silicon powder (control the collection process from pollution, avoid the cleaning process, effectively shorten the preparation cycle, and effectively save resources, etc.);

[0065] B. Stir the cleaned silicon waste in a mixer until it is evenly mixed, and the mixing time is 20 minutes to obtain a mixed material;

[0066] C. Put the mixed material processed in step B in a kneading granulator, and granulate it at a temperature of 45°C and a pressure of 10.2 tons to obtain material particles with a particle size of 300 μm to 30 mm; then, microwave drying to control the water content The rate is less than 0.01%, and the dry material particles are obtained;

[0067] D. Put the dry material particles obtained in step C in a microwave sintering furnace, under the protection of nitrogen gas atmosphere, and si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com