a nanobi 2 ti 2 o 7 Powder preparation method

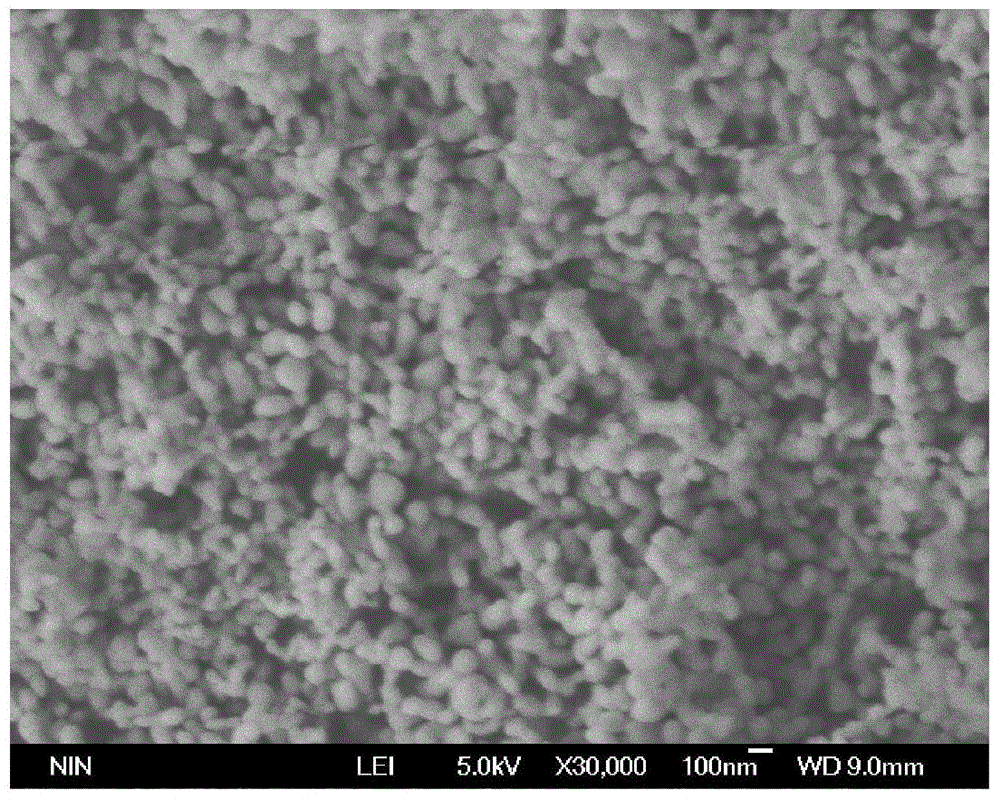

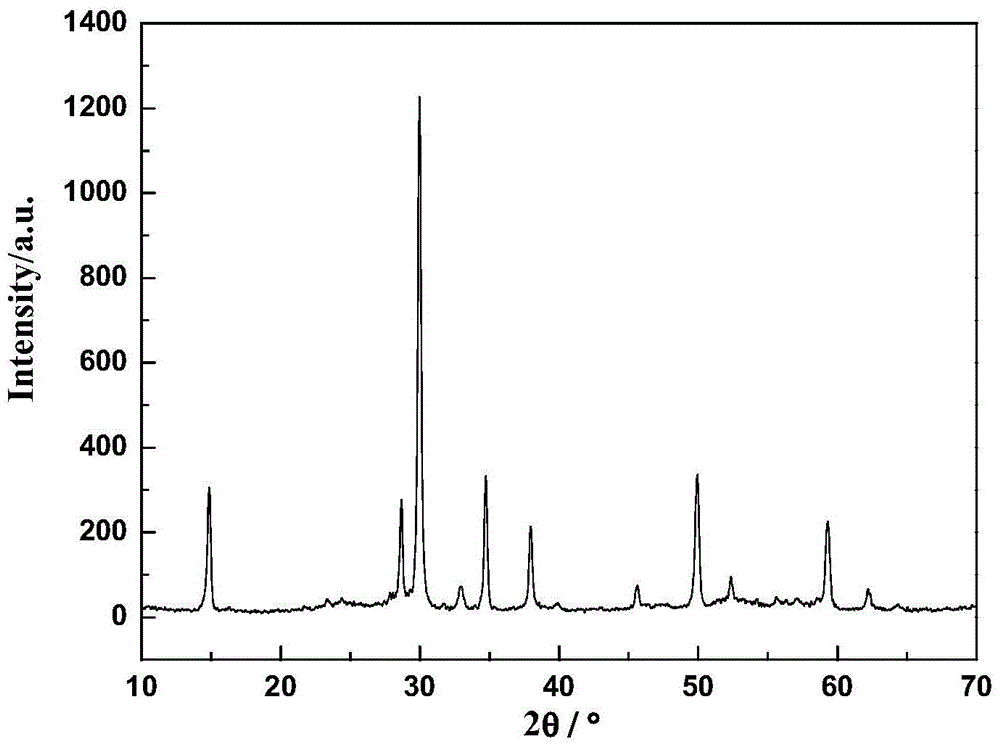

A powder and nano technology, applied in the field of preparation of nano Bi2Ti2O7 powder, can solve the problems of long time required for hydrothermal synthesis, easy to produce agglomeration, low yield, etc., and achieve improved photocatalytic performance, regular particle morphology, fully developed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] step one:

[0025] Weigh 0.005mol of Bi(NO 3 ) 3 ·5H 2 O was placed in a dry beaker, 10ml of acetic anhydride was added to it, and it was allowed to stand for 4 hours to make Bi(NO 3 ) 3 ·5H 2 O is completely dissolved, and the solution concentration is 0.5mol / L; this solution is recorded as A;

[0026] Step two:

[0027] Weigh 0.005 mol of tetrabutyl titanate and dissolve it in 17 ml of ethylene glycol to a solution concentration of 0.3 mol / L, and add glacial acetic acid dropwise to the solution to make the pH of the solution 5; this solution is denoted as B;

[0028] Step three:

[0029] Add solution A to solution B, mix and stir for 5 hours to obtain a precursor solution;

[0030] Step four:

[0031] Put the precursor solution in step 3 into an oven, set the oven temperature to 80°C, get a white gel after 5 hours, and get a dry precursor powder after continuing to dry for 24 hours;

[0032] Step five:

[0033] Calcinate the precursor powder in step 4, rais...

Embodiment 2

[0035] step one:

[0036] Weigh 0.005mol of Bi(NO 3 ) 3 ·5H 2 O was placed in a dry beaker, 5ml of acetic anhydride was added to it, and it was allowed to stand for 4 hours to make Bi(NO 3 ) 3 ·5H 2 O is completely dissolved, and the solution concentration is 1.0mol / L; this solution is recorded as A;

[0037] Step two:

[0038] Weigh 0.005 mol of tetrabutyl titanate and dissolve it in 50 ml of ethylene glycol to a solution concentration of 0.1 mol / L, and add glacial acetic acid dropwise to the solution to make the pH of the solution 5; this solution is denoted as B;

[0039] Step three:

[0040] Add solution A to solution B, mix and stir for 8 hours to obtain a precursor solution;

[0041] Step four:

[0042] Put the precursor solution in step 3 into an oven, set the oven temperature to 80°C, get a white gel after 5 hours, and get a dry precursor powder after continuing to dry for 24 hours;

[0043] Step five:

[0044] Calcinate the precursor powder in step 4, raise...

Embodiment 3

[0046] step one:

[0047] Weigh 0.004mol of Bi(NO 3 ) 3 ·5H 2 O was placed in a dry beaker, 5ml of acetic anhydride was added to it, and it was allowed to stand for 4 hours to make Bi(NO 3 ) 3 ·5H 2 O is completely dissolved, and the solution concentration is 0.8mol / L; this solution is recorded as A;

[0048] Step two:

[0049]Weigh 0.004mol of tetrabutyl titanate and dissolve it in 15ml of ethylene glycol to a solution concentration of 0.27mol / L, and add glacial acetic acid dropwise to the solution to make the pH of the solution 5; this solution is denoted as B;

[0050] Step three:

[0051] Add solution A to solution B, mix and stir for 6 hours to obtain a precursor solution;

[0052] Step four:

[0053] Put the precursor solution in step 3 into an oven, set the oven temperature to 80°C, get a white gel after 5 hours, and get a dry precursor powder after continuing to dry for 24 hours;

[0054] Step five:

[0055] Calcinate the precursor powder in step 4, raise th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com