Preparation method for increasing weather fastness of titanium dioxide

A titanium dioxide and weather resistance technology, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of silicon film layer or titanium dioxide bare leakage, unable to form dense film, aluminum film is not very dense and so on , to achieve the effect of excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

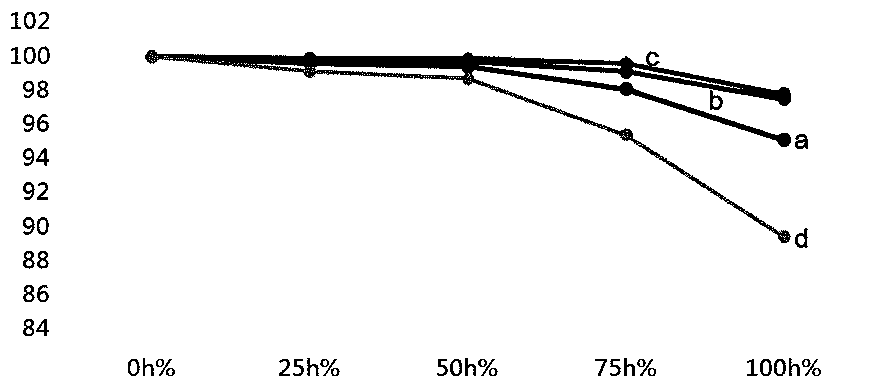

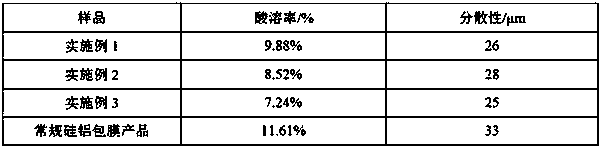

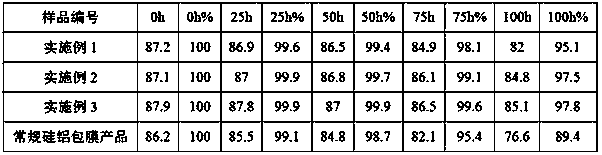

Examples

Embodiment 1

[0032] Sand mill the kiln products of qualified calcined titanium dioxide, and then import the slurry with qualified particle size into the coating tank, and control the concentration of the slurry to 200g / L (based on TiO 2 At the same time, the temperature was raised to 85°C; NaOH was added to the slurry to adjust the pH=10.0, the addition was completed in 15 minutes, and homogenized for 30 minutes; 1.0% Na was added 2 SiO 3 , used for 20min, then homogenized for 20min; use dilute H 2 SO 4 Adjust pH = 7.0, take 120min, then homogenize for 30min; use dilute H 2 SO 4 Adjust pH=4.5, take 20 minutes, then homogenize for 20 minutes; add 1.0% Al at the same time 2 (SO4) 3 (in Al 2 o 3 flow together with NaOH, keep pH=4.5 for 60 minutes, and then homogenize for 30 minutes; import the obtained slurry into a sand mill and grind for 20 minutes; adjust the pH of the slurry to 8.0 with NaOH for 20 minutes, and then homogenize 30min; add 3.0%NaAlO at the same time 2 (in Al 2 o ...

Embodiment 2

[0034] Sand mill the kiln products of qualified calcined titanium dioxide, and then import the slurry with qualified particle size into the coating tank, and control the concentration of the slurry to 300g / L (based on TiO 2 At the same time, the temperature was raised to 85°C; NaOH was added to the slurry to adjust the pH=10.2, the addition was completed in 15 minutes, and homogenized for 30 minutes; 3.0% Na was added 2 SiO 3 , take 20min, then homogenize for 20min; use dilute HCl to adjust pH=7.2, take 120min, then homogenize for 30min; use dilute HCl to adjust pH=4.8, take 30min, then homogenize for 120min; 2 (SO 4 ) 3 (in Al 2 o 3 (meter) and NaOH in parallel flow, keep pH=4.8 for 60 minutes, then homogenize for 30 minutes; import the obtained slurry into a sand mill, and sand for 20 minutes; adjust the pH of the slurry to 8.5 with NaOH, take 20 minutes, and then homogenize 30min; add 2.0%NaAlO at the same time 2 (in Al 2 o 3) and dilute HCl in parallel flow, keep p...

Embodiment 3

[0036] Sand mill the kiln products of qualified calcined titanium dioxide, and then import the slurry with qualified particle size into the coating tank, and control the concentration of the slurry to 400g / L (based on TiO 2 At the same time, the temperature was raised to 85°C; KOH was added to the slurry to adjust the pH=10.5, the addition was completed in 15 minutes, and homogenized for 30 minutes; 6.0% Na was added 2 SiO 3 , used for 20min, then homogenized for 20min; use dilute H 2 SO 4 Adjust the pH to 7.5 for 120 minutes, then homogenize for 30 minutes; use dilute H 2 SO 4 Adjust pH=5.5, take 30 minutes, then homogenize for 120 minutes; add 3.0% Al at the same time 2 (SO 4 ) 3 (in Al 2 o 3 meter) and KOH in parallel flow, keep pH=5.5 for 60 minutes, and then homogenize for 30 minutes; import the obtained slurry into a sand mill and grind for 20 minutes; adjust the pH of the slurry to 9.0 with dilute KOH for 30 minutes, and then Homogenize for 30min; add 1.0%NaAlO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com