High-molecular mPEG-PLGA-mPEG accessory medicine for medicine use, prepu. method and application thereof

A technology of polymers and excipients, applied in the field of amphiphilic tri-block copolymers, can solve the problems of difficult acquisition of synthetic raw materials and harsh conditions for the synthesis of choline phospholipids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

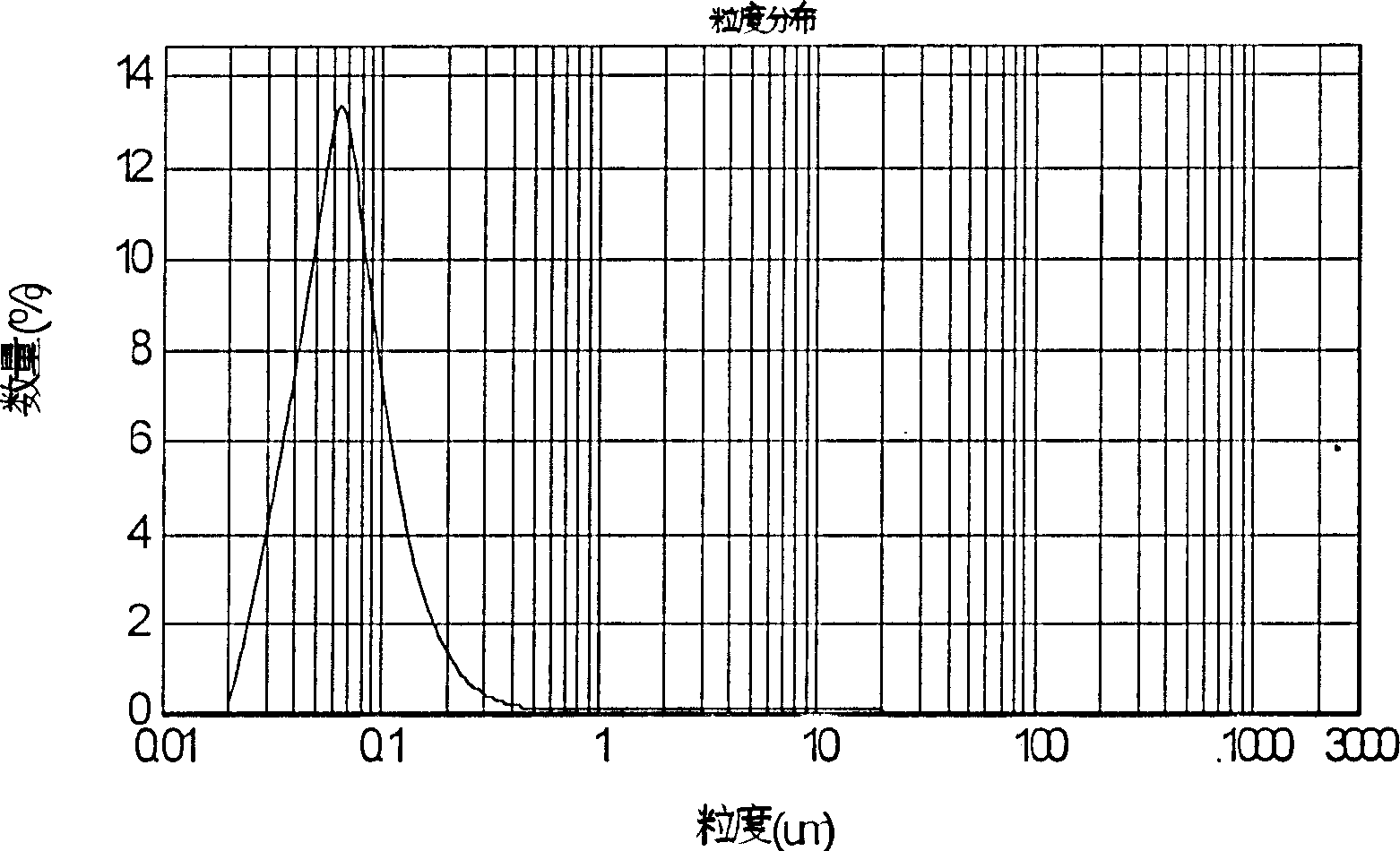

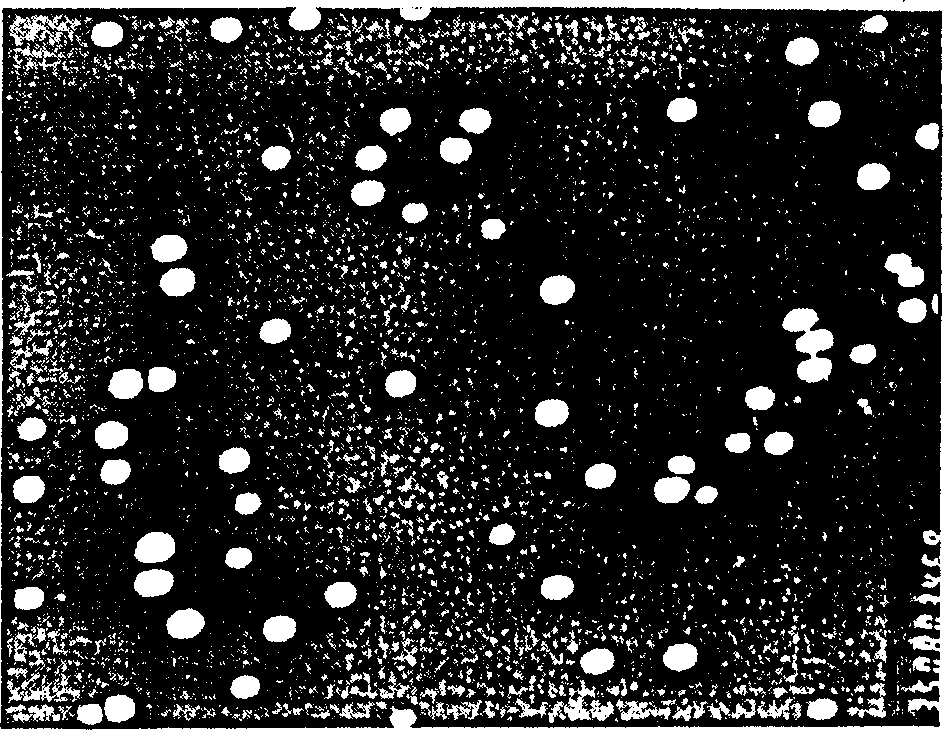

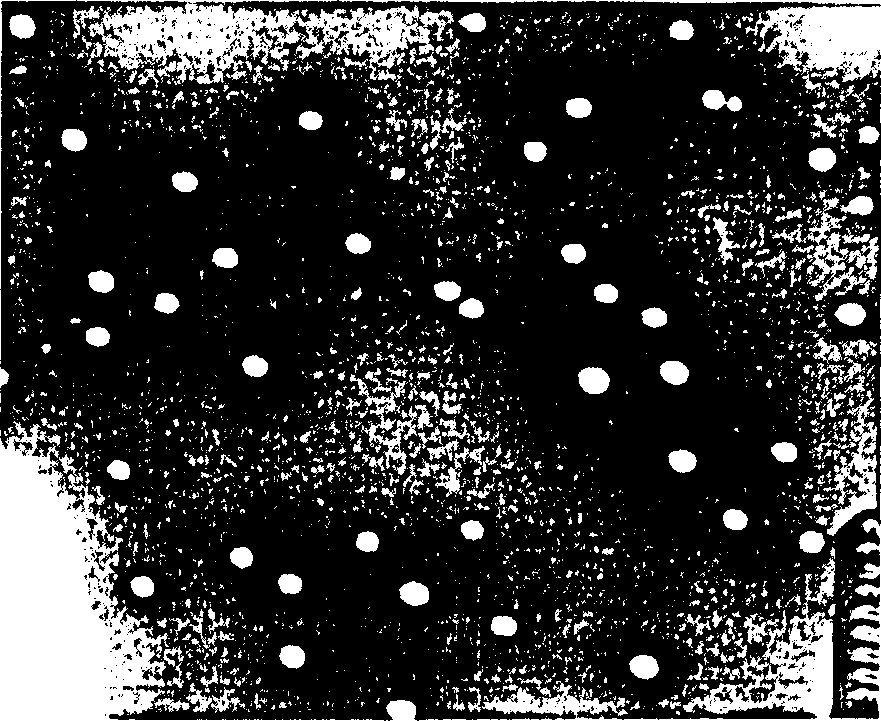

Image

Examples

Embodiment 1

[0028] Get lactide (LA), glycolide (GA) with a molar ratio of 4:1 and 10% polyethylene glycol (mPEG) accounting for the total weight and mix them in a sealed container, add 0.05% stannous octoate Catalyst, sealed tube under vacuum. After reacting at 150°C for 8 hours, the sealed tube was opened to dissolve the product, filtered and slowly added dropwise to methanol for precipitation under stirring conditions, and the precipitated product was vacuum-dried at room temperature to constant weight to obtain the PELGA material. Take a certain amount of prepared PELGA and place it in a two-neck bottle, add a certain amount of toluene, after the material is dissolved, slowly add 10% diisocyanate dropwise, slowly raise the temperature to 80°C and react for 12 hours, then raise the temperature to 115°C to reflux After 6 hours, after the toluene was dried by rotary evaporation, the dissolved product was slowly added dropwise to methanol for precipitation under stirring conditions, and th...

Embodiment 2

[0030]Take a certain amount of poly(lactic-co-glycolic acid) (PLGA) (where LA:GA is 70:30) mixed with polyethylene glycol and placed in a fusion-sealed container, add 0.03% stannous octoate, and seal in a vacuum state. Tube. After reacting at 160°C for 10 hours, the sealed tube was opened to dissolve the product, filtered and slowly added dropwise to excess ether to precipitate under stirring conditions, and the precipitated product was vacuum-dried at room temperature to constant weight to obtain the PELGA material. Take a certain amount of prepared PELGA and place it in a two-necked bottle, add a certain amount of toluene, after the material is dissolved, slowly add 7% diisocyanate, slowly raise the temperature to 70°C and react for 10 hours, then heat up to 110°C and reflux for 10 hours hours, after rotary evaporation to dry the toluene, dissolve the product, and slowly add it dropwise to 10-30 parts of diethyl ether to precipitate under stirring conditions, and vacuum-dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com