High-performance lithium ion battery composite positive electrode material and preparation method thereof

A composite cathode material, lithium-ion battery technology, applied in battery electrodes, active material electrodes, positive electrodes, etc., can solve rare problems, achieve regular particle morphology, inhibit phase transition, and reduce harmful phase transition effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

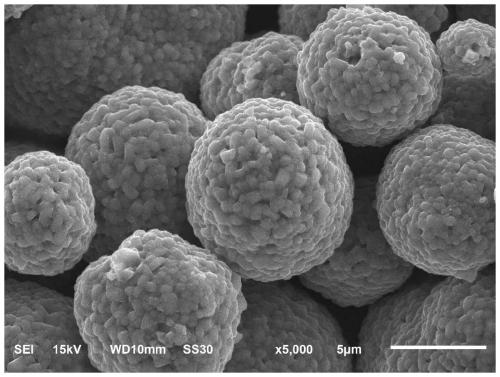

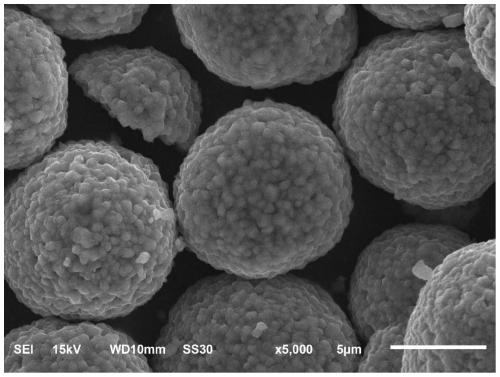

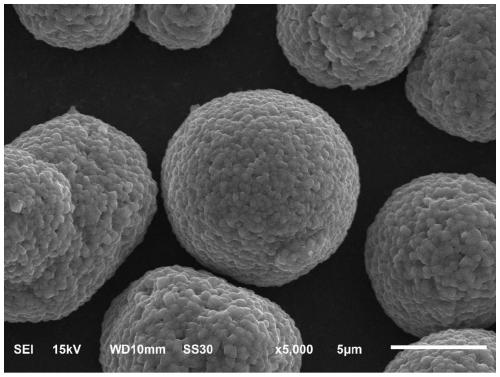

Image

Examples

preparation example Construction

[0055] The present invention also provides a method for preparing the above-mentioned high-performance lithium-ion battery composite positive electrode material, which specifically includes the following steps:

[0056] Scheme 1: When a=0, namely Bi 2-a m a WO 6 The cladding layer is specifically Bi 2 WO 6 Covering layer, the preparation method of described high-performance lithium-ion battery composite cathode material is as follows:

[0057] (1) Weigh soluble tungstate and soluble salts containing bismuth source according to the ratio of 2:1 molar ratio of Bi and W elements and dissolve them in solvent, adjust the pH to 9-10, under mechanical stirring or ultrasonic treatment Fully react for 10-30 minutes to generate Bi 2 WO 6 ; Stirring speed and ultrasonic intensity are generally adjusted according to the amount of material to be treated, for example: mechanical stirring speed is 300-1500 rpm.

Embodiment 1

[0081] Example 1: 1 wt% Bi 2 WO 6 Modified lithium ion battery LiNi 0.5 co 0.2 mn 0.3 o 2 Cathode material

[0082] Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 Dissolve 1.39g and 0.47g each of O in 100mL deionized water, adjust the pH in the range of 9 to 10, stir magnetically for 30min, and add 100g of LiNi prepared by referring to the method of Comparative Example 1 after the reaction is uniform. 0.5 co 0.2 mn 0.3 o 2 The positive electrode material is then stirred at 80°C for 4h, cooled at room temperature, filtered, washed with deionized water, dried, and calcined at 800°C for 6h in an oxygen atmosphere to obtain 1wt% Bi 2 WO 6 Modified lithium ion battery LiNi 0.8 co 0.1 mn 0.1 o 2 Composite cathode material, denoted as A1.

Embodiment 2

[0083] Example 2: 1 wt% Bi 2 WO 6 Modified lithium ion battery LiNi 0.6 co 0.2 mn 0.2 o 2 Cathode material

[0084] Bi(NO 3 ) 3 ·5H 2 O and Na 2 WO 4 2H 2 Dissolve 1.39g and 0.47g of each in 100mL deionized water, adjust the pH in the range of 9 to 10, stir magnetically for 30min, and add 100g of LiNi prepared by referring to the method of Comparative Example 2 after the reaction is uniform. 0.6 co 0.2 mn 0.2 o 2 The positive electrode material was then stirred at 80°C for 4h, cooled at room temperature, filtered, washed with deionized water, dried, and calcined at 700°C for 6h in an oxygen atmosphere to obtain 1wt% Bi 2 WO 6 Modified lithium ion battery LiNi 0.6 co 0.2 mn 0.2 o 2 Composite cathode material, denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com