Fine developer for large format development and preparation method thereof

A developer and large-format technology, applied in the field of fine developer for large-format development and its preparation, can solve the problems of poor uniformity of charge distribution, irregular shape, environmental impact, etc., and achieve uniform distribution of particle size/electrical properties and stable charging , the effect of particle rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

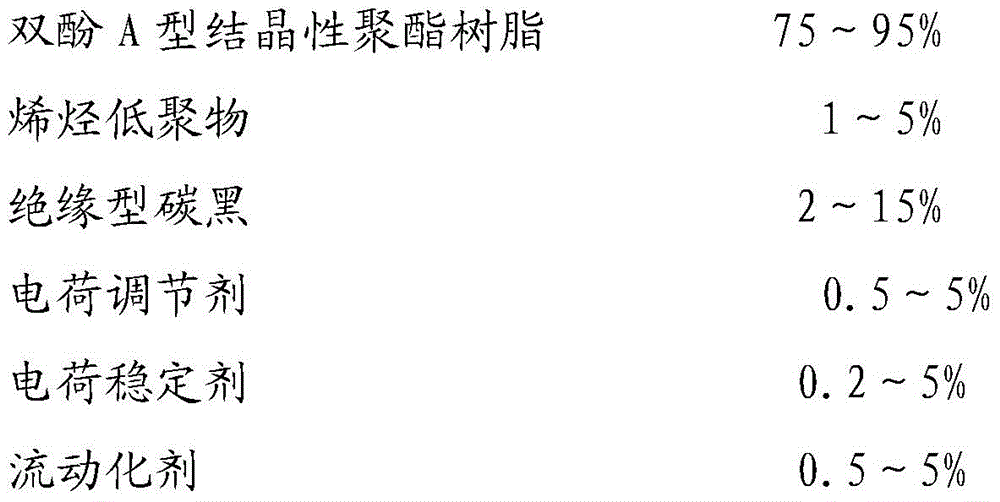

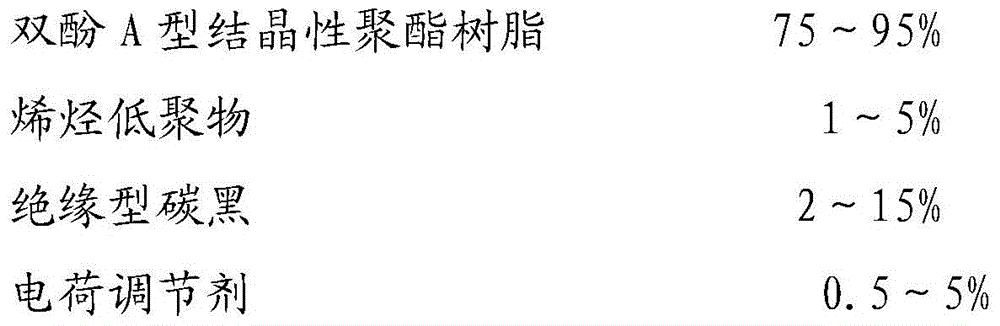

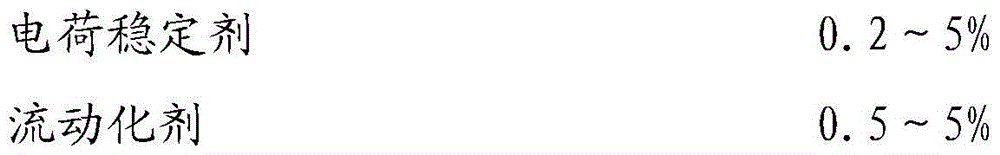

[0032] The preparation method of the above-mentioned fine developer for large-scale development includes the following process: 75-95% by mass of bisphenol A crystalline polyester resin, 2-15% of insulating carbon black, 1-5% of Olefin oligomers, 0.5-5% charge regulator and 0.2-5% charge stabilizer are fully mixed and then added to a twin-screw extruder for high-temperature extrusion and dispersion. Fine developer particles of 6-8 μm are obtained, and then 0.5-5% developer fluidizing agent is mixed and distributed on the surface of the fine developer particles for 3-10 minutes to prepare a fine developer for large-format development.

[0033] The fine developing material particles obtained by the above-mentioned method are regular, fine and uniform up to 6-8 μm, the charged amount is high and stable at 20-30 μc / g, and the fluidity is better than 70%.

Embodiment 1

[0035] Take 9.0kg of bisphenol A crystalline polyester resin (model: TPE-092, produced by Tianjin Institute of Synthetic Materials), 0.15kg of low molecular weight polyethylene (molecular weight 500), 0.7kg of stearic acid surface modified carbon black, 0.1 kg of azo dye charge regulator produced by 1,4-diaminonaphthalene and naphthol AS, and 0.05 kg of calcium stearate charge stabilizer. Put them together into a high-speed mixer and mix for 7.0 minutes at a speed of 1500 rpm. Then carry out high-temperature extrusion dispersion through a twin-screw extruder at a extrusion dispersion temperature of 120° C., and obtain 6.8 μm fine developer particles through crushing and classification. Then take 1.0kg of the above-mentioned 6.8 μm fine developer particles and 5.0g of nano-silica fluidizing agent, 5.0g of nano-sized styrene and methyl acrylate copolymer microparticle fluidizing agent, and mix them at high speed for 5.0 minutes to prepare Large format development of fine develo...

Embodiment 2

[0037] Take 8.8kg of bisphenol A type crystalline polyester resin, 0.18kg of low molecular weight polypropylene (molecular weight 1000), 0.8kg of stearic acid surface modified carbon black, and the couple produced by 1,4-diaminonaphthalene and naphthol AS Nitrogen dye charge regulator 0.16kg, calcium stearate charge stabilizer 0.06kg. Put them together into a high-speed mixer and mix for 7.0 minutes at a speed of 1500 rpm. Then carry out high-temperature extrusion dispersion through a twin-screw extruder at a extrusion dispersion temperature of 130° C., and obtain 7.0 μm fine developer particles through crushing and classification. Then take 1.0kg of the above-mentioned 7.0 μm fine developer particles and 6.0g of nano-silica fluidizing agent, 4.0g of nano-sized styrene and methyl acrylate copolymer microparticle fluidizing agent, and mix them at high speed for 6.0 minutes to prepare Large format development of fine developer materials. The measured performance data are: D50:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com