A micron-scale up-conversion luminescent material and its preparation method

A luminescent material, micron-scale technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of limited luminous intensity, poor dispersion, low yield, etc., and achieve low equipment requirements, regular particle morphology, and high output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

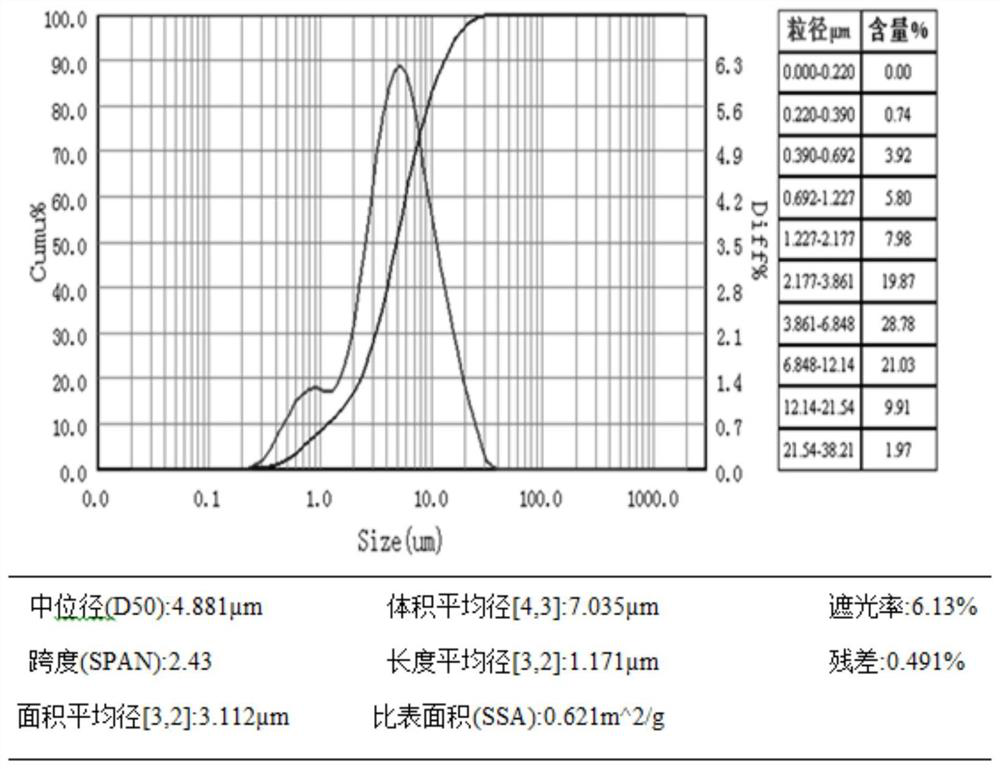

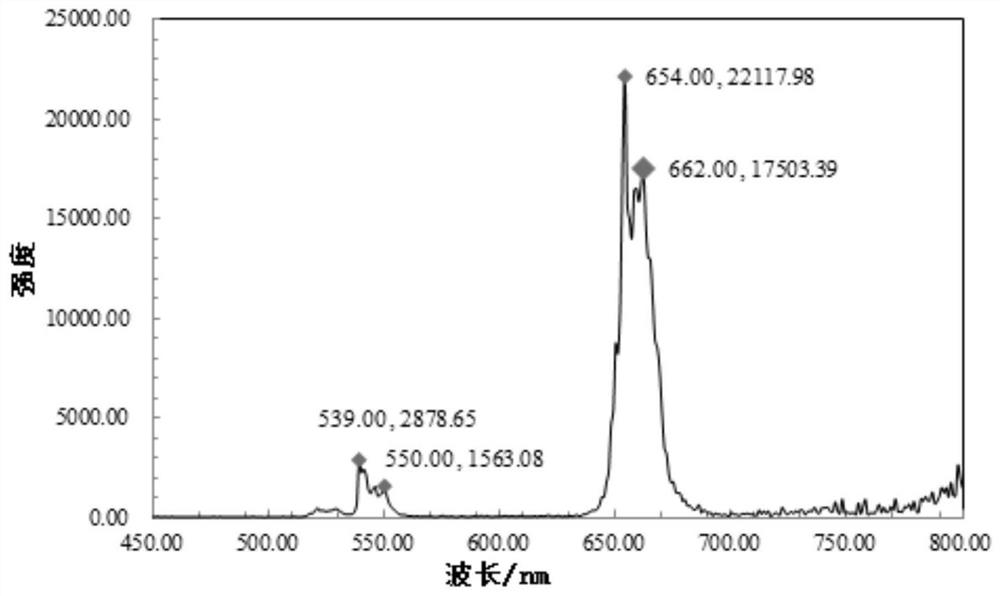

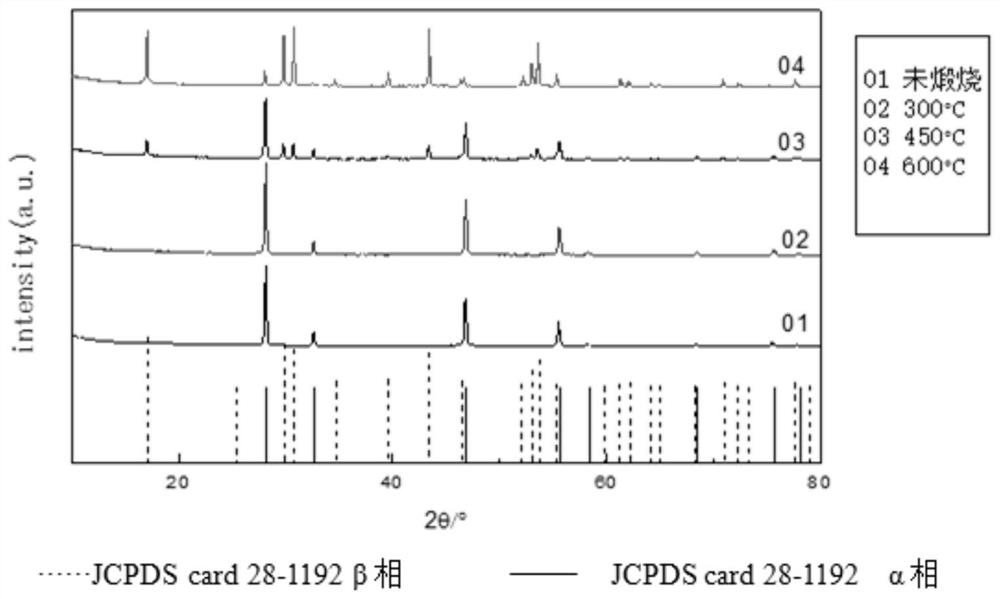

[0049] A micron-scale up-conversion luminescent material (NaYF 4 : Yb, Er), its preparation method comprises the following steps:

[0050] Pour 1L of 1mol / / L NaF solution into the impinging flow reaction, adjust the reactor speed to 800rpm, and the reactor temperature to 50°C; NaF / Er is 12:1, Yb:Y:Er=20:79:1 According to the ratio requirements, prepare the rare earth precursor solution, and then press Er 3+ The molar ratio of / EDTA is 2:1, it is required to quickly mix the prepared rare earth precursor solution and EDTA solution, heat and stir after mixing, the heating temperature is 70°C, and the heating time is 30min, and at the same time, NaOH solution is added dropwise to the mixed solution to reach the pH value 6, then quickly pour the resulting mixture into an impingement flow reactor containing NaF solution, cover the reactor glass cover and react for 1 h, take out the resulting suspension, centrifuge to collect the resulting solid, and wash with deionized water and et...

Embodiment 2

[0056] The preparation method of the micron-scale up-conversion luminescent material described in Example 2 is roughly the same as that in Example 1, except that NaF / Er 3+ is 9:1, Er 3+ / EDTA is 2: 1, the reaction time is 2h, and the reaction temperature is 70°C.

[0057] The particle size and monodispersity analysis result of the product obtained in this embodiment are as follows: Figure 8 As shown, the results show that the particle size of the obtained product is mainly in the range of 0.726-1.325µm, accounting for 16.90% of the total number of particles, the average particle size of the particles is 1.009µm, and has good monodispersity. The yield of the product obtained in this embodiment is 14.56g, and the productive rate is 94.63%.

Embodiment 3

[0059] The preparation method of the micron-scale up-conversion luminescent material described in Example 3 is roughly the same as that in Example 1, except that NaF / Er 3+ is 6:1, Er 3+ / EDTA is 2: 1, the reaction time is 3h, and the reaction temperature is 60°C.

[0060] The particle size and monodispersity analysis result of the product obtained in this embodiment are as follows: Figure 9 As shown, the results show that the particle size of the obtained product is mainly in the range of 0.622-1.163 μm, accounting for 18.76% of the total number of particles, the average particle size of the particles is 0.9650 μm, and has good monodispersity. The yield of the product obtained in this example is 20.46g, and the yield is 99.70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com