Double-rotor pipeline type emulsifying machine

A pipeline type, double rotor technology, applied in the field of emulsifier, can solve the problems of high production cost and lack of promotion, and achieve the effect of good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment describe in detail:

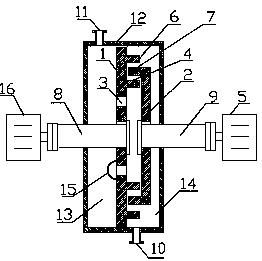

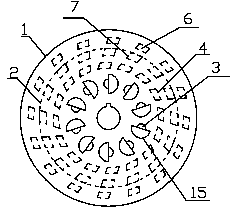

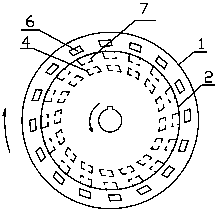

[0032] Such as Figure 1 to Figure 14As shown, the double-rotor pipeline type emulsifier of the present invention includes a housing 12, and the housing 12 is provided with an inner chamber, and the inner chamber of the housing 12 is provided with a left rotor and a right rotor, and the left rotor includes a left disk surface 1, a left rotor The right side of the disk surface 1 is provided with a first helical tooth 6 and a third helical tooth 4 in the circumferential direction, that is, the first helical tooth 6 and the third helical tooth 4 are respectively located on two concentric circles of the left disk surface 1, and the first helical tooth 6 is located on the On the radially outer side of the third helical tooth 4, the center of the left disc surface 1 is provided with a left shaft hole 17, the left shaft hole 17 is provided with a keyway, the left shaft 8 passes through the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com