Halogen-free flame-retardant reinforced type ABS (acrylonitrile-butadiene-styrene) composite material and preparation method thereof

An enhanced and main flame-retardant technology, applied in the field of plastics, can solve the problems of incompatibility between flame-retardant properties and mechanical properties, and achieve the effects of orderly arrangement of atoms, improved mechanical properties, and improved cohesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

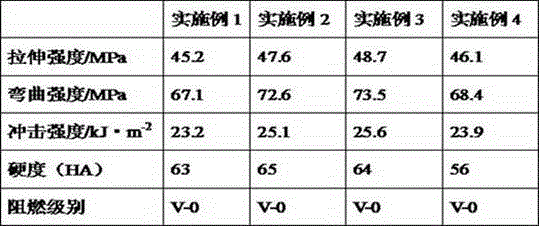

Examples

Embodiment 1

[0032] 55 parts of ABS matrix;

[0033] 18 parts of the main flame retardant matrix;

[0034] 7 parts of synergist matrix;

[0035] 14 parts of reinforcement matrix;

[0036] 2 parts of charring agent;

[0037] 1 part of anti-dripping agent;

[0038] 1 part antioxidant;

[0039] 1 part of paraffin and 1 part of masterbatch.

[0040] in:

[0041] ABS matrix rubber content is 40%;

[0042] The main flame retardant matrix is composed of flame retardant alkyl hypophosphite, aryl diphosphate, resorcinol-bis(dimethylphenyl phosphate) polycondensate and ABS resin, and their weight ratio is 3:2:1.5: 10, wherein the alkyl hypophosphite is dihexyl aluminum hypophosphite, the phosphorus content is 23%-24%, the particle size is 15μm, and the aryl diphosphate is tetrakis-(2,6-di Cresyl) resorcinol diphosphate;

[0043] Synergistic matrix is made up of melamine cyanuric acid, cyanuric acid polyphosphate, microcapsule red phosphorus, carbon black and ABS resin, and their weight ...

Embodiment 2

[0059] 60 parts of ABS matrix;

[0060] 15 parts of the main flame retardant matrix;

[0061] 6 parts of synergist matrix;

[0062] Reinforced matrix 12 parts;

[0063] 3 parts of charcoal agent;

[0064] 1 part of anti-dripping agent;

[0065] 1 part antioxidant;

[0066] 1 part of paraffin and 1 part of masterbatch.

[0067] in:

[0068] ABS matrix rubber content is 40%;

[0069] The main flame retardant matrix is composed of flame retardant alkyl hypophosphite, aryl diphosphate, resorcinol-bis(dimethylphenyl phosphate) polycondensate and ABS resin, and their weight ratio is 3:2:1.5: 10, wherein the alkyl hypophosphite is dihexyl aluminum hypophosphite, the phosphorus content is 23%-24%, the particle size is 15μm, and the aryl diphosphate is tetrakis-(2,6-di Cresyl) resorcinol diphosphate;

[0070] Synergistic matrix is made up of melamine cyanuric acid, cyanuric acid polyphosphate, microcapsule red phosphorus, carbon black and ABS resin, and their weight ratio ...

Embodiment 3

[0086] 65 parts of ABS matrix;

[0087] 12 parts of the main flame retardant matrix;

[0088] 6 parts of synergist matrix;

[0089] 11 parts of reinforcement matrix;

[0090] 2 parts of charring agent;

[0091] 1 part of anti-dripping agent;

[0092] 1 part antioxidant;

[0093] 1 part of paraffin and 1 part of masterbatch.

[0094] in:

[0095] ABS matrix rubber content is 40%;

[0096] The main flame retardant matrix is composed of flame retardant alkyl hypophosphite, aryl diphosphate, resorcinol-bis(dimethylphenyl phosphate) polycondensate and ABS resin, and their weight ratio is 3:2:1.5: 10, wherein the alkyl hypophosphite is dihexyl aluminum hypophosphite, the phosphorus content is 23%-24%, the particle size is 15μm, and the aryl diphosphate is tetrakis-(2,6-di Cresyl) resorcinol diphosphate;

[0097] Synergistic matrix is made up of melamine cyanuric acid, cyanuric acid polyphosphate, microcapsule red phosphorus, carbon black and ABS resin, and their weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com