High-stability long-service-life metal lithium negative electrode material as well as preparation method and application thereof

A negative electrode material, metal lithium technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of large pollution and complexity, and achieve the effects of good conductivity, accelerated electrochemical kinetics, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of a highly stable and long-life metal lithium negative electrode material comprises the following steps:

[0046] (1) Take the fresh lithium sheet out of the argon inert atmosphere and place it in a dry air atmosphere at room temperature (about 25°C).

[0047] (2) Clean the oil and impurities on the surface of the lithium sheet in step (1) with a dry paper towel.

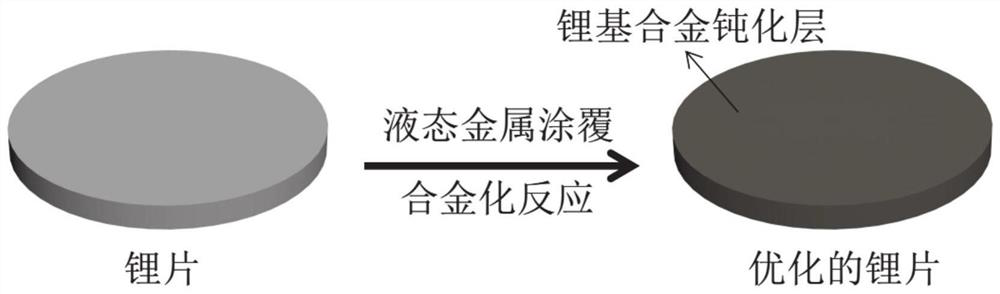

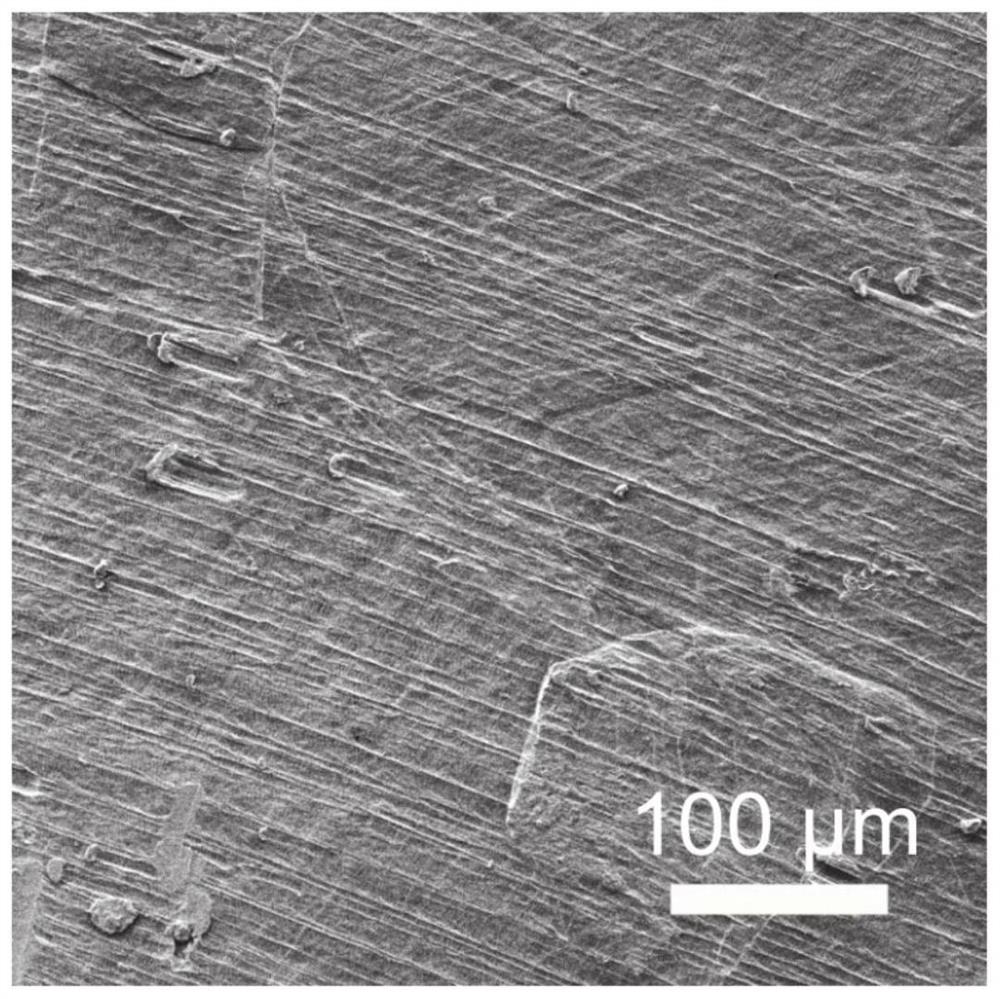

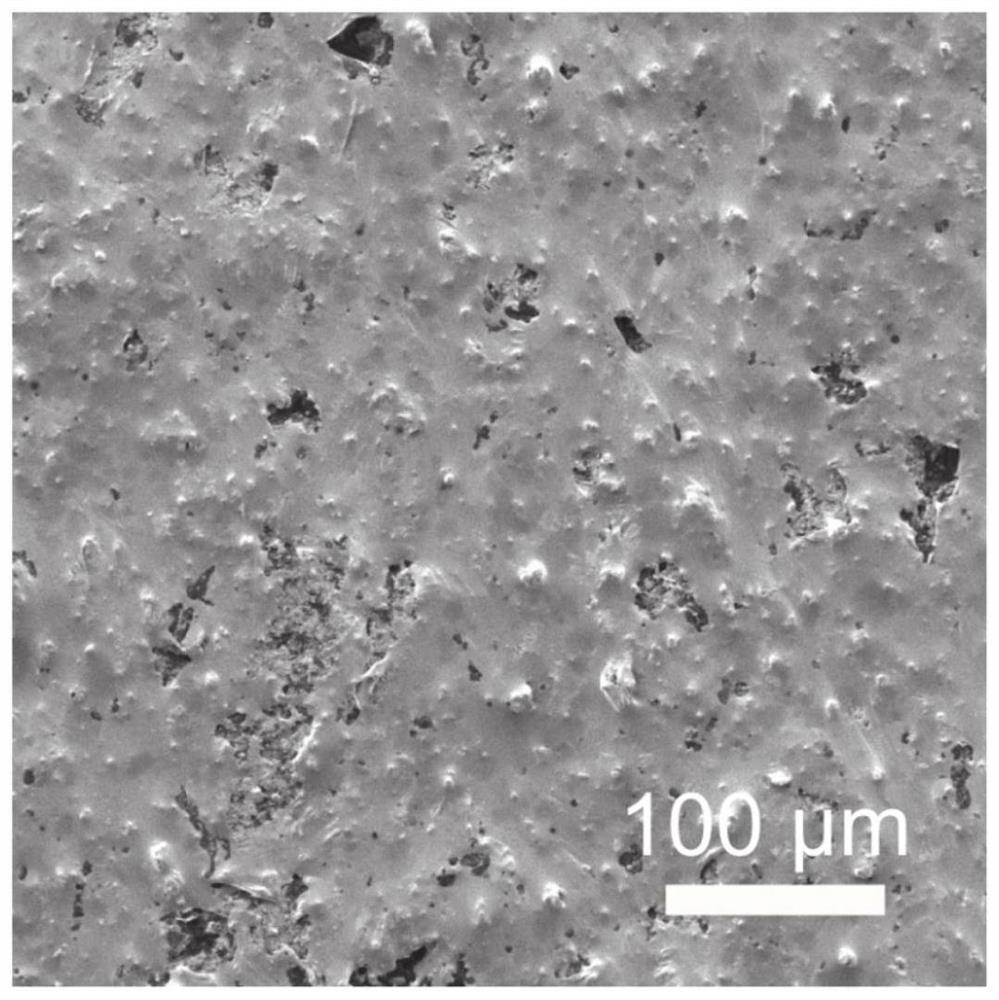

[0048] (3) Quickly and evenly coat a layer of gallium indium tin zinc liquid metal (melting point 3 ℃) on the upper and lower surfaces of the cleaned lithium sheet with a clean small brush, and the loading capacity is 1 mg / cm 2 ,Such as Figure 1-3 shown.

[0049](4) Put the liquid metal-coated lithium sheet in step (3) into an argon inert atmosphere quickly, carry out an alloying reaction at a reaction temperature of 25° C., and the reaction time is 24 hours to obtain the highly stable and long-lived lithium metal anode materials such as Figure 4 and 5 shown.

[0050] (5) Use CR2032 b...

Embodiment 2

[0052] The preparation of a highly stable and long-life metal lithium negative electrode material comprises the following steps:

[0053] (1) Take the fresh lithium sheet out of the argon inert atmosphere and place it in a dry air atmosphere at room temperature (about 25°C).

[0054] (2) Clean the oil and impurities on the surface of the lithium sheet in step (1) with a dry paper towel.

[0055] (3) Quickly and evenly coat a layer of gallium indium tin liquid metal (melting point 5°C) on the upper and lower surfaces of the cleaned lithium sheet with a clean small brush, and the loading capacity is 1 mg / cm 2 .

[0056] (4) Put the liquid metal-coated lithium sheet in step (3) into an argon inert atmosphere quickly, carry out an alloying reaction at a reaction temperature of 25° C., and the reaction time is 24 hours to obtain the highly stable and long-lived lithium metal Negative material.

[0057] (5) Use CR2032 button battery in 1M LiPF 6 -EC / EMC (volume ratio 1:1) liquid...

Embodiment 3

[0059] The preparation of a highly stable and long-life metal lithium negative electrode material comprises the following steps:

[0060] (1) Take the fresh lithium sheet out of the argon inert atmosphere and place it in a dry air atmosphere at room temperature (about 25°C).

[0061] (2) Clean the oil and impurities on the surface of the lithium sheet in step (1) with a dry paper towel.

[0062] (3) Use a clean small brush to quickly and evenly coat a layer of gallium-zinc liquid metal (melting point 25°C) on the upper and lower surfaces of the cleaned lithium sheet, with a loading capacity of 1 mg / cm 2 .

[0063] (4) Put the liquid metal-coated lithium sheet in step (3) into an argon inert atmosphere quickly, carry out an alloying reaction at a reaction temperature of 25° C., and the reaction time is 24 hours to obtain the highly stable and long-lived lithium metal Negative material.

[0064] (5) Use CR2032 button battery in 1M LiPF 6 -EC / EMC (volume ratio 1:1) liquid ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com