Porous polyimide nanometer composite film and preparation method thereof

A polyimide and nanocomposite technology, applied in the field of porous polyimide nanocomposite film and its preparation, can solve the problems of increasing equipment cost and environmental problems, and achieve the effect of avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

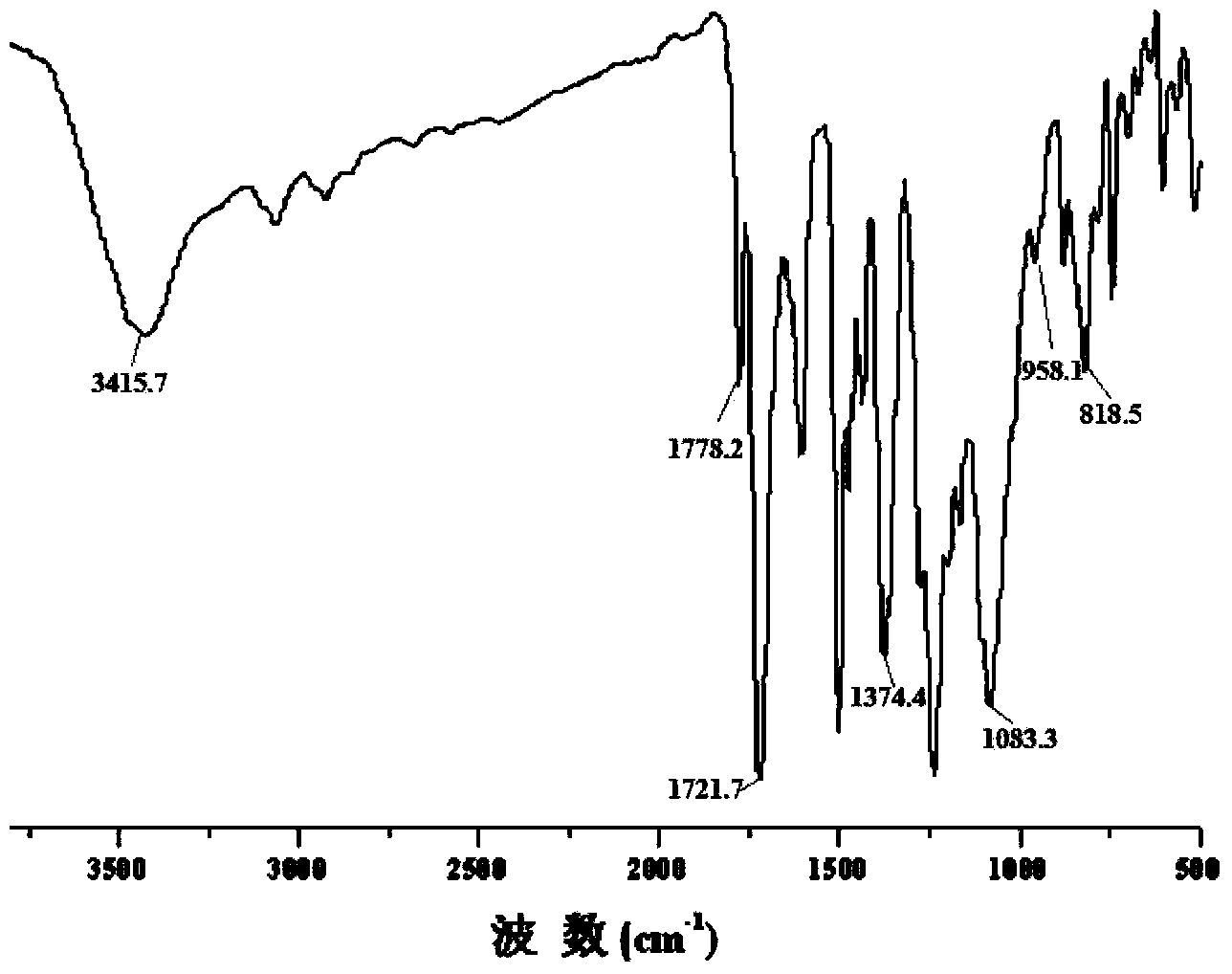

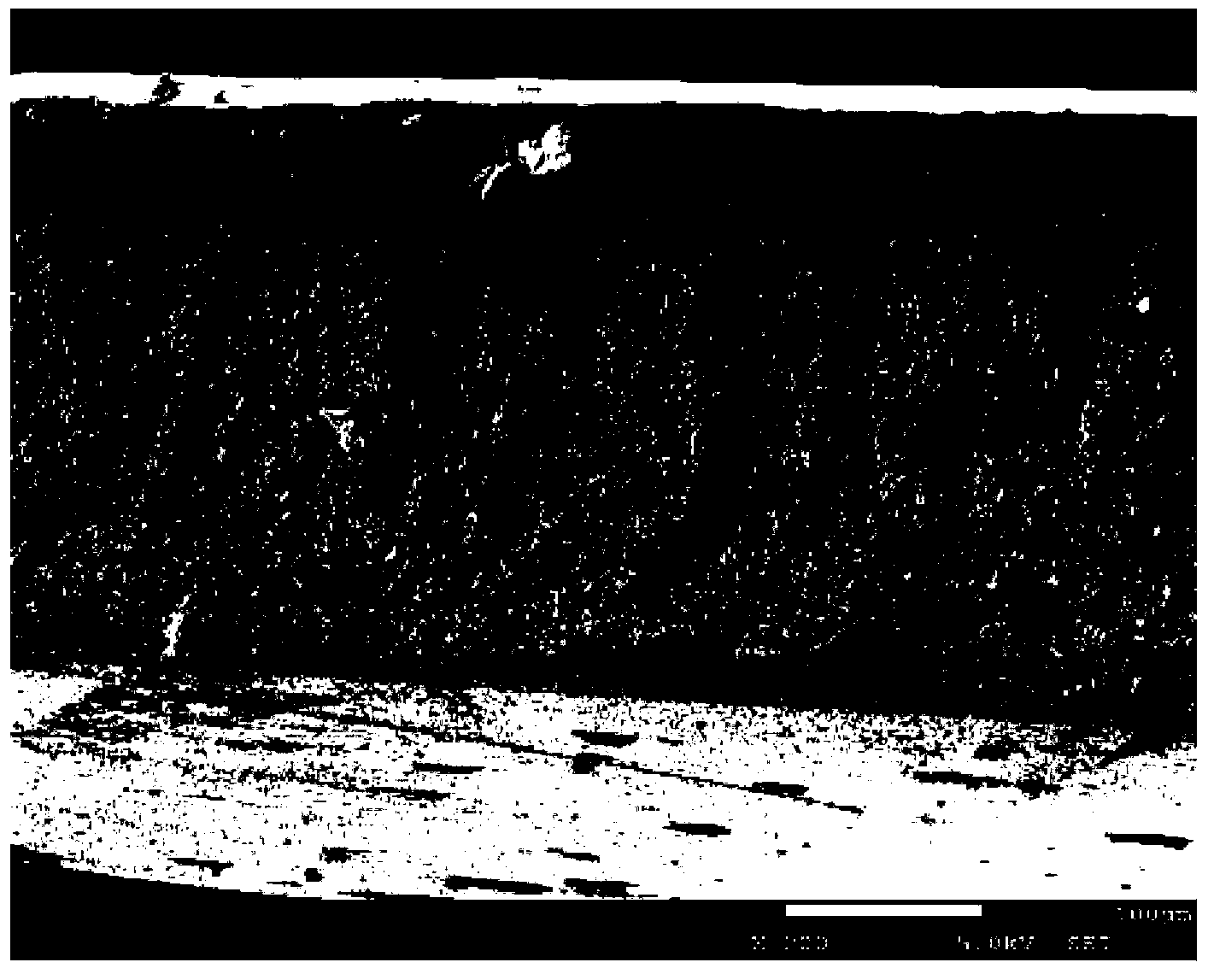

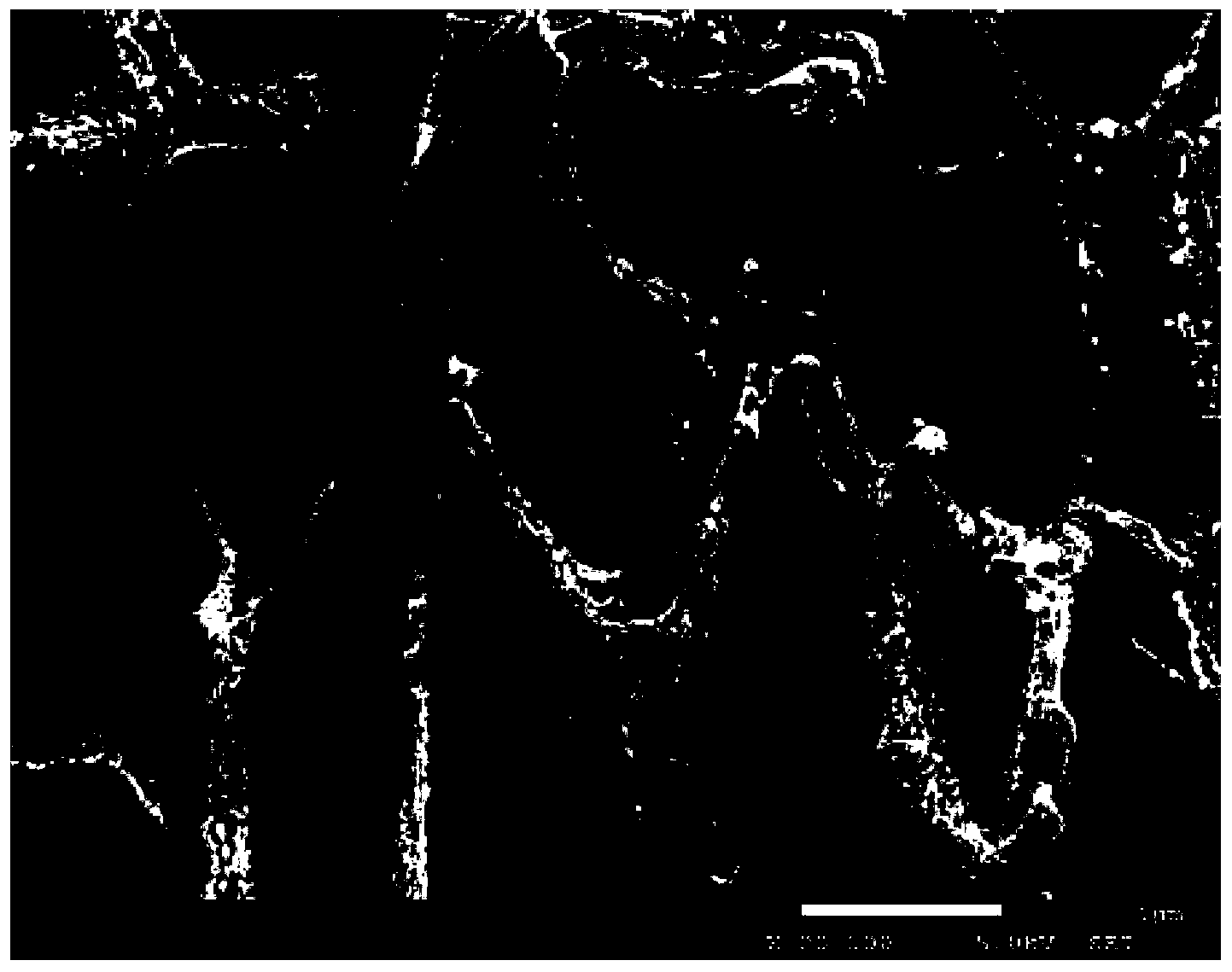

Embodiment 1

[0062] Put 100 grams of N,N-dimethylacetamide solution of polyamic acid with a mass percentage concentration of 20% into a three-necked bottle, then add 20 grams of tetraethyl orthosilicate (TEOS), and then add 3 grams of γ-ammonia Propyltriethoxysilane coupling agent, fully stirred and mixed to form a film. Vacuum the film in a vacuum oven at 80°C for 4 hours to remove the organic solvent, then adopt gradient heating method, keep it at 100°C for half an hour, at 140°C for half an hour, at 160°C for half an hour, at 200°C for 1 hour, and at 240°C Half an hour, heat preservation at 280°C for half an hour, heat preservation at 300°C for 2 hours, imidize the film to prepare a polyimide / nano-silicon dioxide composite film. Put the polyimide / nano-silica composite film into the autoclave, inject carbon dioxide gas into the autoclave, set the temperature in the autoclave to 60°C, and the pressure to 20MPa. Quickly release the pressure to normal pressure, then put it into an oil bath...

Embodiment 2

[0065] Put 100 grams of N,N-dimethylacetamide solution of polyamic acid with a concentration of 20% by mass into a three-necked bottle, then add 16 grams of tetraethyl orthosilicate (TEOS), stir well and mix well to form a film . Vacuum the film in a vacuum oven at 80°C for 4 hours to remove the organic solvent, then adopt gradient heating method, keep it at 100°C for half an hour, at 140°C for half an hour, at 160°C for half an hour, at 200°C for 1 hour, and at 240°C Half an hour, heat preservation at 280°C for half an hour, heat preservation at 300°C for 2 hours, imidize the film to prepare a polyimide / nano-silicon dioxide composite film. Put the polyimide / nano-silica composite film into the autoclave, inject carbon dioxide gas into the autoclave, set the temperature in the autoclave to 30°C, and the pressure to 20MPa. Quickly release the pressure to normal pressure, then put it into an oil bath at 170°C, take it out after 20 seconds of foaming, cool and shape to obtain a p...

Embodiment 3

[0068] First prepare silica sol, add 3.5 grams of tetraethyl orthosilicate (TEOS) to 100 mL of N,N-dimethylacetamide solution and stir for 30 minutes to mix well, then add 0.5 grams of deionized water, and then add hydrochloric acid Adjust the pH value of the mixed solution to 2-3, and reflux the above mixed solution at 80° C. for 2 hours to obtain a uniform and transparent silica sol.

[0069] Put 100 grams of N,N-dimethylacetamide solution of polyamic acid with a concentration of 10% by mass into a three-necked bottle, then add the above-mentioned silica sol into the polyamic acid solution, stir and mix well film forming. Vacuum the film in a vacuum oven at 80°C for 4 hours to remove the organic solvent, then adopt gradient heating method, keep it at 100°C for half an hour, at 140°C for half an hour, at 160°C for half an hour, at 200°C for 1 hour, and at 240°C Half an hour, heat preservation at 280°C for half an hour, heat preservation at 300°C for 2 hours, imidize the film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com