Titanium alloy strong toughening treatment method based on pulse current

A technology of pulse current and processing method, which is applied in the field of material processing and preparation, can solve the problems of high deformation resistance of titanium alloy, narrow processing temperature range, and low utilization rate of deformation heat treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The rolled annealed (thickness is 2.3-2.6mm) Ti-6Al-4V alloy used in the patent of the present invention contains: Al: 6.82%, V: 4.02%, Fe: 0.15% according to the weight percentage , O: 0.12%, C: 0.02%, N: 0.02%, H: 0.006%, the balance of Ti. The titanium alloy was cut into 45mm×10mm×5mm sheet samples with a wire electric discharge machine.

[0025] (2) First polish the surface of the sheet sample with 60#, 400#, 800# sandpaper in order to remove surface oxides or foreign matter. Then put the flake sample into a tube furnace filled with argon gas for 900°C, solution treatment for 1h, and then water-cooled to room temperature.

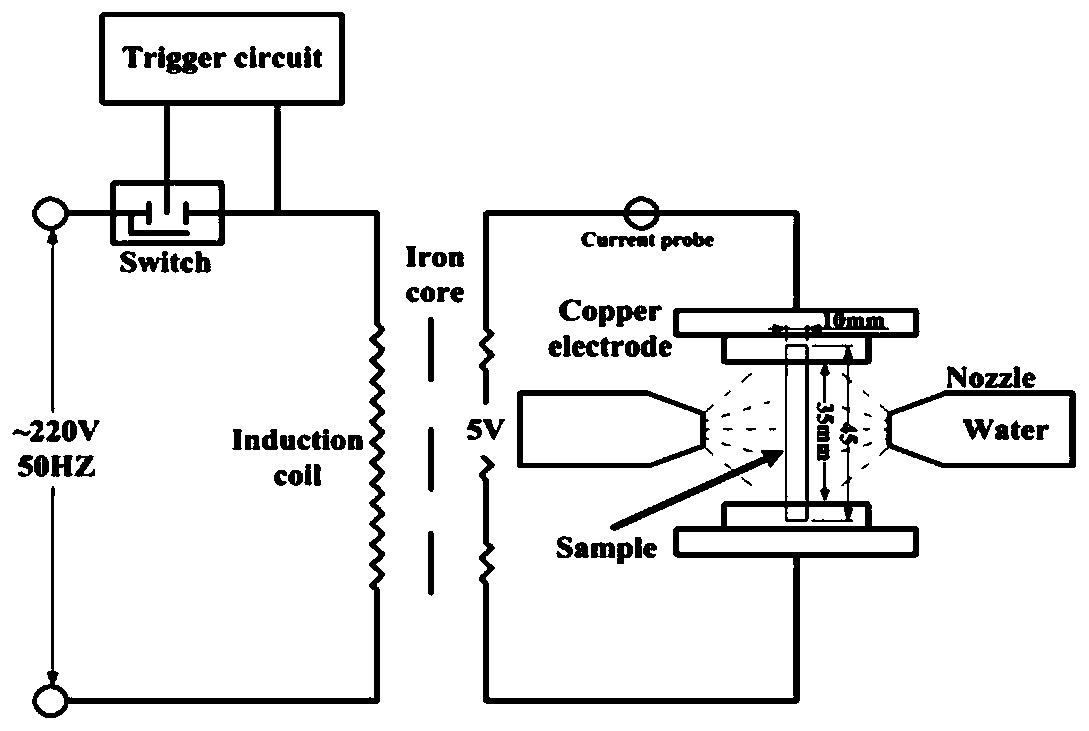

[0026] (3) The sheet-shaped titanium alloy in (2) is treated with pulse current by using the electric pulse device of the self-made thyristor current amplifier circuit, the frequency is 50HZ, the voltage is 5V, and the current density is 5.6×10 7 A / m 2 , The processing time is 460ms, the effective processing length of the sample (that is, ...

Embodiment 2

[0030] (1) The rolled annealed (thickness is 2.3-2.6mm) Ti-6Al-4V alloy used in the patent of the present invention contains: Al: 6.82%, V: 4.02%, Fe: 0.15% according to the weight percentage , O: 0.12%, C: 0.02%, N: 0.02%, H: 0.006%, the balance of Ti. The titanium alloy was cut into 45mm×10mm×5mm sheet samples with a wire electric discharge machine.

[0031] (2) First polish the surface of the sheet sample with 60#, 400#, 800# sandpaper in order to remove surface oxides or foreign matter. Then put the flake sample into a tube furnace filled with argon gas to protect it at 950°C, solution treatment for 1h, and then water-cooled to room temperature.

[0032] (3) The sheet-like titanium alloy in (2) is subjected to pulse current treatment with the electric pulse device of the thyristor current amplifying circuit, the frequency is 50HZ, the voltage is 5V, and the current density is 5.6×10 7 A / m 2 , The processing time was 320ms, the effective processing length of the sample (...

Embodiment 3

[0036] (1) What used in the present embodiment 2 is rolling annealed state (thickness is 2.3~2.6mm) Ti-6Al-4V alloy, and it contains according to weight percentage content: Al: 6.82%, V: 4.02%, Fe: 0.15 %, O: 0.12%, C: 0.02%, N: 0.02%, H: 0.006%, the balance of Ti. The titanium alloy was cut into 45mm×10mm×5mm sheet samples with a wire electric discharge machine.

[0037] (2) First polish the surface of the sheet sample with 60#, 400#, 800# sandpaper in order to remove surface oxides or foreign matter. Then put the flake sample into a tube furnace filled with argon gas for 900°C, solution treatment for 1h, and then water-cooled to room temperature.

[0038] (3) The sheet-like titanium alloy in (2) is subjected to pulse current treatment with the electric pulse device of the thyristor current amplifying circuit, the frequency is 50HZ, the voltage is 5V, and the current density is 5.6×10 7 A / m 2 , The processing time is 280ms, the effective processing length of the sample (that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com