Water-based rechargeable zinc ion battery alloy type negative electrode material and preparation method and application thereof

A zinc-ion battery and anode material technology, applied in battery electrodes, secondary batteries, sustainable manufacturing/processing, etc., can solve the problems of little research, reduced working life, and easy formation of dendrites, etc., to reduce production Cost, increase binding force, effect of increasing binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0045] The third embodiment of the present invention provides an aqueous zinc-ion battery, the negative pole is the alloy-type negative electrode material of the above-mentioned water-system rechargeable zinc-ion battery, and the electrolyte is a zinc-salt system solution, an organic solution containing zinc salt, or a zinc-containing salt standard. solid electrolyte.

[0046] The fourth embodiment of the present invention provides an application of the above-mentioned alloy-type negative electrode material for a water-based zinc ion battery as a current collector for a zinc metal negative electrode of a water-based zinc metal battery.

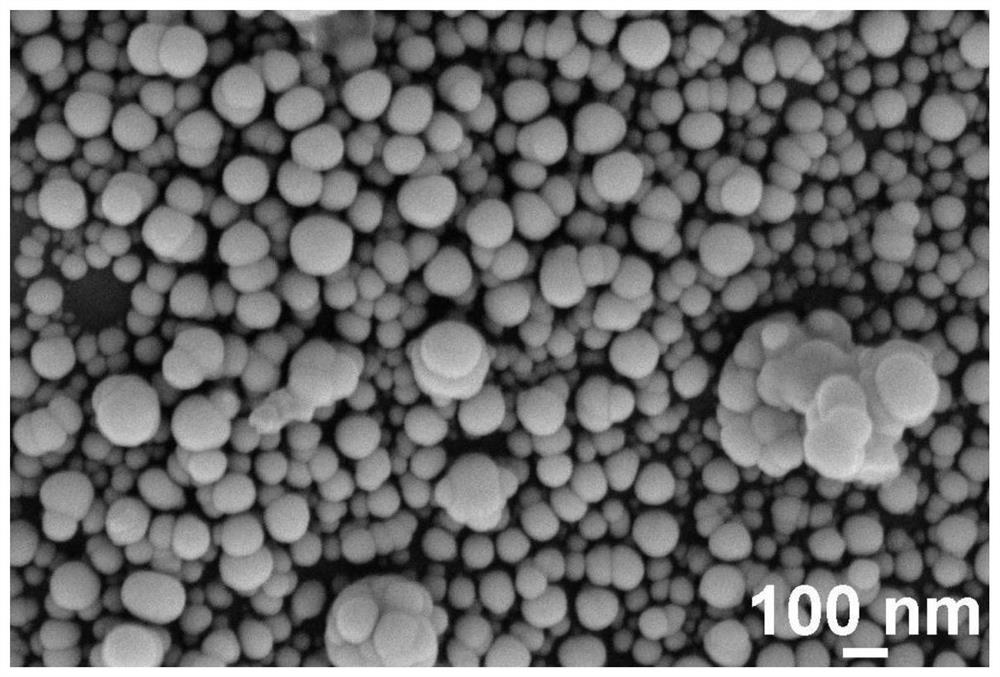

[0047] In the present invention, the inert metal element can be alloyed with Zn or has better solubility at low temperature. When depositing an appropriate amount of inert metal element, it can be used as a nucleation site to reduce the nucleation barrier and reduce nucleation. The overpotential can effectively inhibit the growth of zinc dendr...

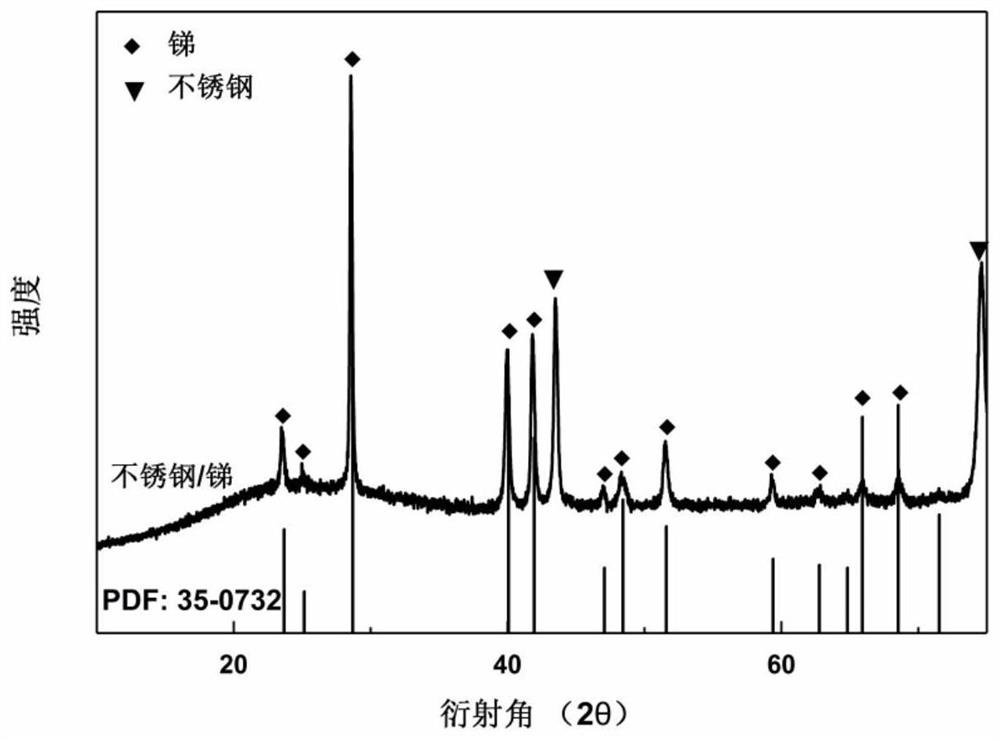

Embodiment 1

[0050] On carbon cloth current collector at 1mAcm -2 In the electroplating solution with an antimony ion concentration of 0.006 moles per liter, constant current electrodeposition, deposition at room temperature without stirring for 15 minutes, then washing with ethanol and deionized water, drying in a vacuum oven at 60 degrees Celsius, and finally After heating at 220° C. for 2 hours under the condition of vacuum degree of 10 Pa, and cooling down to room temperature, an alloy-type negative electrode material carbon cloth / antimony for aqueous zinc-ion batteries can be obtained.

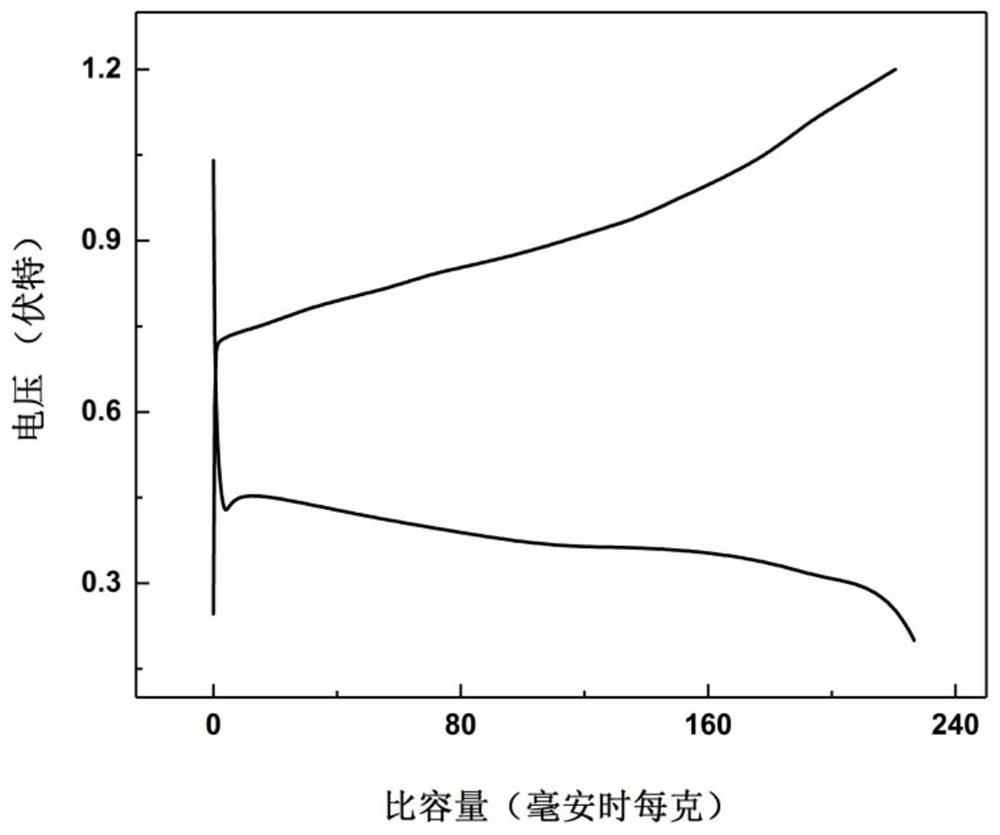

[0051] Main application: used as alloy negative electrode material for aqueous zinc battery, assembled aqueous zinc ion half battery, the prepared carbon cloth / antimony is used as negative electrode material for aqueous zinc ion battery, zinc foil is used for counter electrode and reference electrode, and 2M zinc trifluoromethanesulfonate or zinc sulfate is used as the electrolyte, assembled and elect...

Embodiment 2

[0054] At 1mA cm on a titanium foil (Ti) current collector -2 In the electroplating solution with an antimony ion concentration of 0.006 moles per liter, constant current electrodeposition, deposition at room temperature without stirring for 10 minutes, then washing with ethanol and deionized water, drying in a vacuum oven at 60 degrees Celsius, and finally After heating at 340° C. for 0.5 h under a vacuum of 10 Pa and cooling down to room temperature, Ti / Sb, an alloy-type negative electrode material for aqueous zinc-ion batteries, can be obtained.

[0055] Used as an alloy-type negative electrode material for water-based zinc batteries, assembled with water-based zinc-ion half-cells, the prepared Ti / Sb is used as negative electrode materials for water-based zinc-ion batteries, and zinc foil is used for counter electrodes and reference electrodes, at 2 moles per liter Zinc trifluoromethanesulfonate or zinc sulfate is used as the electrolyte, assembled and electrochemically tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com