Preparation and application of modified ultrathin cellulose diaphragm

A cellulose diaphragm and cellulose technology, applied in the field of electrochemical energy storage, can solve the problems of reducing the specific energy of the aqueous zinc-based energy storage system, the inability of the cellulose diaphragm to be ultra-thin, and the extension of the electrolyte ion transmission distance, etc., to achieve The effect of high stability, low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of Ultrathin Cellulose Separator

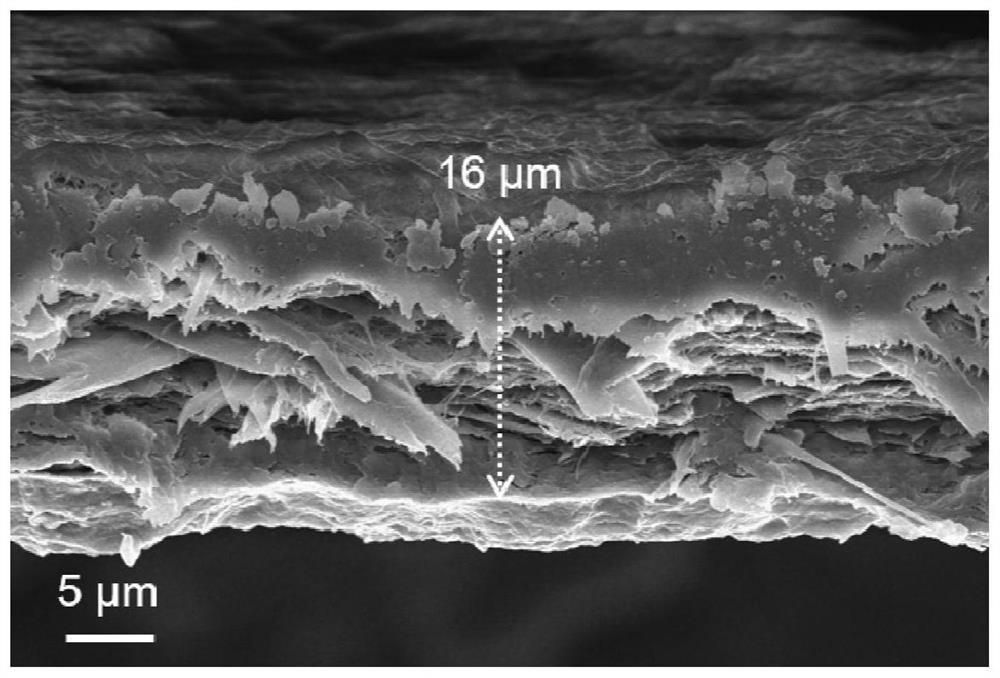

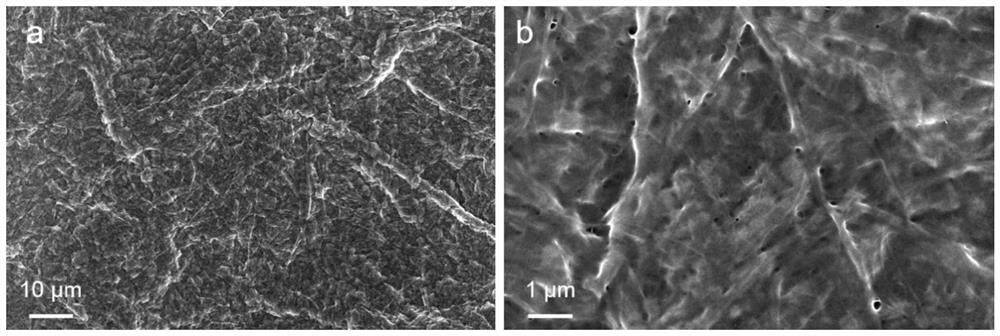

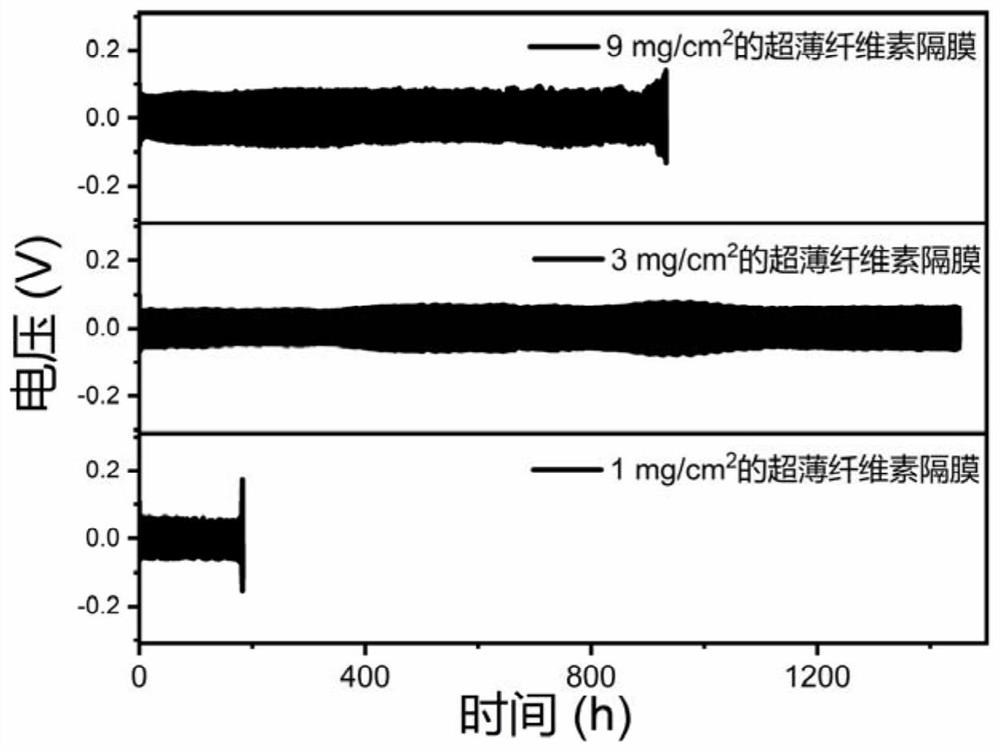

[0046] (1) Disperse commercial hydroxycellulose nanofibers (purchased from Zhejiang Jinjiahao Green Nanomaterials Co., Ltd., model CNF-H1) weighing 12.6, 37.7, and 113.1 mg in deionized water to prepare hydroxycellulose nanofibers. A dispersion liquid with a fiber concentration of 0.5 mg / mL was uniformly dispersed by ultrasound. By the method of vacuum filtration, the above dispersion liquid was suction-filtered onto a mixed cellulose water-based filter membrane (model: Tianjin Jinteng microporous water-based filter membrane, pore size 0.8 μm) substrate. After drying at room temperature for 8 hours, the filter membrane substrate was peeled off to obtain hydroxycellulose nanofibers with loadings of 1, 3, and 9 mg / cm, respectively. 2 of ultra-thin cellulose separators with a loading of 3 mg / cm 2 The thickness of the ultra-thin cellulose separator is about 16 μm, and the thickness cross-sectional diagram is as follows figur...

Embodiment 2

[0051] Preparation of Nanometer Zinc Oxide Modified Ultrathin Cellulose Separator

[0052] (1) Disperse 18.9 mg of hydroxycellulose nanofibers (purchased from Zhejiang Jinjiahao Green Nanomaterials Co., Ltd., model CNF-H1) and 18.9 mg of nano-zinc oxide in deionized water, and the concentration of hydroxycellulose nanofibers is The dispersion liquid with 0.5 mg / mL and nano-zinc oxide concentration of 0.5 mg / mL was uniformly dispersed by ultrasonic. By vacuum filtration, the above mixed dispersion liquid was suction filtered onto a mixed cellulose water-based filter membrane (model: Tianjin Jinteng microporous water-based filter membrane, pore size 0.8 μm) substrate. After drying at room temperature for 8 hours, the filter membrane substrate was peeled off, and the loading of hydroxycellulose nanofibers was 1.5 mg / cm. 2 , the nano-zinc oxide loading is 1.5mg / cm 2 Nano-zinc oxide modified ultrathin cellulose separator.

[0053] (2) A zinc sheet with a diameter of 10 mm and a ...

Embodiment 3

[0056] Preparation of Halloysite Nanotubes Modified Ultrathin Cellulose Separator

[0057](1) 18.9 mg of hydroxycellulose nanofibers (purchased from Zhejiang Jinjiahao Green Nanomaterials Co., Ltd., model CNF-H1) and 18.9 mg of commercial natural halloysite nanotubes (with an outer diameter of about 50 nm and an inner diameter of 15 -20nm, 100-1500nm in length) dispersed in deionized water to prepare a dispersion liquid with hydroxycellulose nanofiber concentration of 0.5mg / mL and halloysite concentration of 0.5mg / mL, and uniformly dispersed by ultrasonic. By vacuum filtration, the above mixed dispersion liquid was suction filtered onto a mixed cellulose water-based filter membrane (model: Tianjin Jinteng microporous water-based filter membrane, pore size 0.8 μm) substrate. After drying at room temperature for 8 hours, the filter membrane substrate was peeled off, and the loading of hydroxycellulose nanofibers was 1.5 mg / cm. 2 , the loading of halloysite nanotubes is 1.5 mg / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com