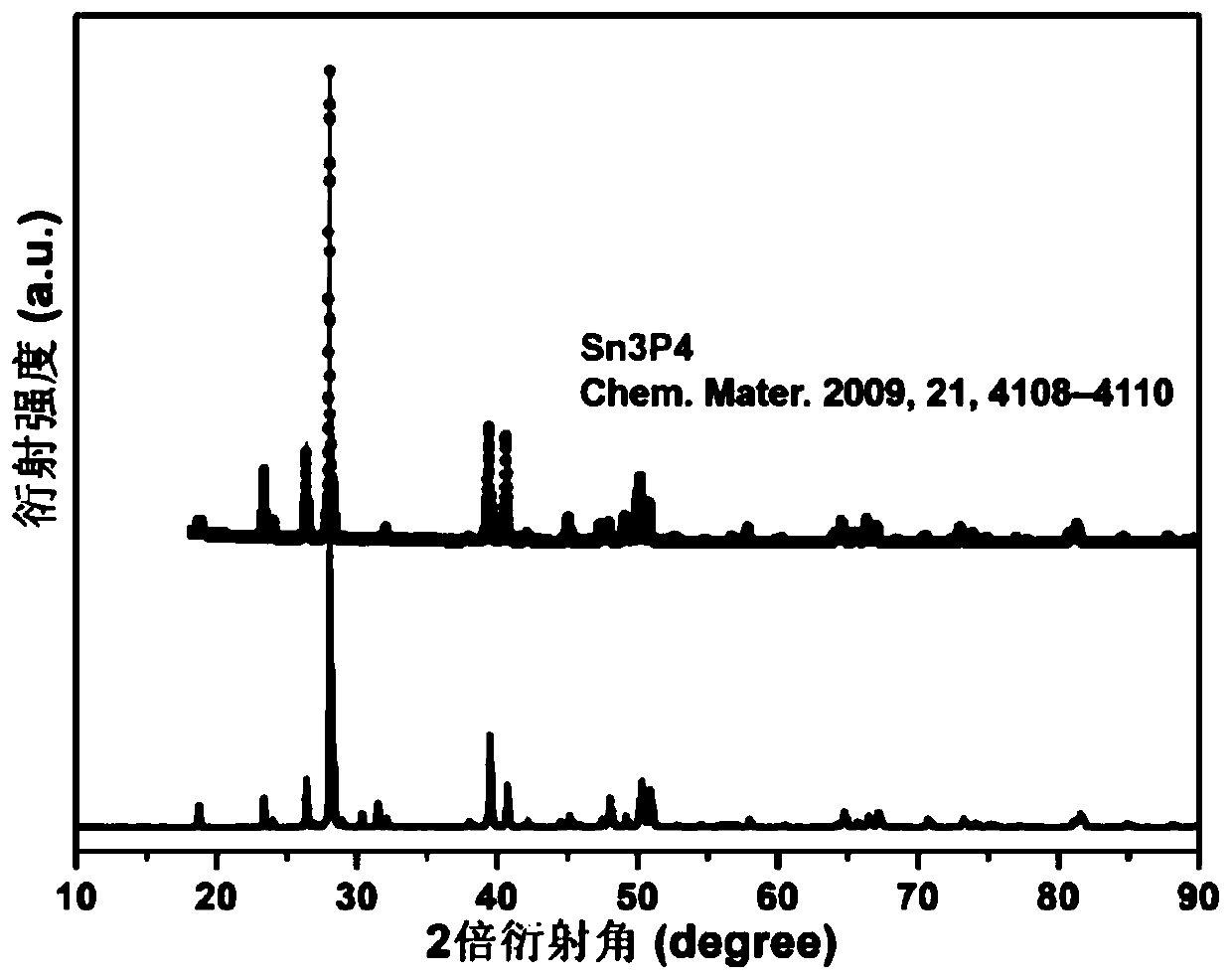

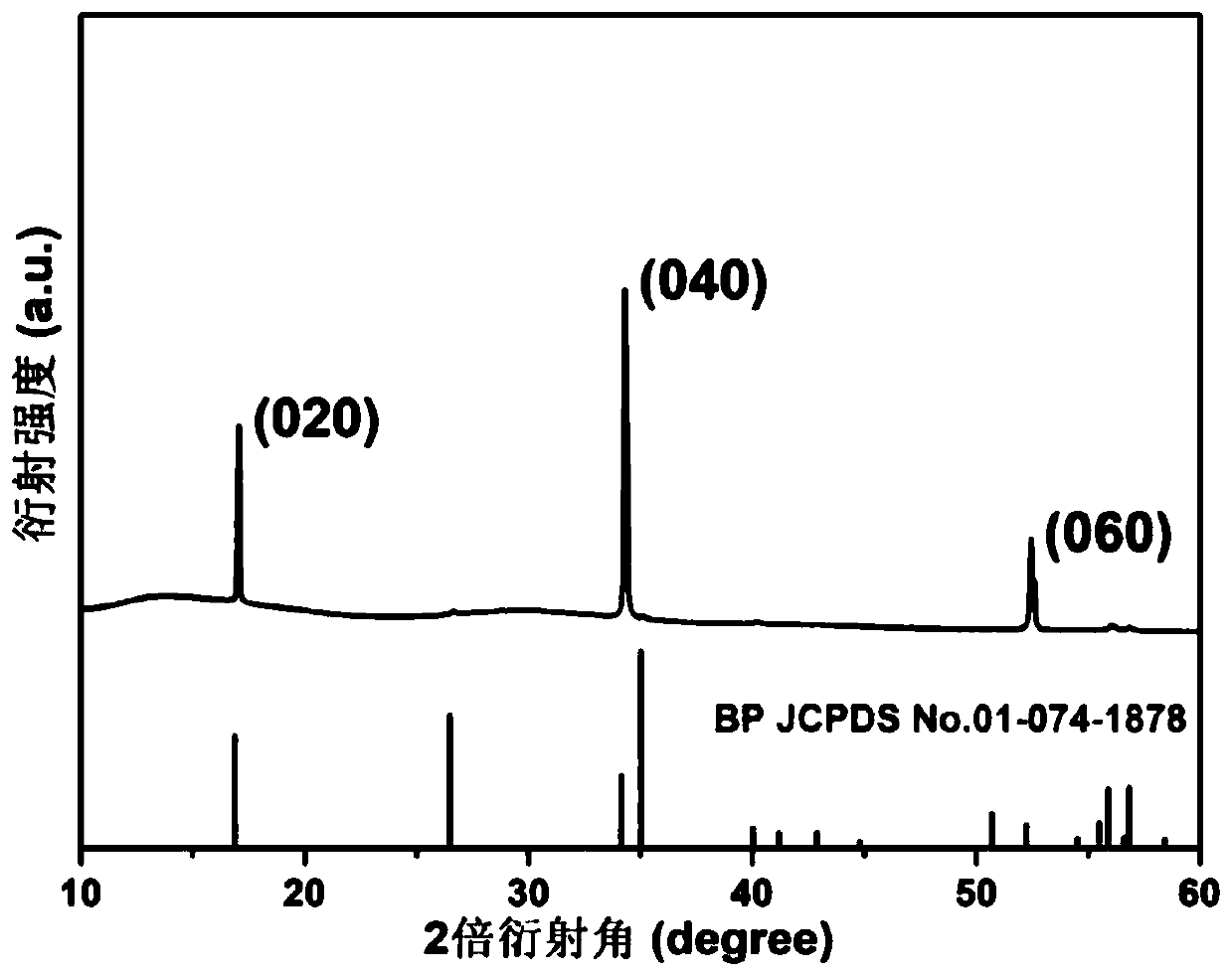

Preparation method of Sn3P4 induced two-dimensional black phosphorus crystals

A technology of black phosphorus and crystals, which is applied in the field of efficient preparation of two-dimensional black phosphorus crystals induced by Sn3P4, can solve the problems of few reports on the growth of catalytic two-dimensional black phosphorus crystals, difficult to guarantee the controllability of the reaction process, difficult operation and high risk factor , to achieve the effect of less impurities, reduce energy consumption, and prevent tube explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of Sn 3 P 4 The method for inducing the efficient preparation of two-dimensional black phosphorus crystals, the specific preparation steps are as follows:

[0048] 1) Under an inert atmosphere (argon), weigh 117.69 mg of red phosphorus raw material and 356.1 mg of tin powder into the bottom of a single-ended sealed quartz tube, and seal the opening with parafilm for later use.

[0049] 2) Remove the sealing film, quickly use the vacuum sealing system to seal the reaction raw materials inside the quartz tube, and the vacuum condition pressure in the quartz tube is below 1 Pa.

[0050] 3) Put the sealed quartz tube in the tube furnace, and set the heating and cooling program to heat the quartz tube. The specific procedure is as follows: at room temperature, the temperature was raised to 450 °C for 1 hour, and then kept for 144 hours; then the temperature was lowered, and the heating process was stopped on the basis of the holding temperature, and the tube furnace...

Embodiment 2

[0057] A kind of Sn 3 P 4 The method for inducing the efficient preparation of two-dimensional black phosphorus crystals, the specific preparation steps are as follows:

[0058] 1) Under an inert atmosphere (argon), weigh 130.07 mg of red phosphorus raw material and 356.1 mg of tin bar at the bottom of a single-ended sealed quartz tube, and seal the opening with parafilm for later use.

[0059] 2) Remove the sealing film, quickly use the vacuum sealing system to seal the reaction raw materials inside the quartz tube, and the vacuum condition pressure in the quartz tube is below 1 Pa.

[0060] 3) Put the sealed quartz tube in the tube furnace, and set the heating and cooling program to heat the quartz tube. The specific procedure is as follows: at room temperature, the temperature was raised to 520 °C for 2 hours, and then kept for 192 hours; then the temperature began to drop, and on the basis of the holding temperature, it was lowered to room temperature for 120 minutes. A...

Embodiment 3

[0067] A kind of Sn 3 P 4 The method for inducing the efficient preparation of two-dimensional black phosphorus crystals, the specific preparation steps are as follows:

[0068] 1) Under an inert atmosphere (argon), weigh 123.88 mg of red phosphorus raw material and 356.1 mg of tin foil to the bottom of a single-head sealed quartz tube, and seal the opening with parafilm for later use.

[0069] 2) Remove the sealing film, quickly use the vacuum sealing system to seal the reaction raw materials inside the quartz tube, and the vacuum condition pressure in the quartz tube is below 1 Pa.

[0070] 3) Put the sealed quartz tube in the tube furnace, and set the heating and cooling program to heat the quartz tube. The specific procedure is as follows: at room temperature, the temperature was raised to 500 °C for 1 hour, and then kept for 168 hours; then the temperature began to drop, and on the basis of the holding temperature, it was lowered to room temperature for 60 minutes. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com