Crystalline nucleus early-strength polycarboxylic acid water reducer and preparation method thereof

An early-strength, polycarboxylic acid technology, applied in the field of crystal nucleus early-strength polycarboxylate water reducing agent and its preparation, can solve the problems of high price and wide use, complex reaction mechanism, expansion and cracking of concrete surface, and achieves the technological progress. The effect of easy parameter control, reduced nucleation barrier and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0024] To prepare crystal nucleus early-strength polycarboxylate superplasticizer, the specific steps are as follows:

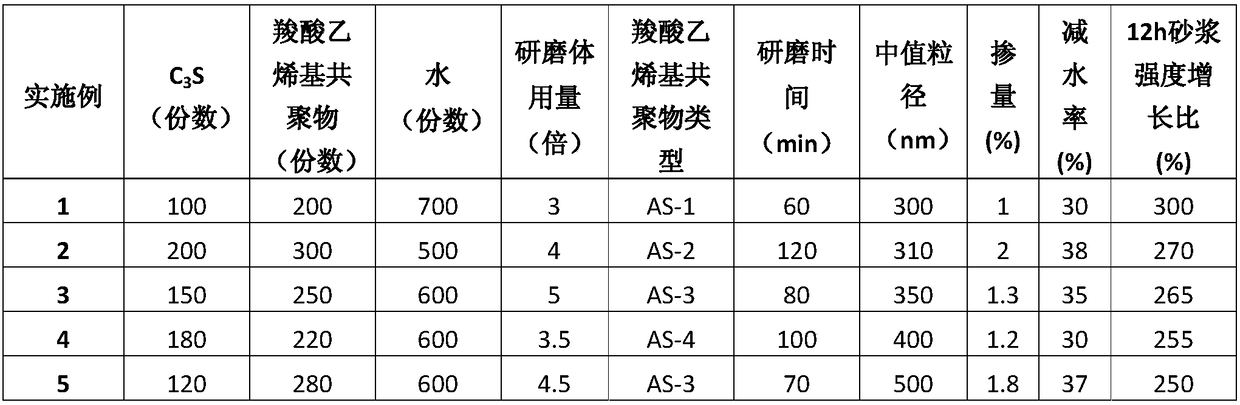

[0025] Tricalcium silicate (C 3 S), Carboxylic acid vinyl copolymer and deionized water are put into the ball mill tank in proportion, and then add zirconia grinding body, the particle size ratio of zirconia grinding body is 5mm: 3mm: 1mm: 0.6mm = 3: 3: 4 : 4. Grind for 60-120min until the crystal nucleus early strength polycarboxylate water reducer with a median particle size of less than 500nm is obtained. The crystal nucleus early-strength polycarboxylate superplasticizer prepared in Example 1-5 was mixed into ordinary Portland cement mortar, and its water reducing rate and 12h mortar strength growth ratio, raw material ratio, process parameters and product were tested. The performance results are shown in Table 2. The particle size is measured by a laser particle size analyzer, and the mortar strength growth ratio refers to the standard GB8076-2008.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com