Graphene-base nanocrystal-nucleus early-strength admixture and preparation method thereof

A graphene-based, nanocrystalline technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of reduced strength and durability of concrete, reduce nucleation barriers, improve early strength, and produce The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

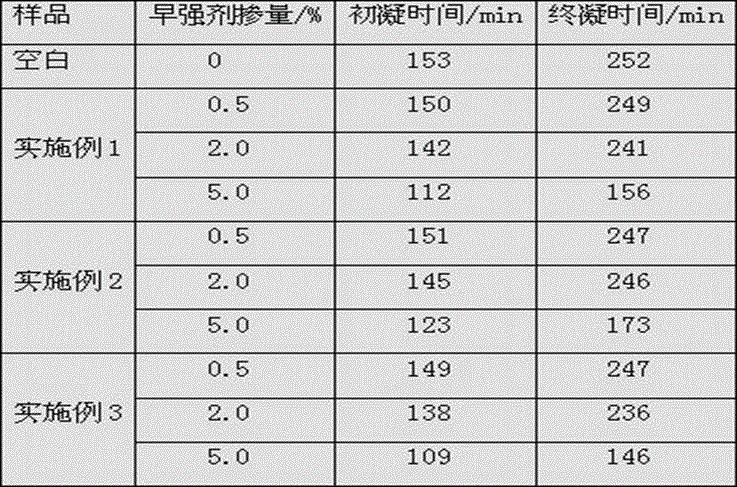

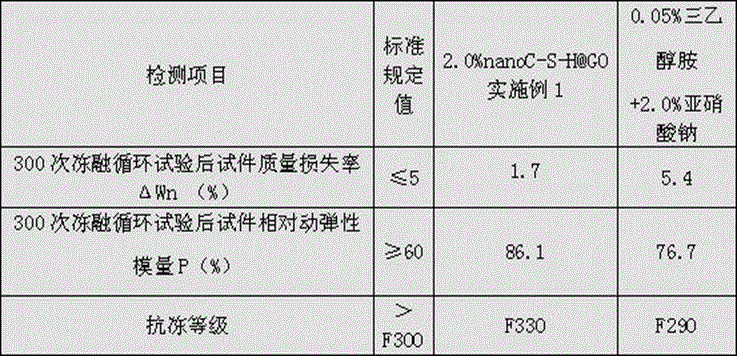

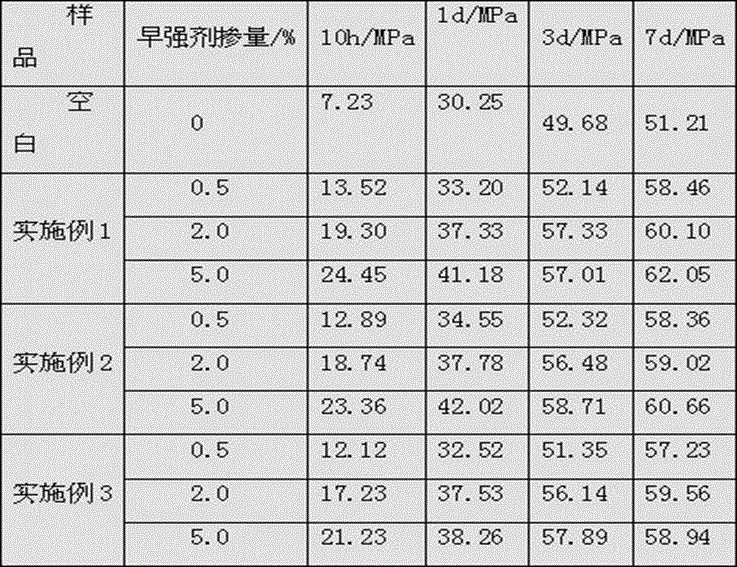

Embodiment 1

[0021]Example 1: A graphene-based nanocrystalline nucleus accelerator, referred to as nanoC-S-H@GO, with calcium nitrate as the Ca source and sodium silicate as the Si source, and the C-S-H nanocrystalline nucleus is formed by in-situ precipitation at room temperature Loaded on graphene oxide, nanoC-S-H@GO was obtained; the molar ratio of Ca to Si was 1:1, and graphene oxide, namely GO, accounted for 0.3% of the total mass of nanoC-S-H@GO. In nanoC-S-H@GO, C-S-H@GO is a composite nanocrystal grain composed of calcium silicate hydrate and graphene oxide, a non-stoichiometric compound with an indeterminate composition, with (CaO) x ·SiO2 2 (H 2 O) y @GO said, x, y are variable.

[0022] Its preparation method comprises the following steps:

[0023] (1) Graphene oxide hydrosol, that is, GO hydrosol, was prepared by the Hummer method, and the specific steps were as follows:

[0024] A. Preparation of pre-oxidized graphite powder: Add 5g graphite powder to 12ml concentrated H ...

Embodiment 2

[0027] Example 2: A graphene-based nanocrystalline nucleus accelerator, referred to as nanoC-S-H@GO, with calcium nitrate as the Ca source and sodium silicate as the Si source, and the C-S-H nanocrystalline nucleus is formed by in-situ precipitation at room temperature Loaded on graphene oxide, nanoC-S-H@GO was obtained; the molar ratio of Ca to Si was 1:1.5, and graphene oxide, namely GO, accounted for 0.5% of the total mass of nanoC-S-H@GO.

[0028] Its preparation method comprises the following steps:

[0029] (1) Graphene oxide hydrosol, GO hydrosol, was prepared by the Hummer method. The specific steps were prepared according to the method described in Example 1, and the concentration of graphene oxide GO hydrosol was 16.4 mg / mL.

[0030] (2) Dissolve 21.3g of sodium silicate nonahydrate in 100 ml of deionized water, weigh 11.8g of calcium nitrate tetrahydrate and 7.8 mL of GO in 100 mL of ionized water to make a uniform brown sol without particles, At a stirring speed o...

Embodiment 3

[0031] Example 3: A graphene-based nanocrystalline nucleus accelerator, referred to as nanoC-S-H@GO, with calcium nitrate as the Ca source and sodium silicate as the Si source, and the C-S-H nanocrystalline nucleus is formed by in-situ precipitation at room temperature Loaded on graphene oxide, nanoC-S-H@GO is obtained; the molar ratio of Ca to Si is 1:3, and graphene oxide, namely GO, accounts for 1% of the total mass of nanoC-S-H@GO.

[0032] Its preparation method comprises the following steps:

[0033] (1) Graphene oxide hydrosol, GO hydrosol, was prepared by the Hummer method. The specific steps were prepared according to the method described in Example 1, and the concentration of graphene oxide GO hydrosol was 16.4 mg / mL.

[0034] (2) Dissolve 42.6 g of sodium silicate nonahydrate in 100 ml of deionized water, weigh 11.8 g of calcium nitrate tetrahydrate and 33.2 mL of GO in 100 mL of ionized water to make a uniform brown sol without particles, and dissolve it at 300 rpm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com