Sulphoaluminate cement and preparation method thereof

A technology of sulfoaluminate cement and calcium sulfosilicate, which is applied in the field of cement preparation, can solve problems such as harmful minerals, achieve high early strength, simple preparation, and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

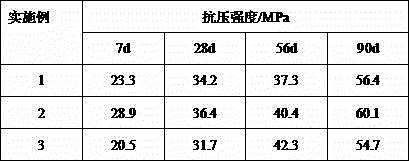

Examples

Embodiment 1

[0033] A method for preparing sulfoaluminate cement containing calcium sulfosilicate minerals, the specific implementation steps are as follows:

[0034] a. Preparation of cement raw meal:

[0035] 56 parts by mass of limestone, 27 parts by mass of bauxite, and 17 parts by mass of phosphogypsum, and then grind each component together to a fineness of 100-200 mesh to obtain raw meal ingredients.

[0036] b. Preparation of cement clinker:

[0037] Put the raw meal prepared in step a into a rotary kiln for the first calcining, control the calcining temperature to 1350°C and calcining time for 30 minutes to obtain cement clinker; then calcinate the clinker again, control the calcining temperature to 1200°C for the holding time 60 minutes; the clinker is cooled by a grate cooler to obtain sulphoaluminate cement clinker containing calcium sulphosilicate minerals.

[0038] c. Preparation of cement:

[0039] Add 5 parts by mass of natural dihydrate gypsum to the cement clinker burn...

Embodiment 2

[0043] A method for preparing sulfoaluminate cement containing calcium sulfosilicate minerals by adopting a secondary calcination process, the specific implementation steps are as follows:

[0044] a. Preparation of cement raw meal:

[0045] 55 parts by mass of limestone, 20 parts by mass of bauxite, 5 parts by mass of sandstone, and 20 parts by mass of phosphogypsum, and then grind and mix each component to a fineness of 100-200 mesh to obtain raw meal ingredients.

[0046] b. Preparation of cement clinker:

[0047] Put the raw meal prepared in step a into a rotary kiln for the first calcining, control the calcining temperature to 1300°C and calcining time for 30 minutes to obtain cement clinker, then calcinate the clinker again and control the calcining temperature to 1150°C to keep it warm After 120 minutes, the clinker was cooled by a grating cooler to obtain sulphoaluminate cement clinker.

[0048] c. Preparation of cement:

[0049] Add 5 parts by mass of natural dihyd...

Embodiment 3

[0052] A method for preparing sulfoaluminate cement containing calcium sulfosilicate minerals by adopting a secondary calcination process, the specific implementation steps are as follows:

[0053] a. Preparation of cement raw meal: 50 parts by mass of limestone, 30 parts by mass of electrolytic manganese slag, 20 parts by mass of bauxite, and then grind each component together to a fineness of 100-200 mesh to obtain raw meal ingredients.

[0054] b. Preparation of cement clinker:

[0055] Put the raw meal prepared in step a into a rotary kiln for the first calcining, control the calcining temperature to 1350°C and calcining time for 30 minutes to obtain cement clinker, then calcinate the clinker again and control the calcining temperature to 1220°C to keep it warm After 120 minutes, the clinker was cooled by a grate cooler to obtain sulphoaluminate cement.

[0056] c. Preparation of cement:

[0057] Add 5 parts by mass of natural dihydrate gypsum to the cement clinker burne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com