Graphene aerogel microspheres and preparation method and application thereof

A graphene airgel and graphene technology, applied in the direction of microsphere preparation, microcapsule preparation, chemical instrument and method, etc., can solve the problem of sol-gelling reagents without graphene hydrogel microspheres, which are not suitable for graphite Solve the problems of preparation and low production efficiency of olefin airgel microspheres, and achieve the effects of easy modification and loading, rich oxygen-containing functional groups, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

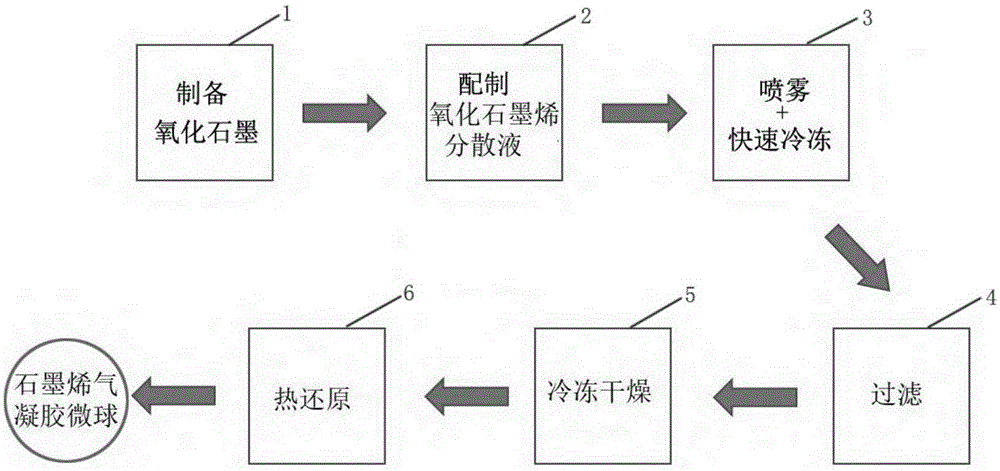

Method used

Image

Examples

Embodiment 1

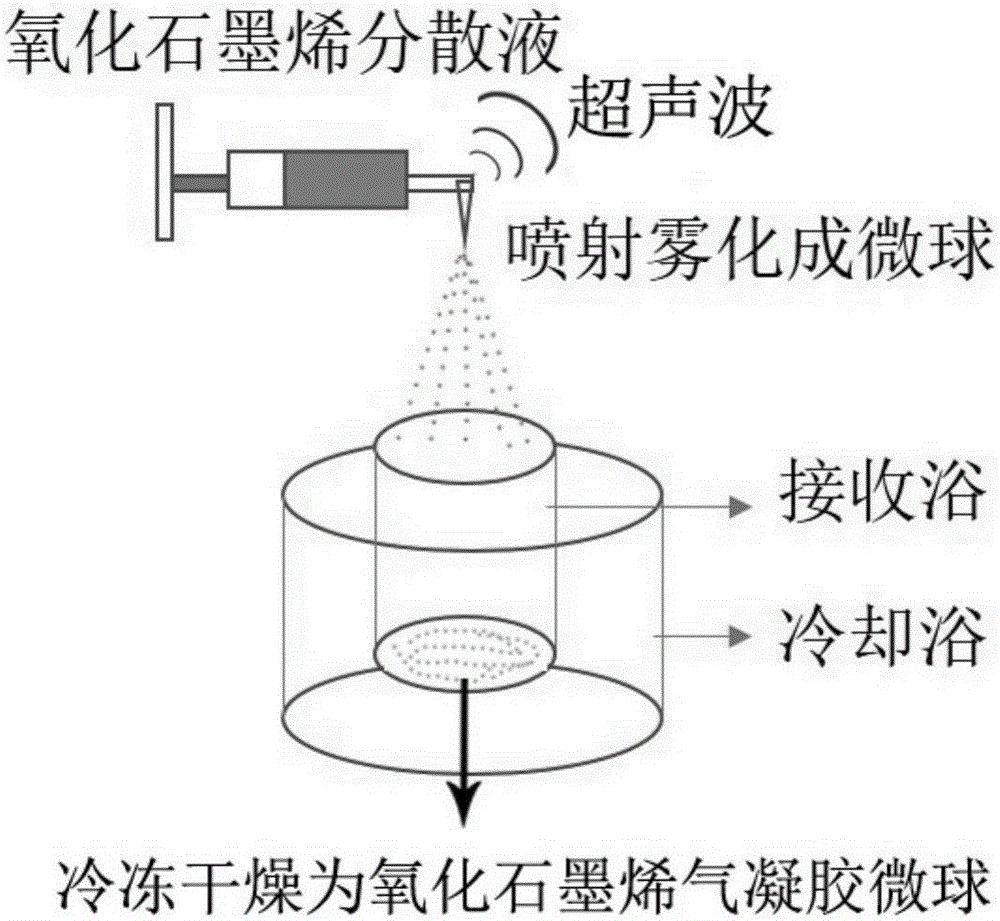

[0041] (1) Preparation of graphite oxide: natural graphite was prepared into graphite oxide by Brodie oxidation method.

[0042] (2) Preparation of graphene oxide water dispersion: at room temperature, mix 0.75g of graphite oxide prepared by Brodie oxidation method with 100ml of deionized water, place in an ultrasonic cleaner, 200W ultrasonic dispersion for 20 minutes and then stir overnight to obtain a uniform dispersion. Dark brown 7.5mg / ml graphene oxide aqueous dispersion.

[0043] (3) Put crushed ice in a well-insulated open-top Dewar flask, add sodium chloride powder, and stir evenly to form a crushed ice / sodium chloride cooling bath. Place the beaker with ethyl acetate in a crushed ice / NaCl cooling bath as receiver. At the same time, put the prepared 7.5mg / ml graphene oxide aqueous dispersion into the syringe on the electrostatic spray device, adjust the height of the nozzle of the syringe so that it is separated from the receiving liquid by a suitable distance, adjust...

Embodiment 2

[0047] (1) Preparation of graphite oxide: natural graphite was prepared as graphite oxide by the improved HUMMER method.

[0048] (2) Preparation of graphene oxide aqueous dispersion: at room temperature, mix 1.5g of graphite oxide prepared by the improved HUMMER method with 100ml of deionized water, place in an ultrasonic cleaner, 400W ultrasonic dispersion for 35min and stir overnight to obtain a uniform dispersion 15 mg / ml graphene oxide aqueous dispersion in dark brown color.

[0049](3) Place ethyl acetate in an open Dewar flask with good heat preservation, and add a large amount of liquid nitrogen while stirring until a slush-like liquid nitrogen / ethyl acetate cooling bath is formed. Put the beaker containing toluene and n-hexane into a liquid nitrogen / ethyl acetate cooling bath to cool as the receiving liquid. At the same time, put the prepared 15mg / ml graphene oxide aqueous dispersion into the syringe on the ultrasonic spray device, adjust the height of the nozzle noz...

Embodiment 3

[0053] (1) Preparation of graphite oxide: natural graphite is prepared as graphite oxide by the HUMMER method.

[0054] (2) Preparation of graphene oxide aqueous dispersion: at room temperature, mix 0.5 mg of graphite oxide prepared by the HUMMER method with 100 ml of deionized water, place in an ultrasonic cleaner, 300 W ultrasonic dispersion for 30 min and then stir overnight to obtain a uniformly dispersed dark brown 5mg / ml graphene oxide aqueous dispersion.

[0055] (3) Put the acetone in a well-insulated open Dewar flask, and add dry ice pieces while stirring until it is almost impossible to stir, that is, a viscous dry ice / acetone cooling bath is formed. Cool the beaker containing ethyl acetate and n-heptane in a dry ice / acetone cooling bath as the receiver solution. At the same time, put the prepared 5mg / ml graphene oxide water dispersion into the pressure chamber on the pressure spray device, adjust the height of the nozzle so that it is separated from the receiving l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com