Manufacturing process and device of bipolar plate for fuel cell

A fuel cell and manufacturing process technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as dry mixing process and unknown parameters, and achieve the effect of reducing processing costs and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A kind of preparation method of expanded graphite / resin composite bipolar plate for fuel cell, its specific steps are as follows:

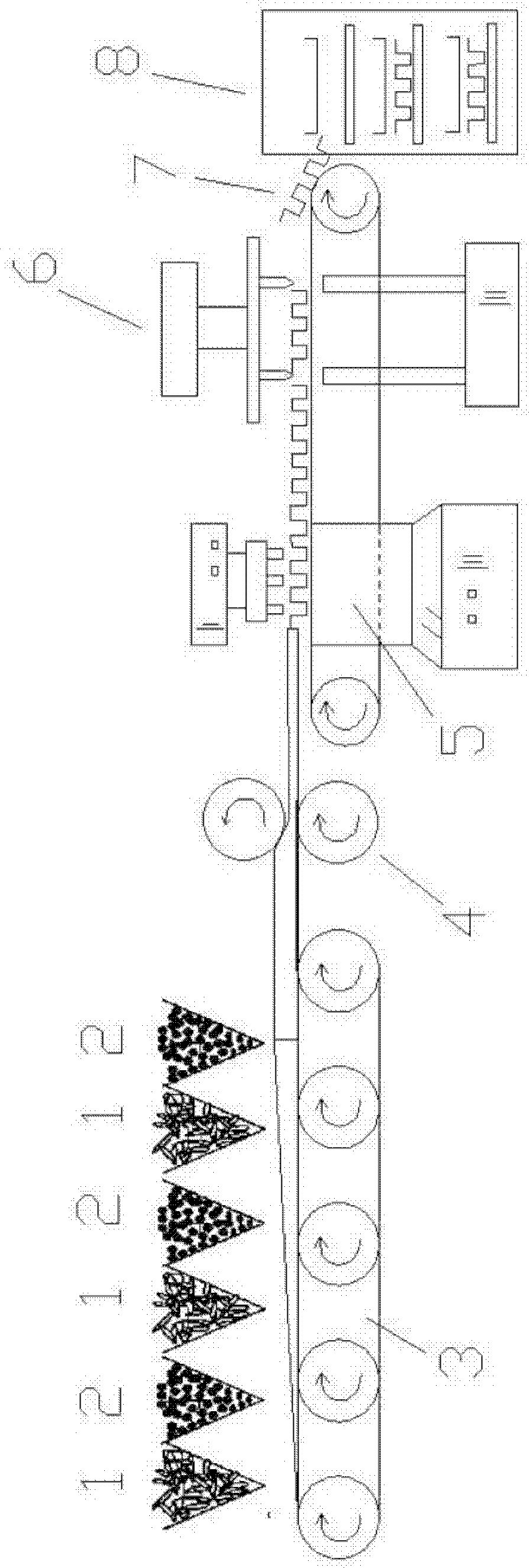

[0040] (1) The newly prepared expanded graphite with a worm-like structure is dry mixed with resin powder. Such as figure 1 As shown, the expanded graphite and resin powder are evenly sprinkled on the conveyor belt 3 through the first vibrating feeder 1 and the second vibrating feeder 2. By adjusting the first vibrating feeder 1 and the second vibrating feeder 2 Adjust the ratio of expanded graphite to resin by using parameters such as the feeding speed of the conveyor belt 3 and the walking speed of the conveyor belt 3, so that the content of the resin accounts for 10-50wt%; at the same time, control the total amount of material spilled on the conveyor belt 3 to 0.1g / sec-10g / sec; in order to make the final bipolar plate reach a certain thickness, the total amount of spilled materials can be further increased through the second group, the...

Embodiment

[0055] Add expanded graphite with an expansion ratio of 280 times and phenolic resin powder with a particle size of 30-40 μm respectively figure 1 Shown through the first vibrating feeder 1 and the second vibrating feeder 2, by adjusting the parameters such as the exciting force and the size of the discharge port, the expanded graphite and the phenolic resin are 7: 3, that is, the resin content is The ratio of 30wt% is evenly sprinkled on the conveyor belt 3, and the walking speed of the conveyor belt 3 is adjusted to be 5cm / second. At the same time, the second group and the third group of vibrating feeding units were added to further increase the total amount of spilled materials, so that the height of the expanded graphite / resin finally accumulated on the conveyor belt 3 reached about 1cm. The conveyor belt 3 sends the material to the roller press 4, and after rolling, a pre-pressed plate with a thickness of 5mm is obtained, and the density of the pre-pressed plate is 0.4g / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com