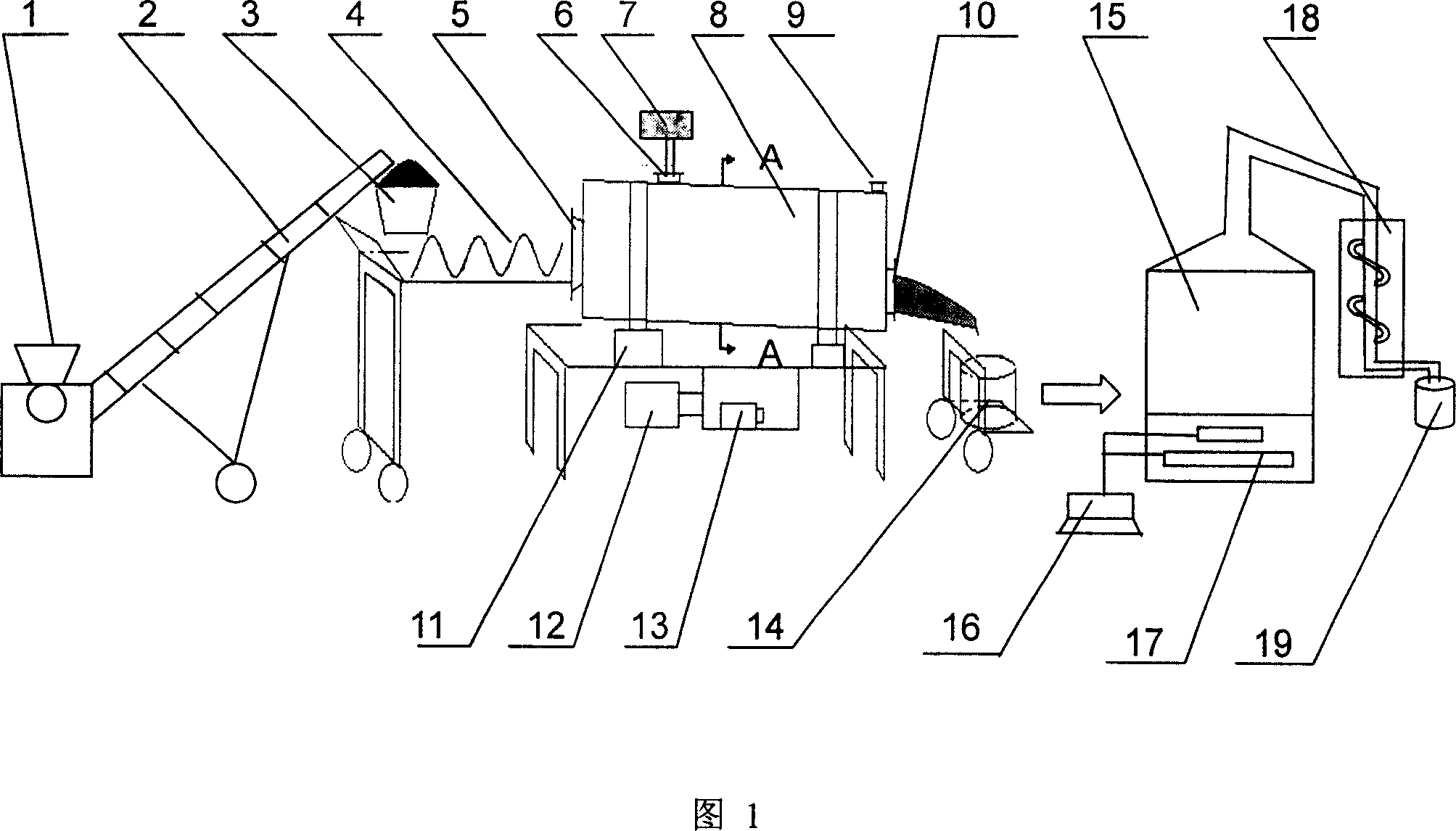

Method and system for preparing ethanol based on sweet broomcorn straw solid fermentation

A technology for solid fermentation and sweet sorghum, applied in biochemical equipment and methods, solid-phase fermentation bioreactors, fermentation, etc., can solve the problems of high pretreatment cost, shorten fermentation time, and low efficiency, and achieve improved conversion efficiency, The effect of improving utilization rate and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

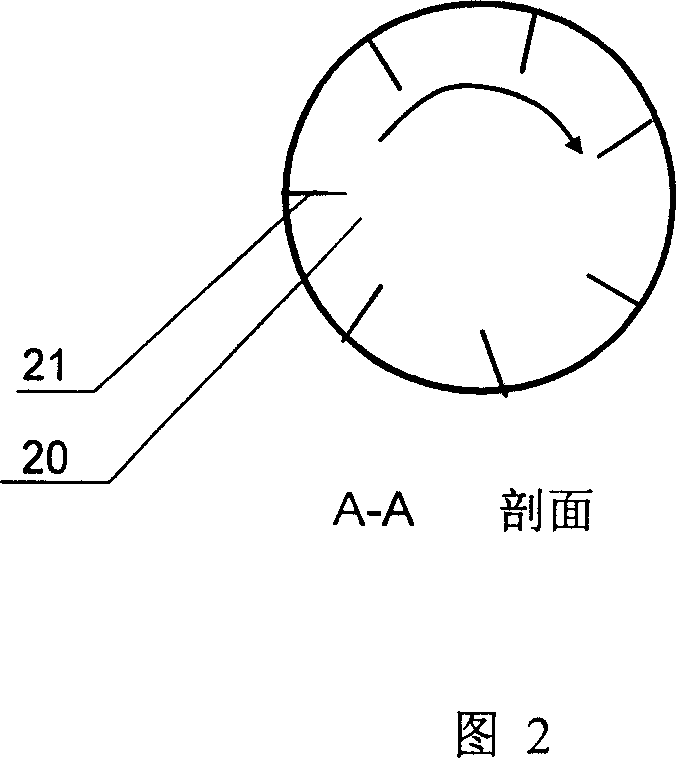

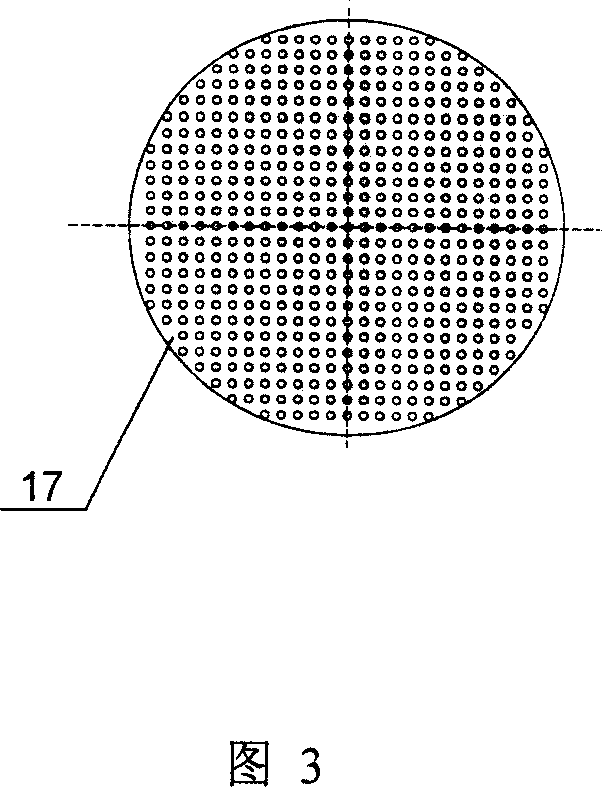

Method used

Image

Examples

Embodiment 1

[0045] Sweet sorghum stalks with a water content of 70% and a Brix of 15° (the actual stalk total sugar content is 9-10%, reducing sugar 4-5%) are used as raw materials, cut and crushed into filaments (diameter 1-2mm , length is less than 30mm), through the TSH-Sc-001 (General Microbiology Center of China Microorganism Culture Collection Management Committee, registration number, 1949, preservation date, March 6, 2007) bacterial classification directly through the present invention's selection and cultivation The solid-state fermentation is carried out in a solid fermenter, the inoculum size is 10% (V / V), the fermentation time is 48 hours, and the stirring speed is controlled at 1-20 rpm. Ethanol is obtained after distillation, and the ethanol yield is 4.23g / 100g sorghum stalk, and the conversion rate is 87.16% of the theoretical yield of ethanol; the residual total sugar content is 0.37%, and the reducing sugar content is 0.20%.

Embodiment 2

[0047] Use 1 ton of sweet sorghum stalks with a water content of 68% and a Brix of 18° (the actual total sugar content of the stalks is 13%, reducing sugar 6%) as raw materials, cut and crushed into filaments (diameter 1-2mm, length Less than 30mm), the strains of TSH-Sc-001 (General Microorganism Center of China Microbial Strain Preservation Management Committee, registration number, 1949, preservation date, March 6, 2007) bacterial classification directly on solid by the present invention's selection and cultivation The solid-state fermentation is carried out in the fermenter, the inoculum size is 10% (V / V), the fermentation time is 44hr, and the stirring speed is controlled at 1-20rpm. After distillation, 60.5 kg of ethanol is obtained, and the yield of ethanol is 6.05Kg / 100Kg 高粱秆 , the conversion rate is 90.36% of the theoretical yield of ethanol; the residual total sugar content is 0.751%, and the reducing sugar content is 0.375%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com