Conductive polymer composite fiber with skin-core structure and preparation method thereof

A conductive polymer and composite fiber technology, applied in the direction of conductive/antistatic filament manufacturing, fiber treatment, conjugated synthetic polymer artificial filament, etc., can solve the problems of incompatibility of electrical and mechanical properties, and achieve excellent electrical properties , low conductive percolation value and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of conductive polymer composite fiber described in the present invention comprises the following steps:

[0045] 1) Prepare spinning dope:

[0046] Preparation of insulating spinning stock solution: add the polymer material into the organic solution and stir until completely dissolved;

[0047] Preparation of conductive spinning stock solution: mix conductive filler with organic solvent, ultrasonic treatment, then add polymer material and mechanically stir until completely dissolved, ultrasonic again to disperse conductive filler evenly in polymer material, and finally stir and mix it again ;

[0048] 2) Transfer the prepared spinning stock solution to the syringe, extrude the insulating spinning stock solution through the inner (or outer layer) needle tube of the coaxial needle, and squeeze the conductive spinning stock solution through the outer (or inner layer) needle tube of the coaxial needle out, and then enter the coagulation bath at the ...

Embodiment 1

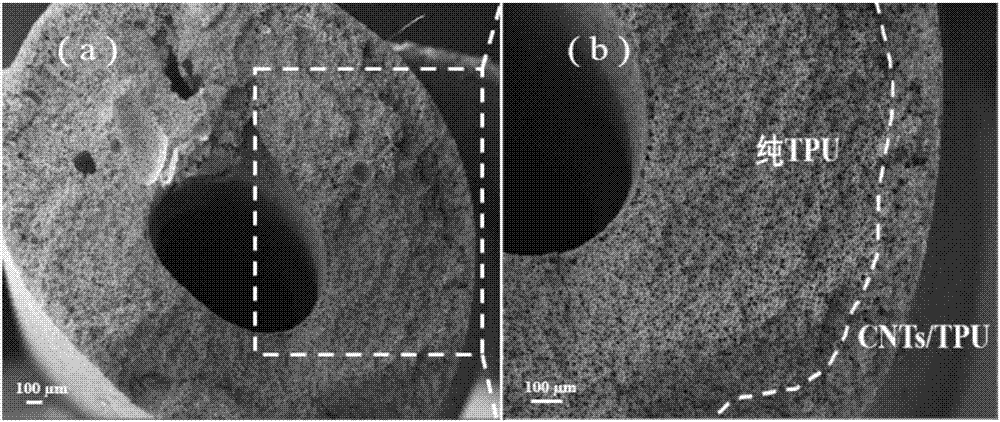

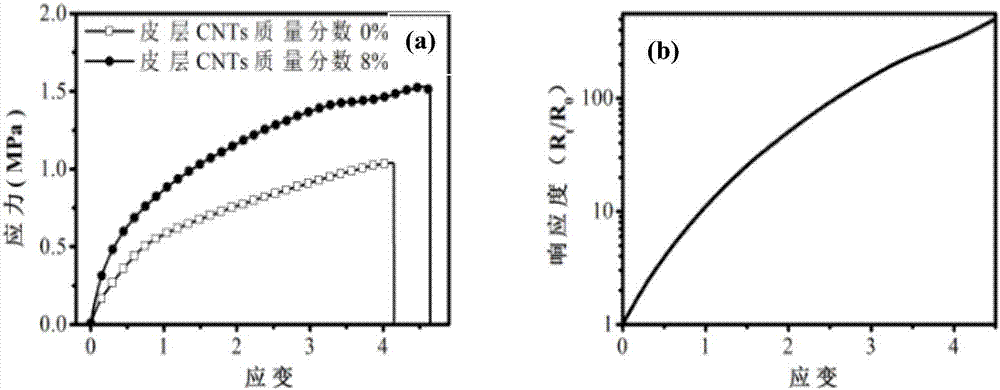

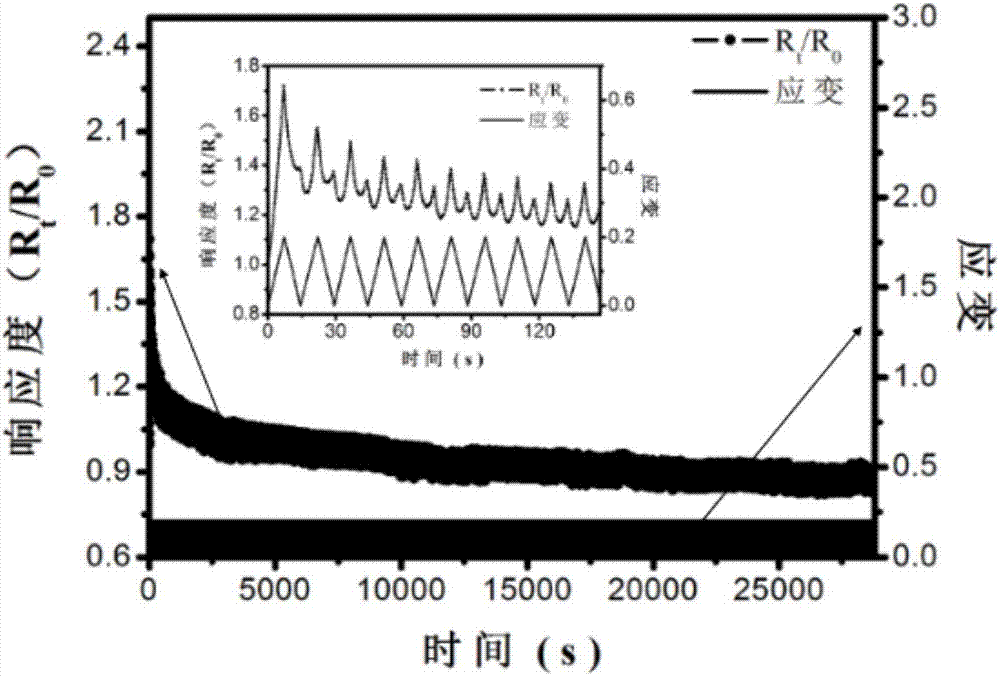

[0052] Example 1 Preparation of MWCNTs conductive polymer composite fiber with hollow, porous, skin-core structure

[0053] Concrete preparation steps are:

[0054] 1) The preparation method of the conductive spinning stock solution is: first add MWCNTs (0.43g, the mass fraction of MWCNTs is 8%, and the mass fraction of MWCNTs is the ratio of MWCNTs to the mass sum of MWCNTs and TPU) into N-N dimethylformamide (DMF ) (20mL) in an ultrasonic cleaner for 10min, then add TPU (5g) and stir with a magnetic stirrer until the TPU is completely dissolved, then put the mixed MWCNTs / TPU solution into an ultrasonic cleaner for 1h to make the MWCNTs Disperse evenly in the TPU matrix, and finally use a magnetic stirrer to stir it again for 30 minutes;

[0055] 2) The preparation method of the insulating spinning stock solution is: add TPU (5g) particles into the DMF (20ml) solution, and stir with a magnetic stirrer until the TPU is completely dissolved;

[0056] 3) The prepared spinning ...

Embodiment 2

[0063] Example 2 Preparation of hollow, porous, skin-core structure CB conductive polymer composite fiber

[0064] 1) The preparation method of the conductive spinning stock solution is as follows: first add CB (1.1g, the mass fraction of CB is 18%) to N-N dimethylformamide (DMF) (20mL) and put it in an ultrasonic cleaner for 10min, then Add TPU (5g), stir with a magnetic stirrer until the TPU is completely dissolved, then put the mixed CB / TPU solution into an ultrasonic cleaner for 1h, so that CB is evenly dispersed in the TPU matrix, and finally use a magnetic stirrer to clean it. Stir again for 30min;

[0065] 2) The preparation method of the insulating spinning stock solution is: add TPU (5g) particles into the DMF (20mL) solution, and stir with a magnetic stirrer until the TPU is completely dissolved;

[0066] 3) Transfer the prepared spinning stock solution to the syringe, extrude the insulating spinning stock solution (pure TPU solution) through the inner needle tube o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com