Production process of hydro-entangled composite non-woven fabric

A production method and non-woven technology, which are applied in the directions of non-woven fabrics, textiles and papermaking, can solve the problems of hard hand feeling, poor softness and air permeability of spunlace composite fabrics, unable to realize continuous production, etc., and achieve soft and uniform hand feel. degree of improvement and avoidance of seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

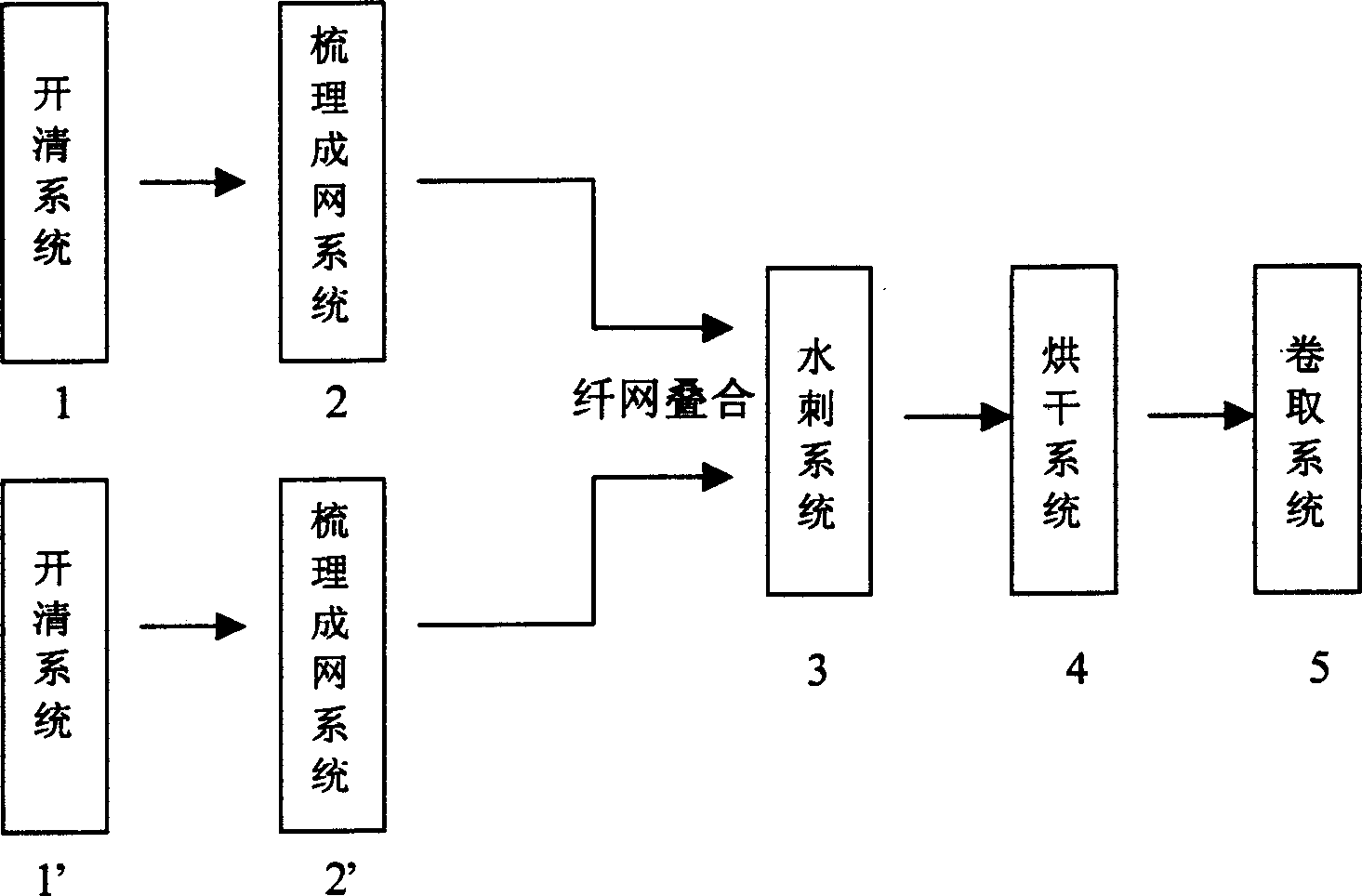

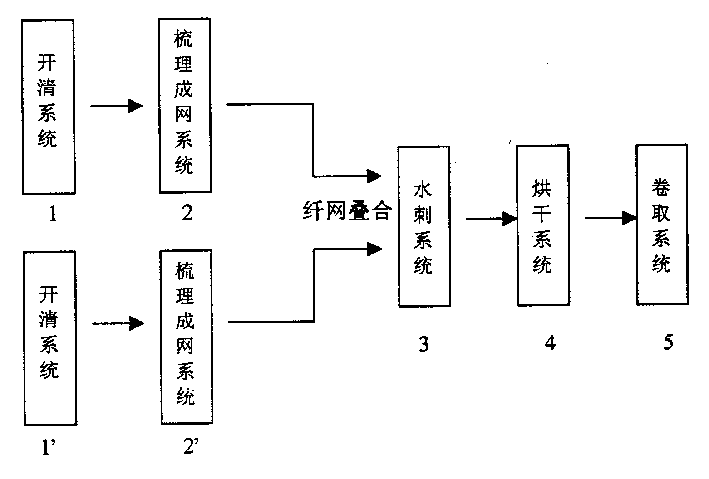

[0016] The viscose fiber is weighed, and is laid into a fiber web with a certain gram weight and strength through the opening and cleaning system 1 and the carding system 2; A web with a certain weight and strength. Then, the fiber web is laminated with the fiber web online, and after 2 to 8 high-speed fine water jets with a water pressure of 10 bar to 160 bar (that is, the spunlace system 3), the fibers are entangled and reinforced. It passes through the drying system 4 at a temperature of 160°C, and finally passes through the coiling system 5 to make a spunlace composite non-woven fabric.

Embodiment 2

[0018] The antibacterial fiber is weighed, and it is laid into a fiber web with a certain gram weight and strength through the opening and cleaning system 1 and carding system 2; the viscose fiber and polyester fiber are weighed according to a certain mixing ratio, and the opening and cleaning system 1', carding The web forming system 2' paves a fiber web with a certain grammage and strength. Then, the fiber web is laminated with the fiber web online, and after 2 to 8 high-speed fine water jets with a water pressure of 10 bar to 160 bar (that is, the spunlace system 3), the fibers are entangled and reinforced. It passes through the drying system 4 at a temperature of 160°C, and finally passes through the coiling system 5 to make a spunlace composite non-woven fabric.

Embodiment 3

[0020] The chitin fiber is weighed and laid into a fiber web with a certain gram weight and strength through the opening and cleaning system 1 and the carding system 2; the viscose fiber is weighed and laid through the opening and cleaning system 1' and the carding system 2' A fiber net with a certain weight and strength. Then, the fiber web is laminated with the fiber web online, and after 2 to 8 high-speed fine water jets with a water pressure of 10 bar to 160 bar (that is, the spunlace system 3), the fibers are entangled and reinforced. It passes through the drying system 4 at a temperature of 160°C, and finally passes through the coiling system 5 to make a spunlace composite non-woven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com