Method for preparing nano material by flame combustion

A technology of nanomaterials and flame combustion, applied in chemical instruments and methods, oxide/hydroxide preparation, inorganic chemistry, etc., can solve the problem of increasing the complexity and uncontrollability of the reaction process, reducing the controllability of the reaction process, Complicated issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The invention is also suitable for the preparation of water-soluble carbon nanotubes, wherein the length of the obtained carbon tube is 10 nanometers to 10 micrometers. The heads or tubes of the above-mentioned carbon tubes usually contain metal oxide particles, but after treatment with concentrated hydrochloric acid, the metal oxide particles can be removed to obtain carbon nanotubes that can be dispersed in water. The solution formed by dispersing carbon nanotubes in water has excellent colloidal stability, and no carbon tubes will precipitate out within half a year.

[0054] The starting materials used in the present invention are cheap and easy to obtain, the preparation process of nano materials is simple and the nano materials can be produced continuously, the operation is simple, and no complicated equipment is required. The organic solution of the soluble metal compound precursor is directly burned in the air, and Using different soluble metal compound precursors or...

Embodiment 1

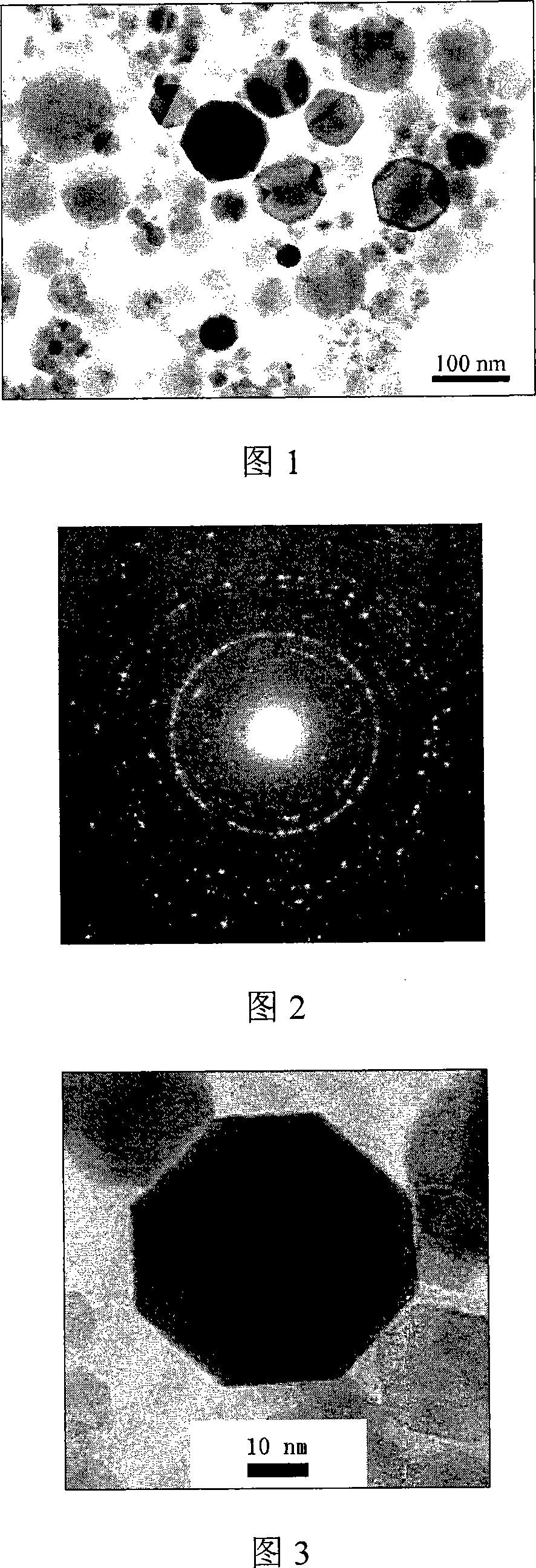

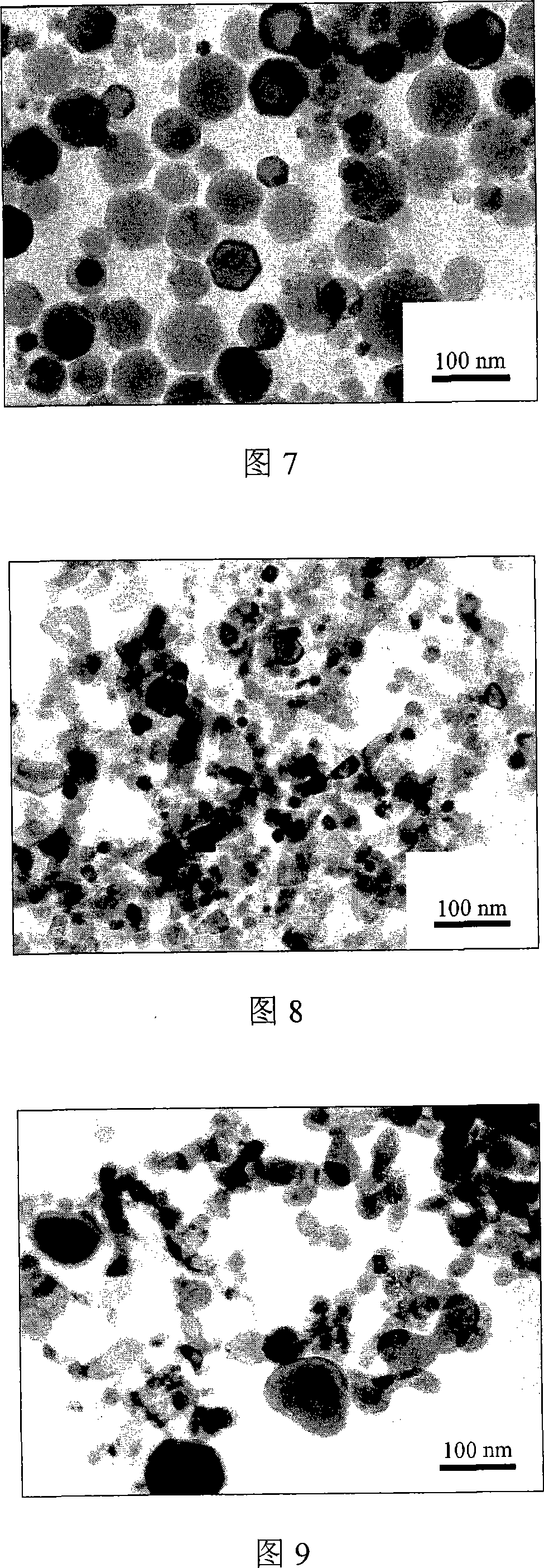

[0058] Weigh 0.88 g of iron triacetylacetonate and dissolve it in 50 mL of absolute ethanol. The solution was transferred to an open container, and after ignition, the flame state reached stability within about 1 minute. After the flame state is stable, use a glass sheet with a water film at the tip of the outer flame to collect the powdery substance continuously. When the liquid level drops and the flame position drops, the relative position of the receiving device can be adjusted appropriately so that it is still receiving at the above-mentioned position. After the solution is completely burned, the collected brown-red powder is ultrasonically dispersed with 20 mL of deionized water, and the precipitate is collected by centrifugal separation (4000 revolutions / min), and the precipitate is washed with deionized water 3 Then, finally, the precipitate is mixed with deionized water and ultrasonically dispersed to obtain an aqueous dispersion of the product. X-ray diffraction results ...

Embodiment 2

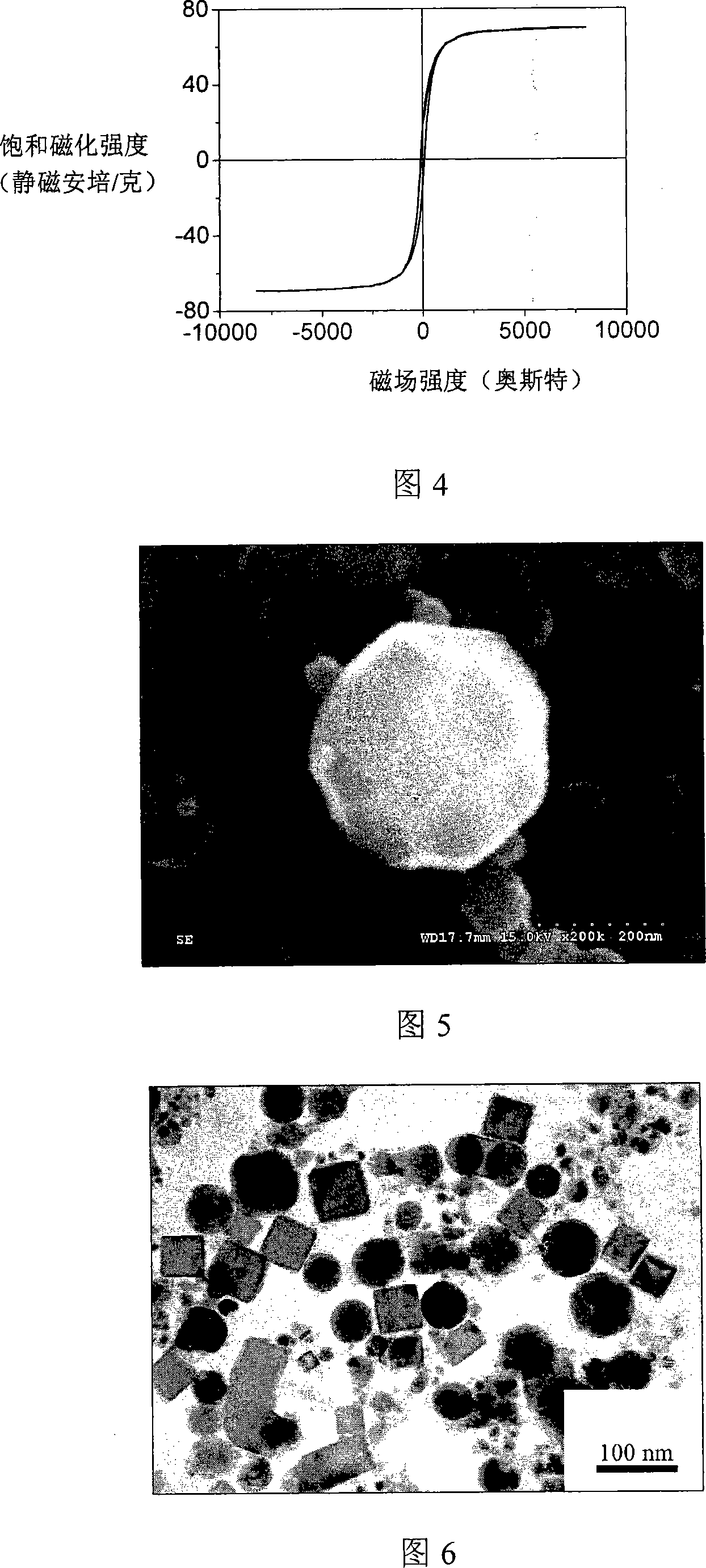

[0060] Weigh 8.83 g of iron triacetylacetonate and dissolve it in a mixed solvent of 30 mL of methanol and 20 mL of N-vinyl-2-pyrrolidone. Except that the collection time is 5-60 minutes after ignition, the other operations are the same as in Example 1. Γ-Fe obtained 2 O 3 Nanoparticles are ferromagnetic, and their saturation magnetization is 70.4 magnetostatic amperes / g, which is close to the saturation magnetization value of bulk materials; the particle size is 20-300 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com