Processing system and technology for natural fibrous composite felt used for automotive trim plate core layer

A technology of automotive interior panels and natural fibers, which is applied in textiles, papermaking, adhesives, non-woven fabrics, etc., can solve the problems of unstable product quality, low degree of automation, and high production costs, and improve the degree of production automation and product quality Stability, low cost, effect of improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

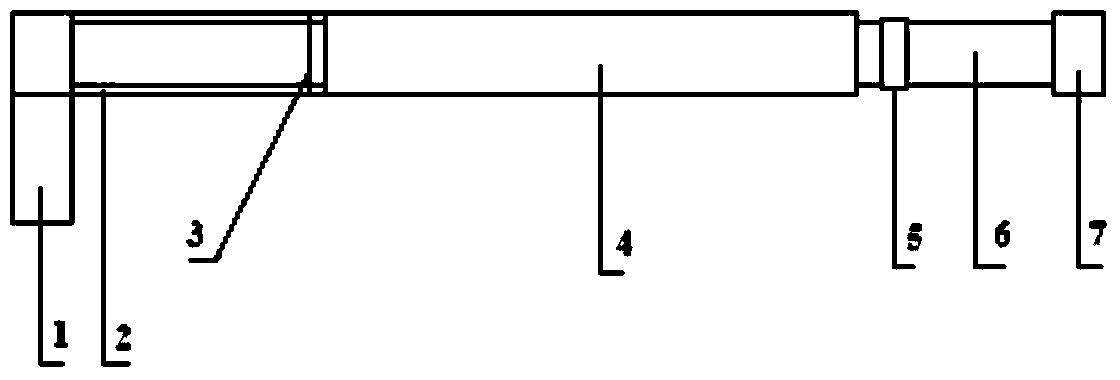

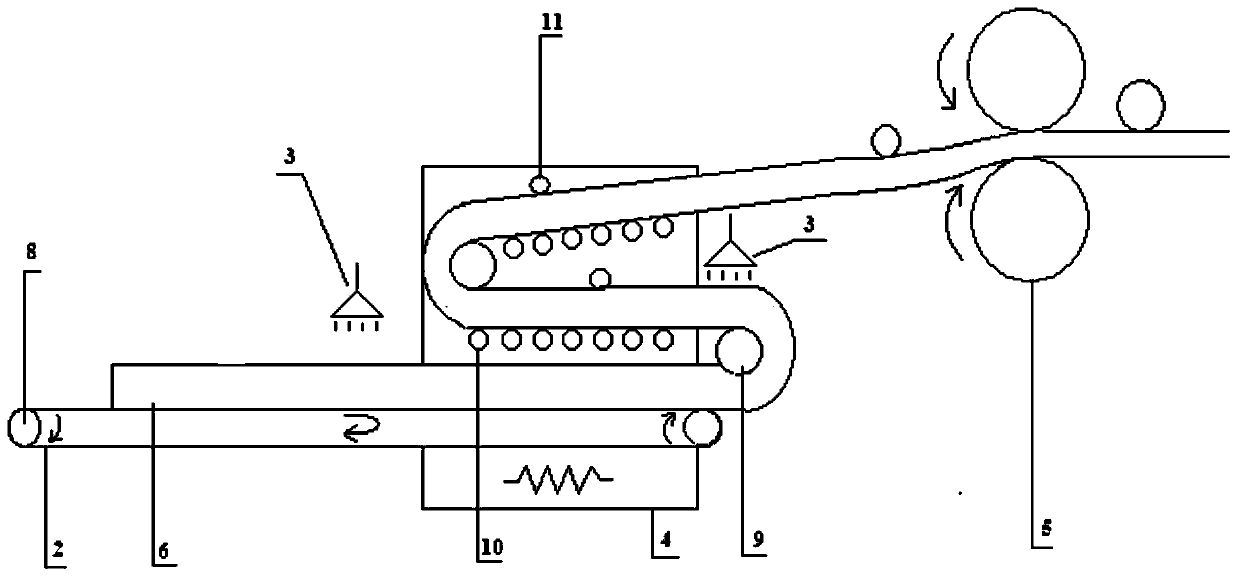

[0027] Such as figure 1 As shown, the processing system of natural fiber composite felt for the core layer of automobile interior trim includes a fiber web generating device 1, and the fiber web generating device 1 is connected to an oven 4 through a bottom curtain 2, and the bottom curtain 2 is provided with a driving structure 8, and the oven 4 The fiber web that comes out is extended to the winding device 7 through the hot-pressing device, and the oven 4 is provided with a fabric guide roller 9 and a support delivery roller 10 that wind the fiber web into an S shape. The hot-pressing device is a pair of heating and pressing The rotating roller 5, the fiber web forming device 1 includes an opening device, a carding device and a web laying device connected in sequence.

[0028] The opening device is an opening machine, the carding device is a carding machine, and the web laying device is a web laying machine. The outlet of the opening machine is connected to the cotton mixing...

Embodiment 2

[0035] Such asfigure 1 , figure 2 As shown, the processing system of natural fiber composite felt for the core layer of automobile interior trim includes a fiber web generating device 1, and the fiber web generating device 1 is connected to an oven 4 through a bottom curtain 2, and the bottom curtain 2 is provided with a driving structure 8, and the oven 4 The fiber web that comes out is extended to the winding device 7 through the hot-pressing device, and the oven 4 is provided with a fabric guide roller 9 and a support delivery roller 10 that wind the fiber web into an S shape. The hot-pressing device is a pair of heating and pressing The rotating roller 5, the fiber web forming device 1 includes an opening device, a carding device and a web laying device connected in sequence.

[0036] The opening device is an opening machine, the carding device is a carding machine, and the web laying device is a web laying machine. The outlet of the opening machine is connected to the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com