Laser code spraying, detecting and sorting all-in-one machine and laser code spraying, detecting and sorting method

A technology of laser coding and all-in-one machine, applied in the field of instruments, can solve the problems of low performance, the sorting machine cannot be used for production laser coding, and the laser coding equipment cannot be used for sorting and sorting efficiency, etc., to improve stability and reduce Production link, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

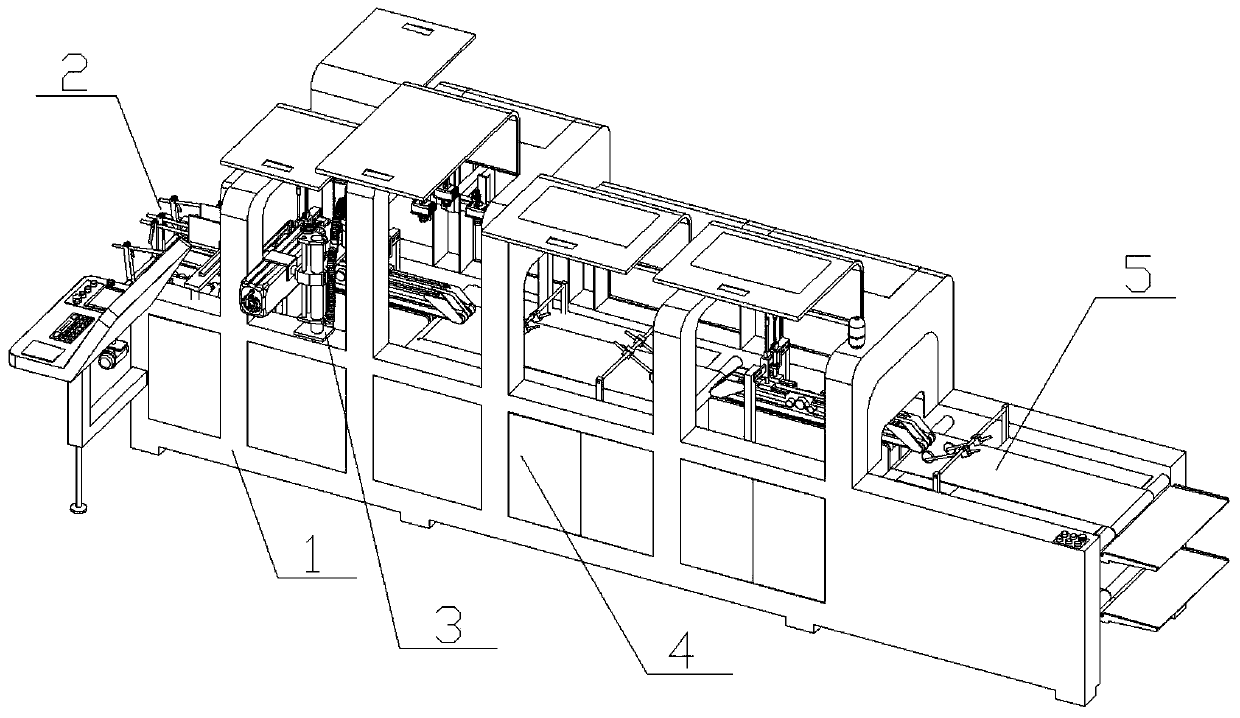

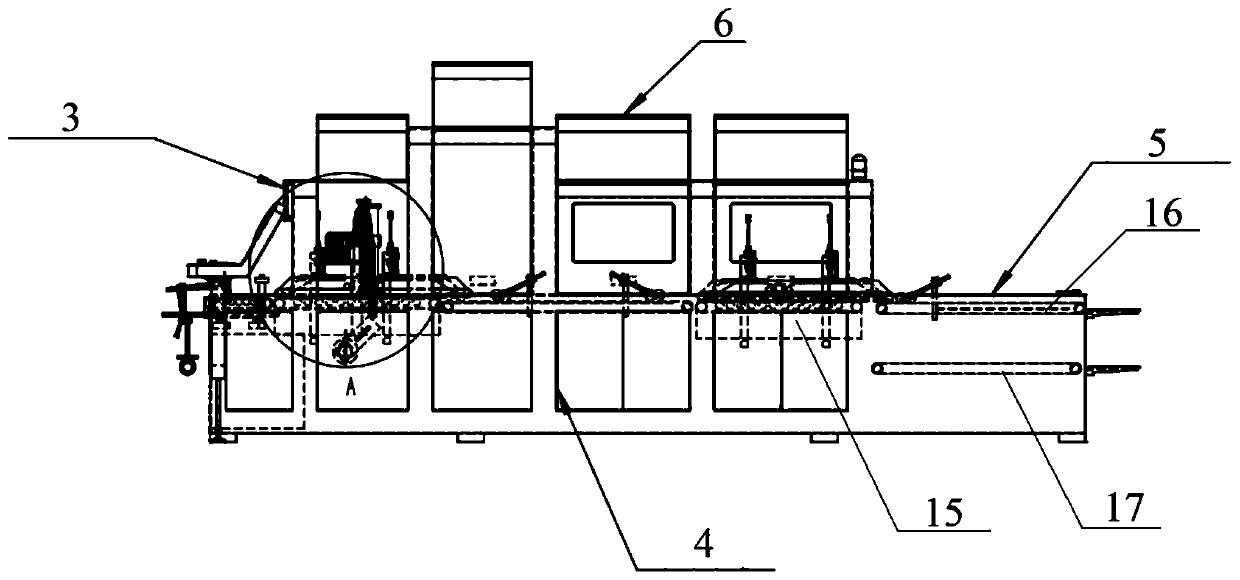

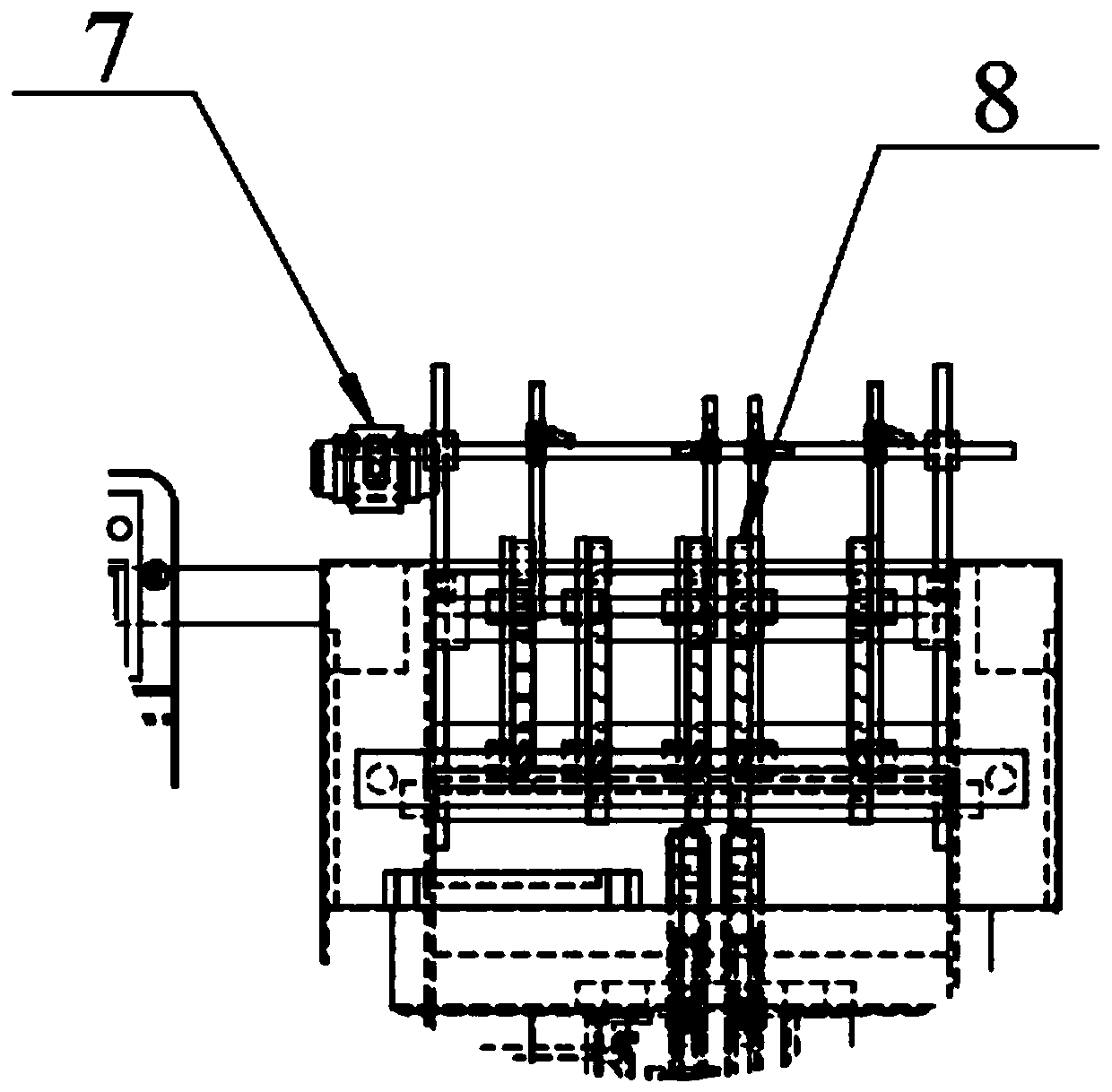

[0044] Attached below Figure 1-7 , to describe in detail the specific embodiments of the integrated laser marking, detection and sorting machine and its working method provided by the present invention.

[0045] See attached Figure 1-5 As shown, this embodiment provides a laser coding, detection and sorting integrated machine for coding paper packaging bags. The information in the code package can include numbers, English letters, or numbers plus English letters, etc. After laser coding, the two-dimensional code is marked on the packaging bag.

[0046] The all-in-one machine specifically includes a support 1, a paper feeding part 2, a laser code sending control system, a laser coding device 3, a laser coding control system, a sorting device 4, a sorting control system, a paper delivery part 5 and a general control system. Among them, the paper feeding part 2 is arranged at the front end of the support 1, and the laser marking device 3, the sorting device 4 and the delivery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com