Control method of rotary drum type cut-tobacco drier three-level regulation

A control method and technology for a drying machine, which are applied in the fields of tobacco preparation, application, and tobacco, can solve the problems of temperature fluctuation of the drying machine cylinder wall and the influence of product sensory quality stability, and achieve the effect of improving product quality stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

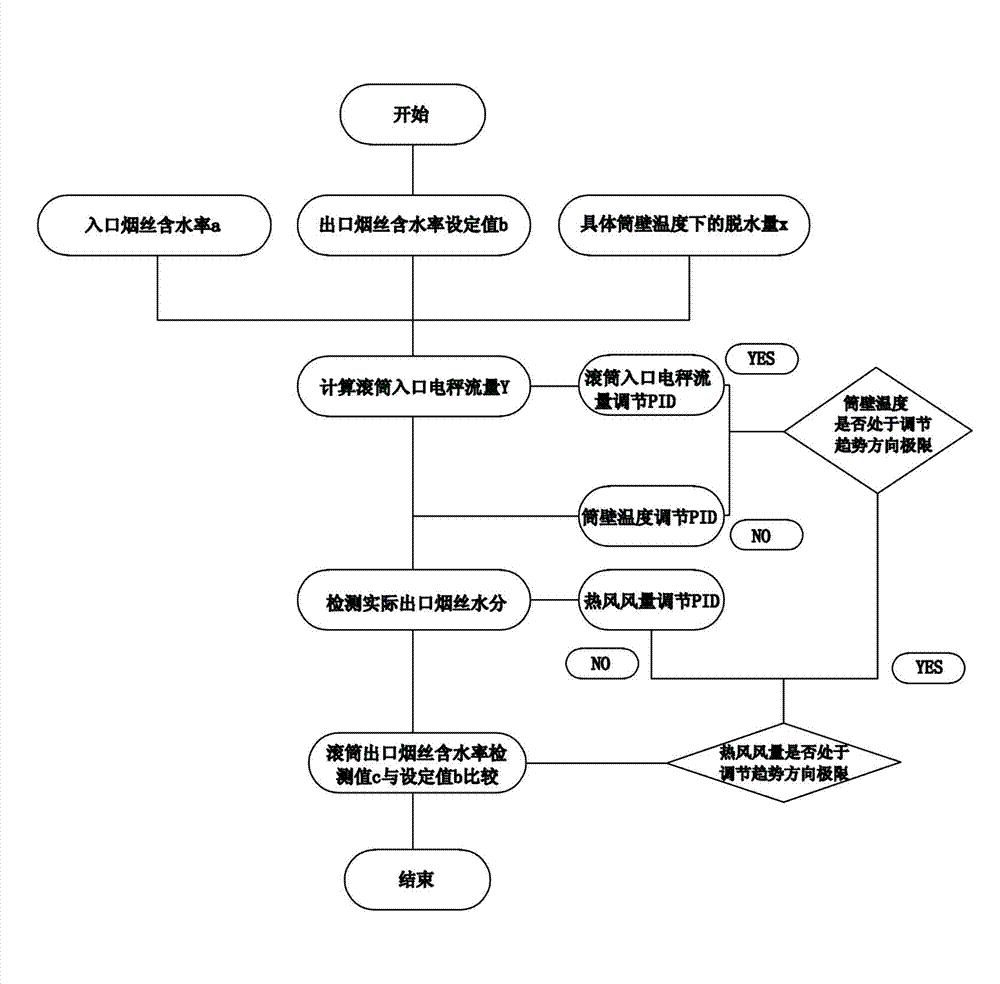

[0021] Now combined figure 1 The examples illustrate the invention.

[0022] The flow rate of cut tobacco designed for a drum type tobacco dryer is 2000kg / h, and the barrel wall temperature processing range of a certain brand of tobacco tobacco dryer is 116℃ to 120℃, and the reasonable range of hot air flow is 500㎡ / h to 2000㎡ / h. According to the drum drying characteristics, after establishing the regression equation based on the historical data of the drum dryer, the correlation between the dehydration amount corresponding to the drum wall temperature can be calculated as the following formula: Y=1.9* X-86.2 (X is the drum wall temperature, Y is the amount of dehydration). The above formula Y = 1.9* X-86.2 in 1.9 and 86.2 is the result of establishing a regression equation based on the historical data of the tumble dryer.

[0023] The preset barrel wall temperature value is 118℃, the hot air volume is 1200 ㎡ / h, the moisture content of the cut tobacco at the inlet of the drum is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com