Split type water jacket with diversion water tank and assembly method

A split-type, water-jacketed technology, applied in the field of metallurgical continuous casting, can solve problems such as inability to have uniform water gaps, uneven water gaps, and deviation between the center of the circle and the center of the casting machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

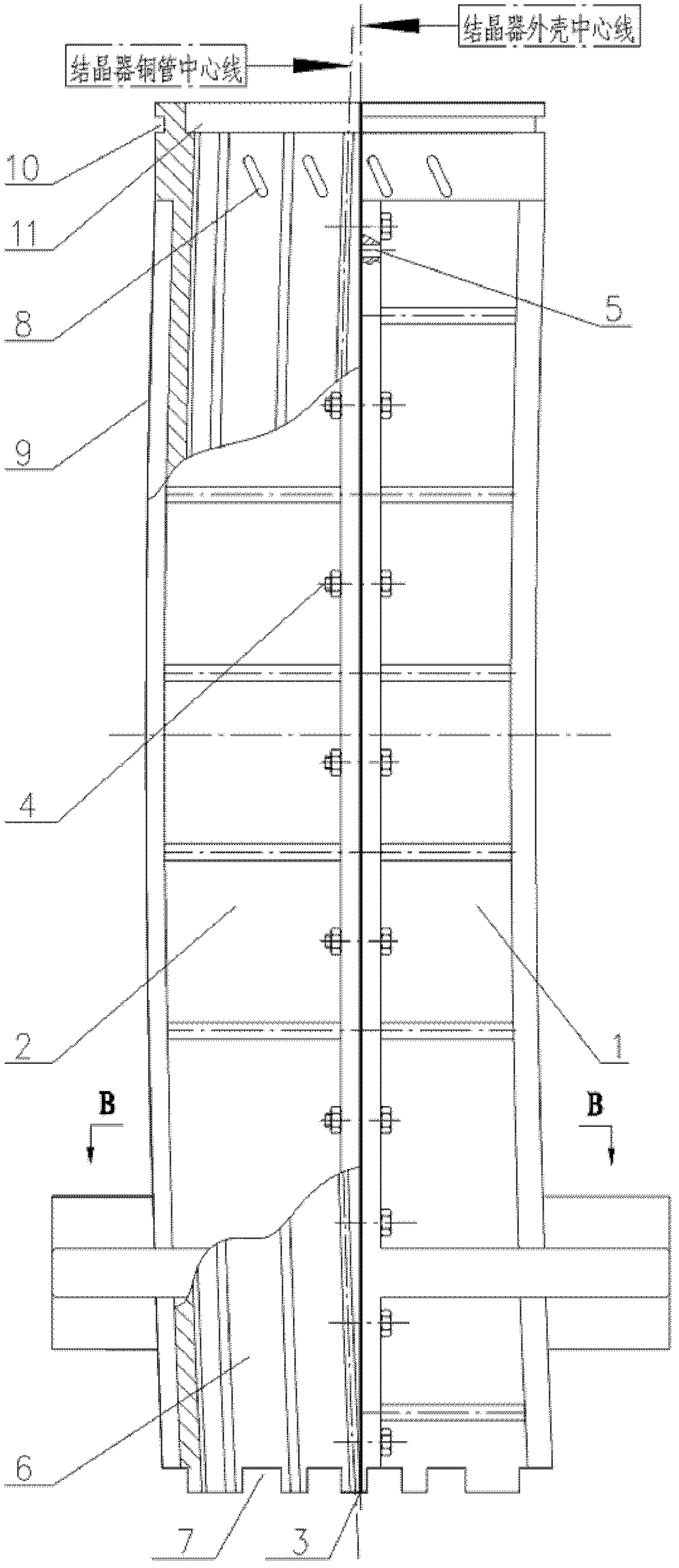

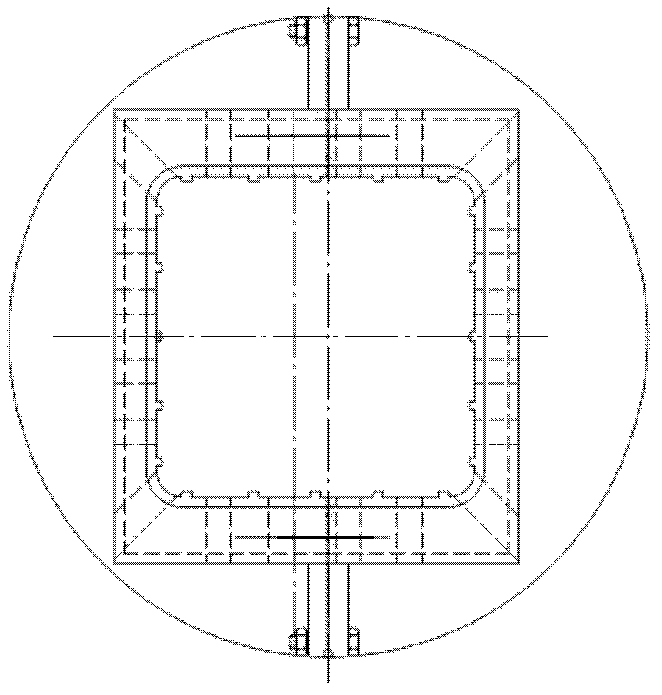

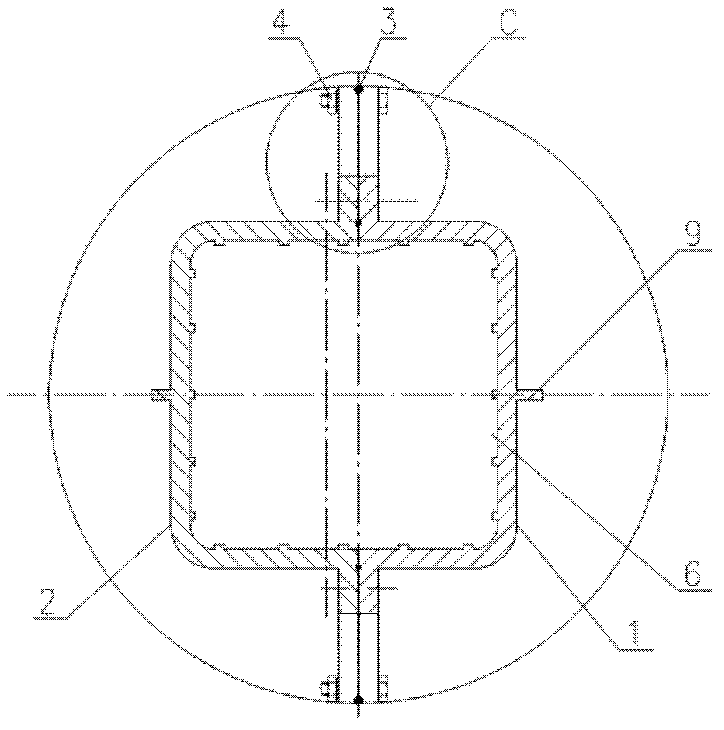

[0020] The following further describes the embodiments of the present invention with reference to the accompanying drawings. The symbols in the accompanying drawings: figure 1 ~ Attached Figure 4 Middle, 1—inner arc half water jacket, 2—outer arc half water jacket, 3—seals, 4—fasteners, 5—positioning pins; 6—sink, 7—water inlet, 8—water outlet, 9— Ribs. 10-card slot, 11-positioning step; attached Figure 7 ~ Attached Figure 8 Middle, 12—seal Ⅰ, 13—mold cylinder, 14—water jacket, 15—mold copper tube, 16—fasteners, 17—top cover, 18—snap ring I, 19—seal II, 20—seal Ⅲ, 21—snap ring Ⅱ, 22—seal Ⅳ.

[0021] Reference attached figure 1 ~ Attached Figure 4 And attached Figure 7 And Figure 8 , The split water jacket 14 with diversion water tank of the present invention is the diversion water jacket 14 that surrounds the copper tube 15 of the mold, and includes an inner arc half water jacket 1, an outer arc half water jacket 2, a seal, and a fastener And positioning pin 5; the gap b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com