Sunflower module assembling system based on visual guidance

A visual guidance and assembly system technology, applied in image data processing, instruments, metal processing, etc., can solve the problems of high assembly cost, low pass rate, and large heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] As an implementation, the purpose of the present invention is to apply machine vision technology to the large-scale personalized production and assembly of Sunflower modules, so as to realize the assembly detection of modules, intelligentization and automation of packaging.

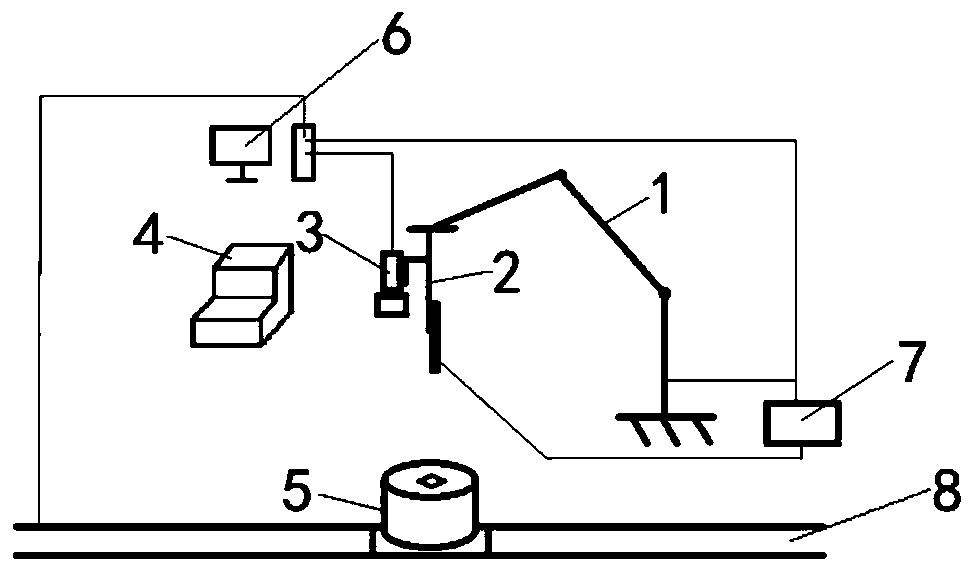

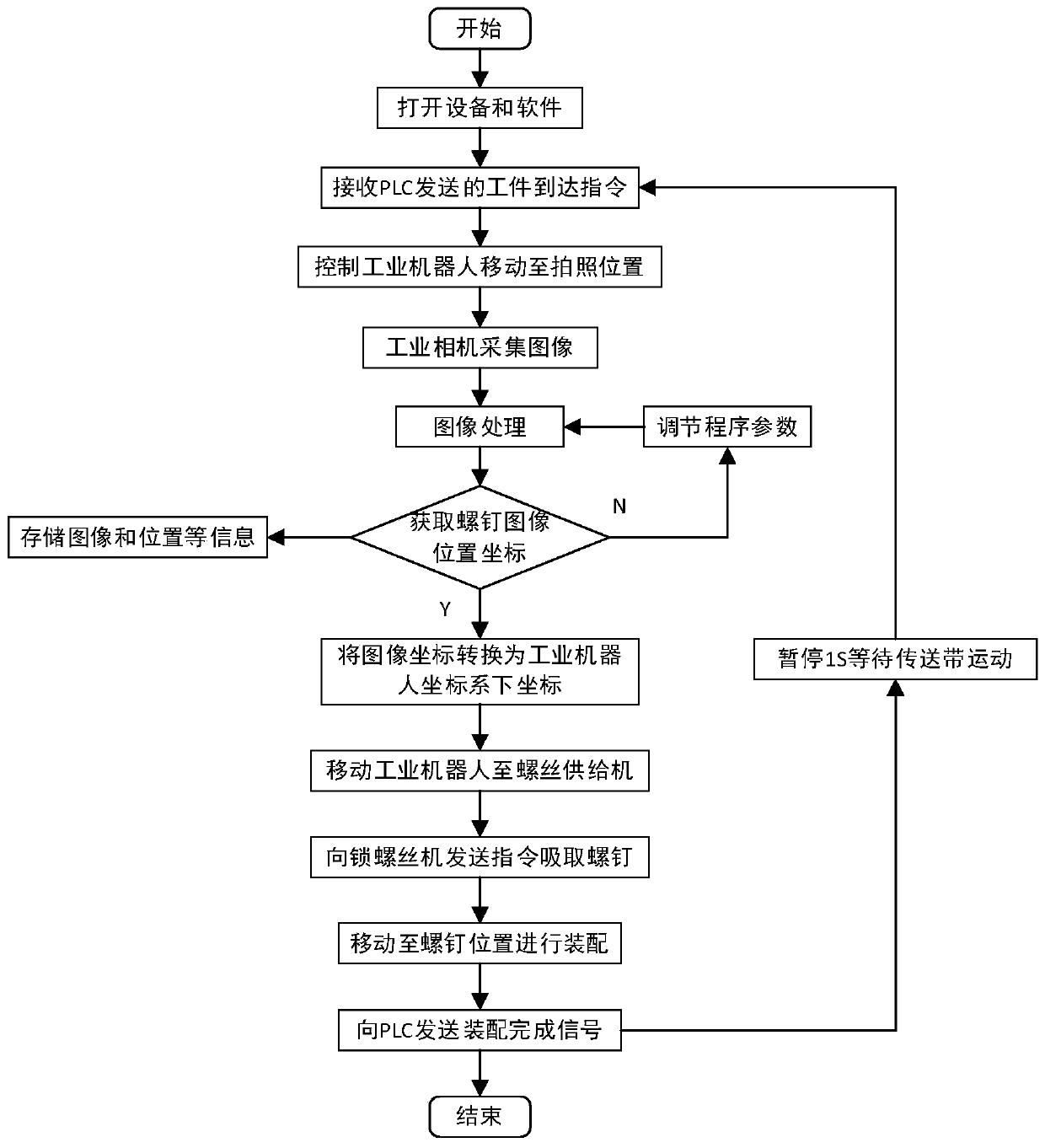

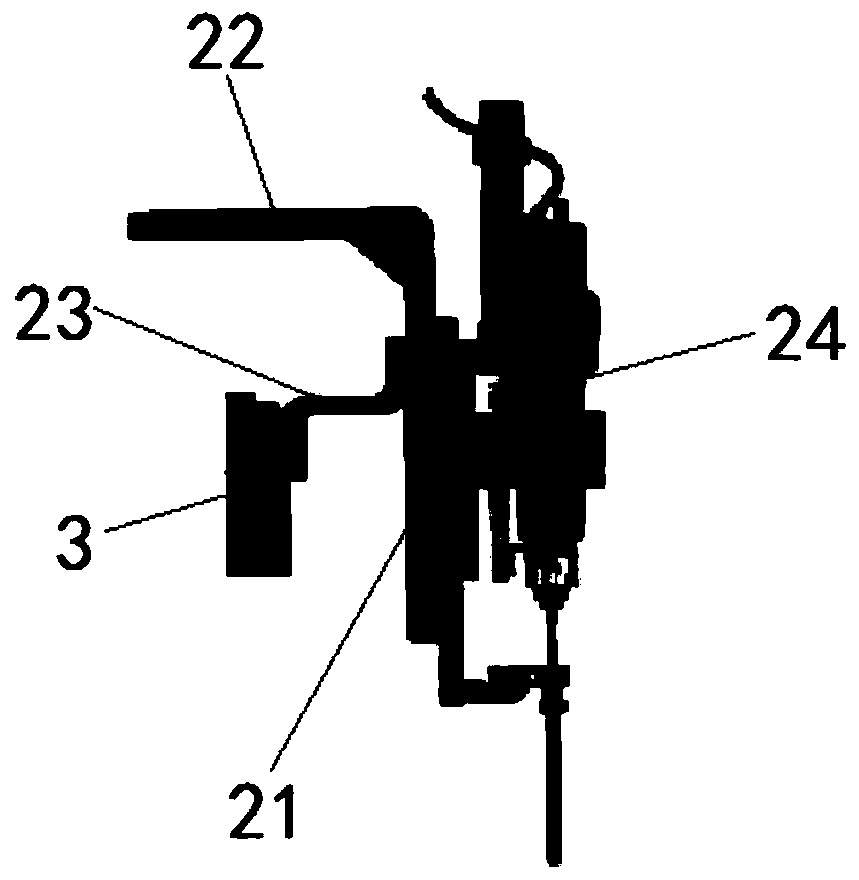

[0120] Such as figure 1 As shown, a vision-guided module assembly system includes a manipulator 1, an industrial camera 3, a tooling platform, a data processor 6, a sensor, a conveyor belt 8, a module tooling position 5, a screw supply machine 4, and a sunflower module , programmable logic controller (PLC), manipulator 1, control cabinet 7; It is characterized in that, manipulator 1 comprises manipulator 1 and end effector 2, and end effector 2 is assembled with industrial camera 3 and electric locking screw machine; End effector 2 Below is the conveyor belt 8, the conveyor belt 8 is placed on the tooling platform, the conveyor belt 8 is located in the middle of the tooling platform, there is a mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com