X80 pipeline steel plate with low yield ratio and high toughness and manufacturing method thereof

A technology with low yield ratio and high toughness, applied in the field of X80 pipeline steel plate and its manufacturing, can solve the problems of low yield ratio, uneven performance, low production efficiency, etc., achieve high toughness, low yield ratio, and improve production efficiency and product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

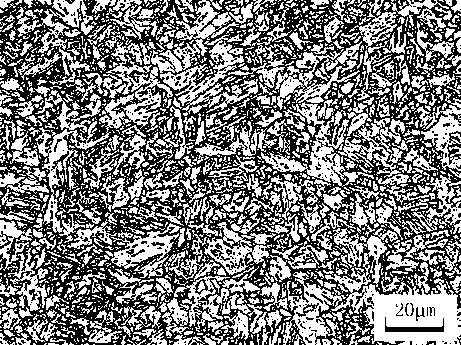

Embodiment 1

[0040] A low yield ratio high toughness X80 pipeline steel plate, its chemical composition and weight percentage are: C: 0.036%, Si: 0.28%, Mn: 1.89%, P: 0.010%, S: 0.0011%, Ni: 0.20%, Mo: 0.18%, Cr: 0.34%, Cu: 0.16%, Nb: 0.048%, Ti: 0.016%, Al: 0.048%, N: 0.0066%, and the balance is Fe and unavoidable inclusions.

[0041] Production process steps:

[0042] 1) Smelting and continuous casting into billets;

[0043] 2) Heating the billet, controlling the heating temperature at 1100-1105°C; and descaling with high-pressure water;

[0044] 3) Using TMCP process:

[0045] a. Rough rolling: the starting temperature is 1062°C, the reduction rate of each pass of rough rolling is ≥10%, the end temperature of rough rolling is 1030°C, and the cumulative rough rolling reduction rate is 60%;

[0046] b. Carry out finish rolling, the start rolling temperature is 890°C, the finish temperature is 823°C, the cumulative reduction rate of finish rolling is 80%; the thickness of the steel plat...

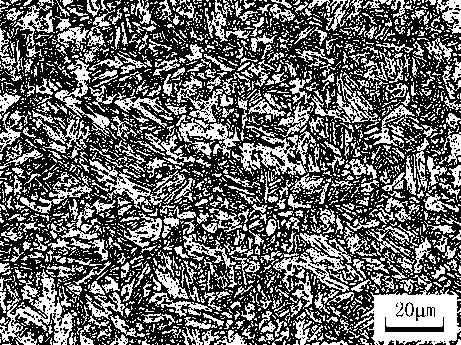

Embodiment 2

[0052] A low yield ratio high toughness X80 pipeline steel plate, its chemical composition and weight percentage are: C: 0.041%, Si: 0.22%, Mn: 1.83%, P: 0.012%, S: 0.0013%, Ni: 0.15%, Mo: 0.13%, Cr: 0.50%, Cu: 0.24%, Nb: 0.055%, Ti: 0.022%, Al: 0.021%, N: 0.0073%, and the balance is Fe and unavoidable inclusions.

[0053] Production process steps:

[0054] 1) Smelting and continuous casting into billets;

[0055] 2) Heating the billet, controlling the heating temperature at 1100-1105°C; and descaling with high-pressure water;

[0056] 3) Using TMCP process:

[0057] a. Rough rolling: the starting temperature is 1062°C, the reduction rate of each rough rolling pass is not less than 10%, the rough rolling end temperature is 1030°C, and the rough rolling cumulative reduction rate is 60%;

[0058] b. Carry out finish rolling, the start rolling temperature is 890°C, the finish temperature is 823°C, the cumulative reduction rate of finish rolling is 80%; the thickness of the ste...

Embodiment 3

[0064] A low yield ratio high toughness X80 pipeline steel plate, its chemical composition and weight percentage are: C: 0.047%, Si: 0.38%, Mn: 1.74%, P: 0.009%, S: 0.0010%, Ni: 0.40%, Mo: 0.10%, Cr: 0.30%, Cu: 0.19%, Nb: 0.042%, Ti: 0.011%, Al: 0.028%, N: 0.0057%, and the balance is Fe and unavoidable inclusions.

[0065] Production process steps:

[0066] 1) Smelting and continuous casting into billets;

[0067] 2) Heating the billet, controlling the heating temperature at 1120-1125°C; and descaling with high-pressure water;

[0068] 3) Using TMCP process:

[0069] a. Rough rolling: the starting temperature is 1088°C, the reduction rate of each pass of rough rolling is not less than 10%, the finishing temperature of rough rolling is 1066°C, and the cumulative reduction rate of rough rolling is 68%;

[0070] b. Carry out finish rolling, the start rolling temperature is 930°C, the finish temperature is 843°C, the cumulative reduction rate of finish rolling is 78.1%; the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com