Process for enhancing denitrogenation of membrane bioreactor by anaerobic fermentation acid production

A bioreactor and anaerobic fermentation technology, which is applied in the field of anaerobic fermentation and acid production to strengthen membrane-bioreactor denitrification treatment process, can solve the problems of affecting denitrification effect and insufficient carbon source in anoxic section, and achieve enhanced denitrification. Nitrogen effect, reduction of sludge discharge, effect of reduction and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

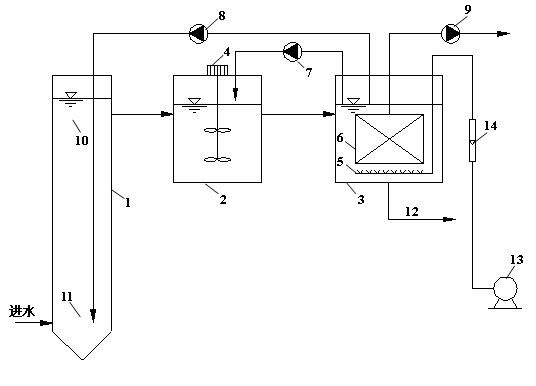

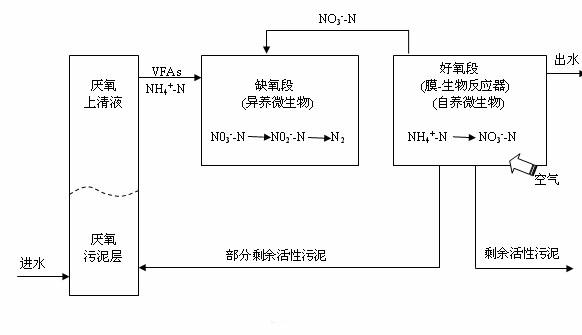

[0027] Using this sewage treatment process and device to treat typical urban domestic sewage, the influent COD concentration is 461±287 mg / L, the total nitrogen concentration is 44.6±15.1 mg / L, the total phosphorus concentration is 6.3±2.4 mg / L, and the ammonia nitrogen concentration is 28.0±7.5 mg / L. Reactor membrane module flux 20 L / (m 2 h), the total hydraulic retention time of the system is 7.1 h, and the sludge age is 100 days. Among them, the hydraulic retention time of the denitrification process is 5.1 h, the sludge age of nitrifying bacteria is 17 days, the return flow rate of the first return pump 7 is 200%, and the second return pump 8 The return flow rate is 1.3 L / d. The sludge concentration in the aerobic section of the device is MLSS=13.2±2.1 g / L, the COD concentration in membrane effluent is 18±5 mg / L, the total nitrogen concentration is 7.2±2.9 mg / L, and the total phosphorus concentration is 2.2±1.2 mg / L L, the concentration of ammonia nitrogen is 0.3±0.1mg / L...

Embodiment 2

[0029] Using this sewage treatment process and device to treat domestic sewage in a rural area, the influent COD concentration is 245±105 mg / L, the total nitrogen concentration is 47.4±14.5 mg / L, the total phosphorus concentration is 7.7±3.9 mg / L, and the ammonia nitrogen concentration It was 35.0±12.6 mg / L. Reactor membrane module flux 18 L / (m 2 h), the total hydraulic retention time of the system is 7.9 h, and the sludge age is 100 days. Among them, the hydraulic retention time of the denitrification process is 5.7 h, the sludge age of nitrifying bacteria is 15 days, the return flow of the first return pump 7 is 200%, and the return flow 2 is 1.5 L / d. The sludge concentration in the aerobic section of the device is MLSS=12.5±3.2 g / L, the COD concentration in membrane effluent is 18±6 mg / L, the total nitrogen concentration is 8.3±2.5 mg / L, and the total phosphorus concentration is 3.0±1.6 mg / L L, the concentration of ammonia nitrogen is 0.5±0.15 mg / L, and the removal rates ...

Embodiment 3

[0031] Using this sewage treatment process and device to treat low-carbon domestic sewage in a southern city, the influent COD concentration is 150±36 mg / L, BOD concentration is 60±15 mg / L, SS is 40 mg / L, and the total nitrogen concentration is 42.3±10.4 mg / L, ammonia nitrogen concentration was 30.2±6.5 mg / L. Reactor membrane module flux 15 L / (m 2 h), the total hydraulic retention time of the system is 9.5 h, and the sludge age is 128 days. Among them, the hydraulic retention time of the denitrification process is 6.8 h, and the sludge age of nitrifying bacteria is 15 days; the return flow rate of the first return pump 7 is 200%, and the second return pump 8 The return flow rate is 1.5 L / d. The sludge concentration in the aerobic section of the device is MLSS=10.5±3.1 g / L, the COD concentration in membrane effluent is 16±5 mg / L, the total nitrogen concentration is 10.0±2.3 mg / L, and the ammonia nitrogen concentration is 0.5±0.2 mg / L. The removal rates of COD, total nitrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com