Hazardous waste incineration flue gas purification system and process

A technology for hazardous waste and flue gas incineration, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problem of failure to meet standards and local requirements, single purification technology for hazardous waste incineration flue gas, and limited removal efficiency of nitrogen oxides and other problems, to achieve the effect of protecting the cloth bag, improving the absorption efficiency and reducing the pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

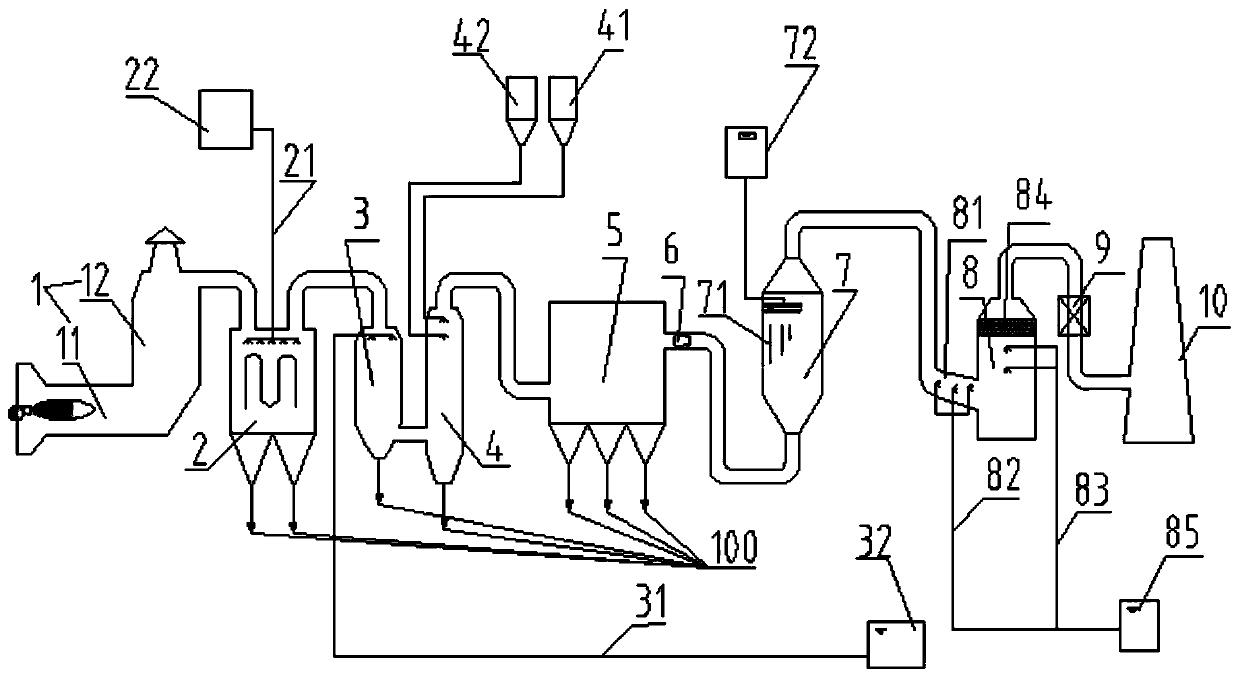

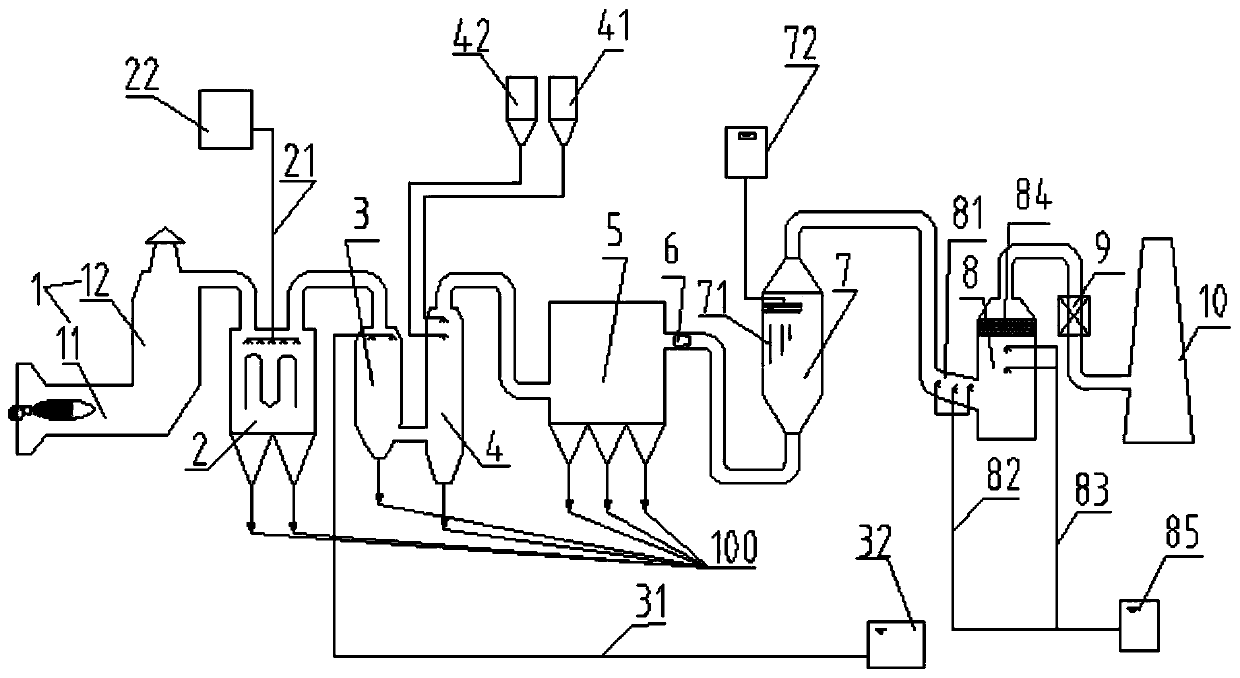

[0034] see figure 1 , the present invention provides a hazardous waste incineration flue gas purification system, including a rotary kiln 1, a waste heat boiler 2, a quench tower 3, a deacidification tower 4, a bag filter 5, a low-temperature plasma reaction device 7 and an absorption tower 8 connected in sequence; The rotary kiln 1 is used to incinerate hazardous waste; the inlet of the waste heat boiler 2 is equipped with an SNCR denitration agent atomization injection device 21, and the SNCR denitrification agent atomization injection device 21 is used to spray the denitrification agent to initially remove nitrogen oxides in the flue gas , the waste heat boiler 2 is used to recover t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com