Self-adaptive fuzzy control method for evaporation treatment of wet-method smoke desulphurization waste water

A wet flue gas desulfurization and self-adaptive fuzzy technology, which is applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of unsuitable flue gas evaporation capacity and blockage of evaporation and dust removal equipment , affect the effect of flue gas desulfurization and other issues, to achieve the effect of improving reliability, improving operating efficiency and reducing misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

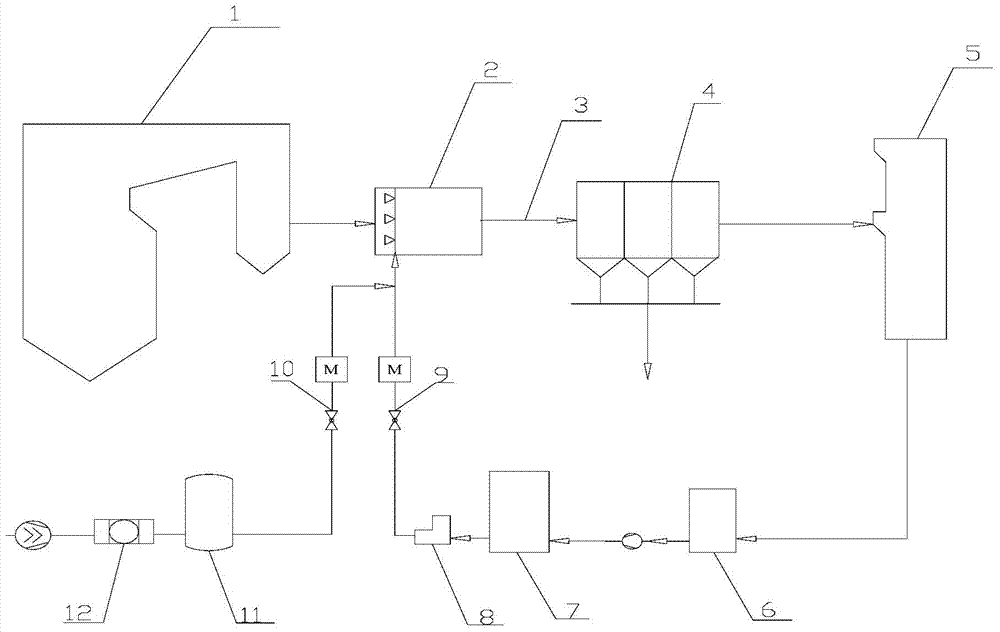

[0020] Such as figure 1 , The wastewater evaporation treatment process is that the flue gas generated by the combustion of the boiler 1 is connected to the dust collector 4 through the nozzle 3 and the flue 2 enters the dust collector 4. After dust removal, it enters the desulfurization absorption tower 5 for desulfurization. The waste water produced by desulfurization is sent to the waste water tank 6 of the desulfurization system. The waste water in the waste water tank 6 is pumped to the waste water buffer tank 7, and the outlet pipeline of the waste water buffer tank 7 is provided with a waste water high-pressure pump 8, and the waste water is sent to the waste water spray gun of the flue 2 by the waste water high-pressure pump 8. The compressed air generated by the other route air compressor 12 is sent to the compressed air tank 11 to stabilize the pressure and also sent to the waste water spray gun for atomizing waste water droplets. The compressed air and the waste wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com