Refuse landfill extraction well and leachate in-situ recharging composite system

A technology for a landfill and a composite system, which is applied in the field of a landfill gas extraction well and a leachate in-situ recharge composite system, can solve problems such as poor practicability, and achieve the advantages of simple structure, convenient construction and reduced efflux. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

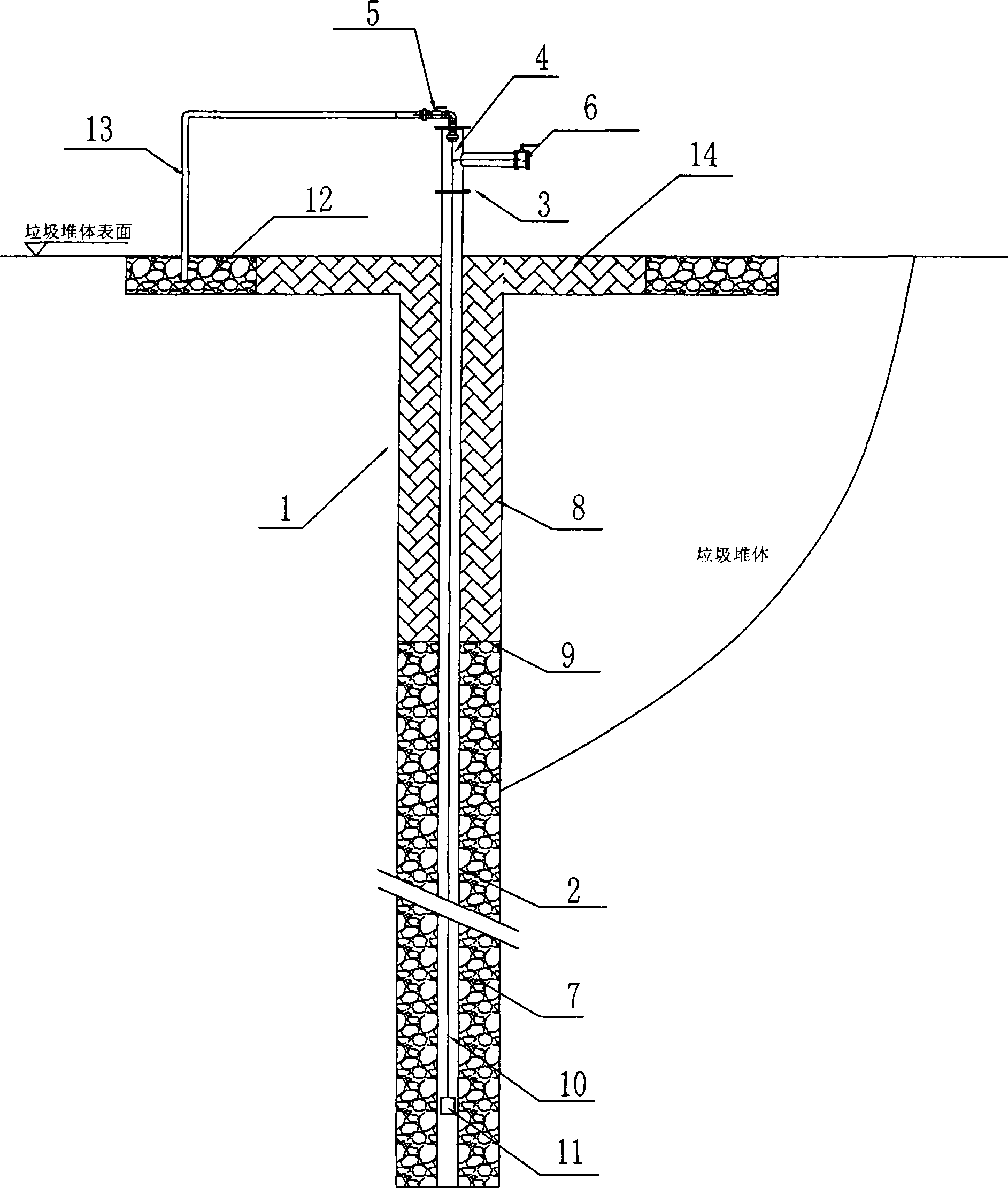

[0021] Such as figure 1 shown.

[0022] A compound system of gas extraction well and leachate in-situ recharge in landfill, which mainly consists of the following parts:

[0023] A gas extraction shaft 1, the gas extraction shaft 1 is formed by drilling or using a sleeve buried in the garbage dump to follow the garbage dump, with a diameter of 600mm-800mm and a depth of 10m-30m between;

[0024] An air extraction pipe 2, which is installed in the aforementioned air extraction shaft 1, has a diameter of 0.16-0.2 meters; it is made up of a solid wall pipe section of the upper section and a perforated floral pipe section of the lower section, wherein the length of the solid wall pipe section is 2 -3 meters; the upper end of the air extraction pipe 2 protrudes from the ground and is connected with a well head 4 through a flange 3, and a refill valve and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com