Processing system for implementing coking waste water reuse and processing method

A coking wastewater and treatment system technology, applied in metallurgical wastewater treatment, oxidized water/sewage treatment, chemical instruments and methods, etc., can solve the problem of adsorbent regeneration that is difficult to effectively solve, the treatment facility occupies a large area, and the final destination of the concentrate troubles and other problems, to achieve the effect of saving infrastructure costs, convenient operation and maintenance, and reducing fresh water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

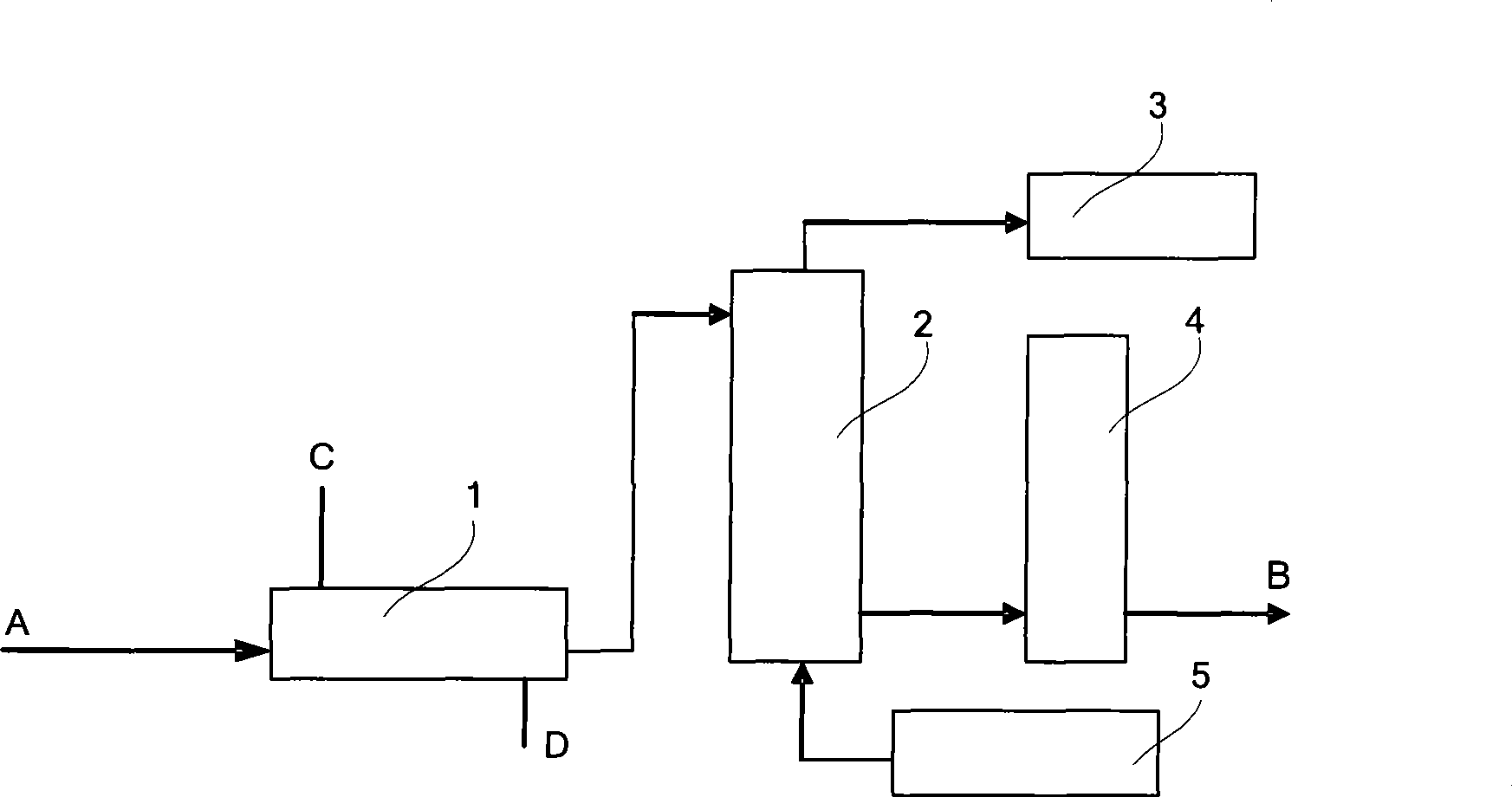

[0032] This embodiment provides a treatment system for realizing the reuse of coking wastewater, which is used to treat coking wastewater in a low-cost manner, so that the treated effluent can meet the reuse standard. The system is as follows: figure 1 shown, including:

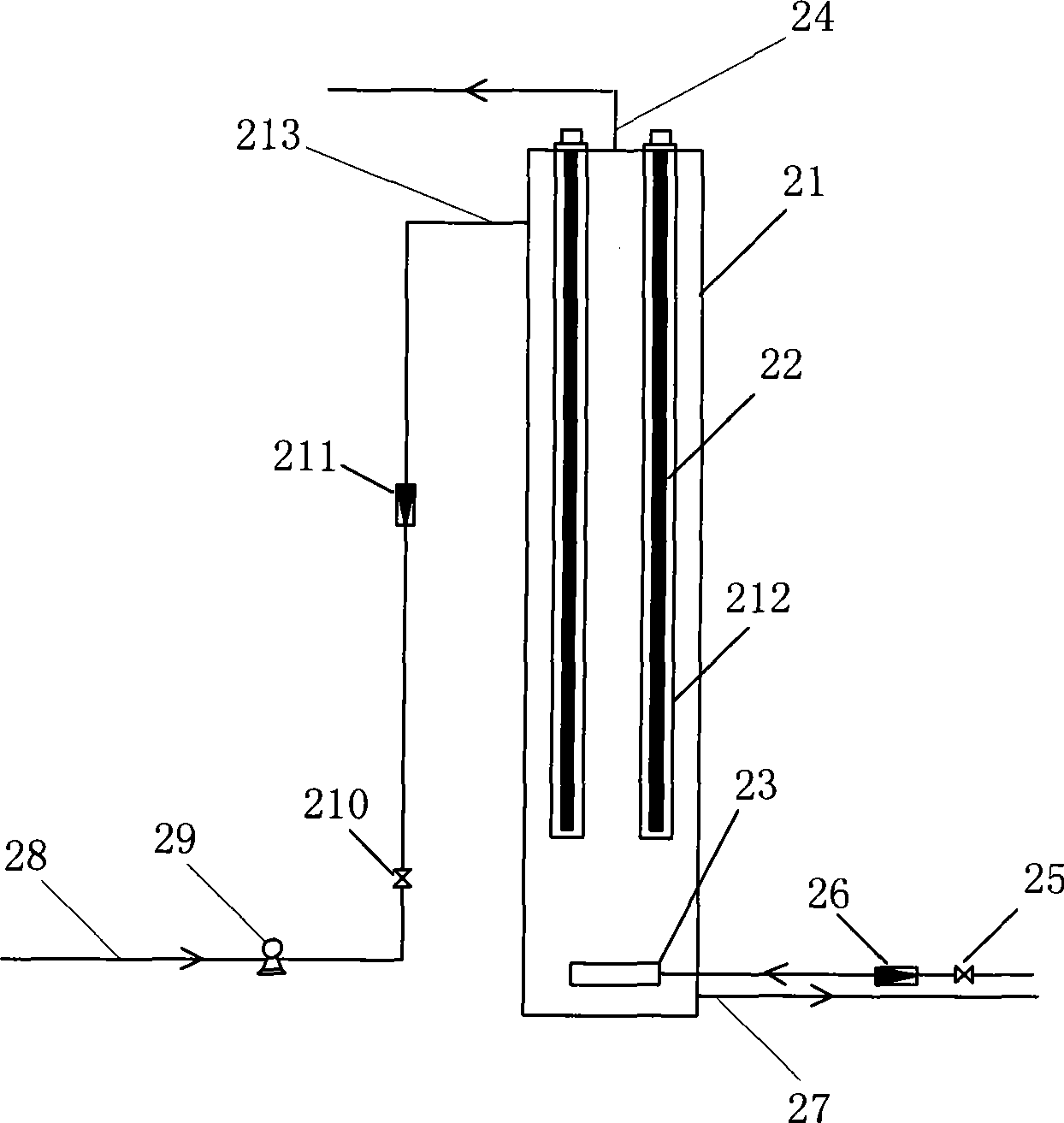

[0033] Coagulation sedimentation tank 1, photocatalytic O 3 Oxidation device and filtering device 4; Wherein, described coagulation sedimentation tank 1 is provided with the water inlet A that introduces biochemical effluent and sediment discharge port D, the water outlet of coagulation sedimentation tank 1 is connected with described photocatalysis O 3 Photocatalytic O by Oxidation Device 3 The water inlet provided on the upper part of the reactor 2 is connected, and the photocatalytic O 3 Photocatalytic O by Oxidation Device 3 The water outlet of the reactor 2 is connected to the water inlet of the filter device, and the filter device is provided with a water outlet B connected to a reuse pipeline. In pr...

Embodiment 2

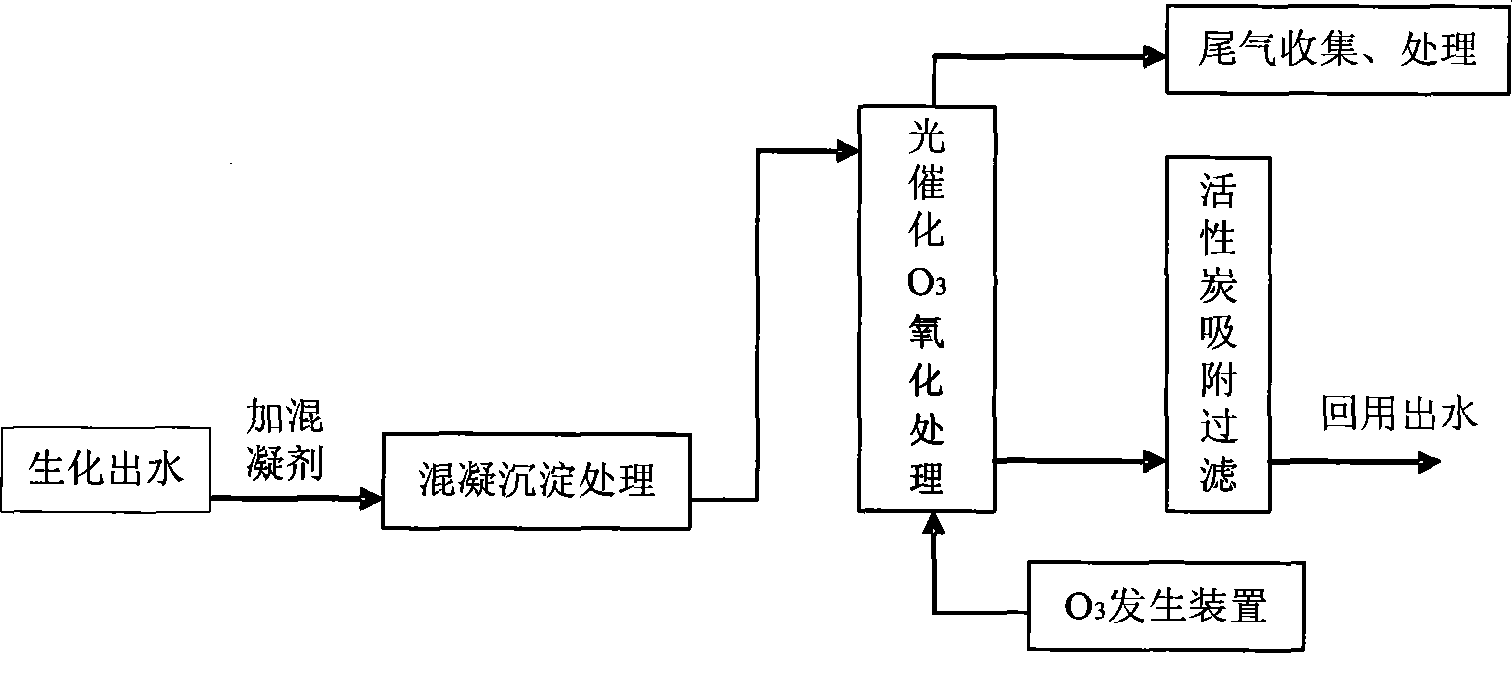

[0040] This embodiment provides a treatment method for realizing the reuse of coking wastewater, through coagulation, photocatalytic O 3 Oxidation and filtration three-stage process combination, advanced treatment of coking wastewater, specific as image 3 shown, including the following steps:

[0041] Coagulation and sedimentation treatment: add coagulant to the treated water body, stir and mix the reaction, and then let it stand for precipitation, so that the supernatant in the water body is separated from the sediment, the sediment is directly discharged, and the supernatant enters the subsequent step for photocatalytic O 3 oxidation treatment;

[0042] Photocatalytic O 3 Oxidation treatment: make the supernatant and aeration diffuse into tiny bubbles of O 3 The gas is fully contacted and reacted under the catalysis of ultraviolet light to complete the photocatalytic O 3 Oxidation treatment to remove pollutants in water;

[0043] Filtration treatment: for photocatalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com